Waste Tyre Pyrolysis Plant Vertical 4 TON

7,553 - 75,530 Per piece

1 piece (MOQ)

Waste Tyre Pyrolysis Plant Vertical Burhani Engineering Technology pyrolysis plants are intended for pyrolysis recycling wastes such as: Plastic, MSW, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. Modern Facility Our modern In-House Manufacturing Facilities with Designing & Engineering, Manufacturing and Testing of Products ensure Highest Product Quality Standards. Our Manufacturing Techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time Our State-of-the-Art Manufacturing Facilities are based in India

Country of Origin : India

Type : Waste Tyre Recycling Plant

Certification : ISO 9001:2008, CE Certified

Application : Waste Tyre Recycling

Condition : Used, New

Automatic Grade : Semi Automatic, Manual, Fully Automatic, Automatic

Power : 9-12kw, 6-9kw, 3-6kw, 1-3kw

Driven Type : Pneumatic, Hydraulic, Electric

Color : Sky Blue

Weight : 1

Voltage : 1

...more

Waste Tyre Pyrolysis Plant Vertical

7,553 - 75,530 Per piece

1 piece (MOQ)

Waste tyre pyrolysis plant vertical burhani engineering technology pyrolysis plants are intended for pyrolysis recycling wastes such as: plastic, msw, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. modern facility our modern in-house manufacturing facilities with designing & engineering, manufacturing and testing of products ensure highest product quality standards. Our manufacturing techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time our state-of-the-art manufacturing facilities are based in india

Country of Origin : India

Type : Waste Tyre Recycling Plant

Certification : ISO 9001:2008, CE Certified

Application : Waste Tyre Recycling

Condition : Used, New

Automatic Grade : Semi Automatic, Manual, Fully Automatic, Automatic

Power : 9-12kw, 6-9kw, 3-6kw, 1-3kw

Driven Type : Pneumatic, Hydraulic, Electric

Color : White

Weight : 1

Voltage : 2

...more

Vacuum Resin Trap Catch Pot

7,553 - 75,530 Per piece

1 piece (MOQ)

Vacuum Resin Trap Catch Pot Resin Infusion Catch Pot Resin Trap Burhani Engineering Technology Vacuum resin catch pot Professional Resin Infusion Catch Pot Resin Trap Professional high quality resin catch pot designed and manufactured by Burhani Engineering Technology Burhani Engineering Technology in India. This expertly engineered catch pot is designed to provide trouble free operation and service even in the busiest composites workshop. The resin infusion catch pot is manufactured from Annealed Powder Coated mild steel and base, for a hard wearing and chemical resistant finish. The Burhani Engineering Technology sturdy resin infusion catch pot features a laser finished 12 mm unbreakable clear lid which allow good visibility into the pot during usage. A heavy duty custom made silicone rubber provides positive seal and a high quality vacuum gauge with airtight resin line and Two vacuum line connections which are Inlet and Outlet. The resin trap vacuum chamber is designed so that paper liners are easily replaced to avoid fouling the inside of the pot. Burhani Engineering Technology also provide Liners to ensure resin vacuum trap chamber provides best performance with the availability of replacement Lids, Silicone Seals and pneumatic fittings. Sturdy 2mm Steel Construction Tough Powder Coated Finish None-Slip Rubber Feet Heavy Duty Positive Silicone Seal Laser Cut 10mm Clear Acrylic Lid Glycerin Filled Vacuum Gauge Resin Infusion Catch Pot Resin Trap Burhani Engineering Technology Vacuum resin catch pot Professional Resin Infusion Catch Pot Resin Trap Professional high quality resin catch pot designed and manufactured by Burhani Engineering Technology Burhani Engineering Technology in India. This expertly engineered catch pot is designed to provide trouble free operation and service even in the busiest composites workshop. The resin infusion catch pot is manufactured from Annealed Powder Coated mild steel and base, for a hard wearing and chemical resistant finish. The Burhani Engineering Technology sturdy resin infusion catch pot features a laser finished 12 mm unbreakable clear lid which allow good visibility into the pot during usage. A heavy duty custom made silicone rubber provides positive seal and a high quality vacuum gauge with airtight resin line and Two vacuum line connections which are Inlet and Outlet. The resin trap vacuum chamber is designed so that paper liners are easily replaced to avoid fouling the inside of the pot. Burhani Engineering Technology also provide Liners to ensure resin vacuum trap chamber provides best performance with the availability of replacement Lids, Silicone Seals and pneumatic fittings. Sturdy 2mm Steel Construction Tough Powder Coated Finish None-Slip Rubber Feet Heavy Duty Positive Silicone Seal Laser Cut 10mm Clear Acrylic Lid Glycerin Filled Vacuum Gauge

Country of Origin : India

Size : 1.1/2inch, 1.1/4inch, 1/2inch, 1inch, 2inch, 3/4inch, 4/5inch, 5/6inch, 6/7inch

Type : Vacuum Traps

Material : Alloy Steel, Carbon Steel, Forged Steel, Stainless Steel

Certification : ISI Certified, ISO 9001:2008 Certified

Color : Black, Brown, Grey, Sky Blue, White

Feature : Blow-Out-Proof, Casting Approved, Corrosion Proof, Durable, Good Quality, Investment Casting

Pattern : Dotted, Plain

Condition : New, Used

Finishing : Coated, Non Clated

End Connection : Butt Weld, Flanged, Screwed, Socket Weld Ends

Number of ways : 3way, 4way

Brand Name : BUHARINE

Classification : 1

Case Material : 1

Compressor : 1

...more

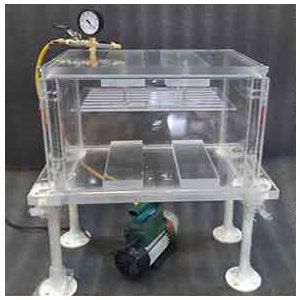

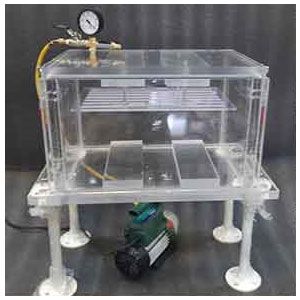

Vacuum Pressure Impregnation Chamber

7,553 - 75,530 Per piece

1 piece (MOQ)

Bubble Emission Leak Test Chamber Bubble Leak Testing Method using an acrylic vacuum chamber Bubble Emission Testing or Bubble Leak Test method is a procedure to detect leaks visually by immersing the test specimen in water. Burhani Engineering Technology is manufacturer of acrylic vacuum box leak testing device. We will discuss advantage and disadvantage of vacuum bubble leak emission test procedure and internal pressurization vacuum chamber. There are Two testing Methods which are commonly used in bubble leak testing methodologies adopted for bubble emission detection. These are : A. ASTM D 3078: Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission B. ASTM F 2096: Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test) What is a Bubble Leak Test Equipment ? Bubble testing is the least expensive and simplest method of assessing and detecting leaks. A differential pressure is created across the package with water chamber at lower pressure side and air on the high pressure side. Integrity Testing utilizing a Vacuum Chamber (ASTM D3078) Bubble Leak Testing using an acrylic vacuum chamber It is also known as submersion leak test, bubble emission leak test, under water leak test and dunking test. This a a methodology to detect and locate leaks in the specimen through bubble emission. Vacuum ASTM D3078 and Pressurized ASTMF2096 are the two ways to perform bubble emission leak test . The Burhani Engineering Technology bubble leak test equipment is an acrylic vacuum chamber which is transparent and enables full view of the interior during testing. The acrylic chamber is used with vacuum pump which can pull 30 inch Hg. Burhani Engineering Technology can also supply vacuum Chamber with Venturi pump. This can be used with pressurized air setup or a compressor. This venturi pump converts pressurized air into vacuum. Integrity Testing utilizing an Internal Pressurization System (ASTM F2096) The pressurized ASTMF2096 method is when the specimen is pressurized above the atmospheric pressure, based on the altitude of the test, the gauge pressure can be set to the required pressure value. The specimen is pressurized through feed tubes connected to a compressor during bubble leak test. There is a better leak detection due to pressurized air present inside the test specimen. But this is a time consuming and complex process. Also all test specimen get damaged due internal pressure and burst. While the vacuum test Method ASTMS3078 is the simplest and quick process. Product Catogories When a leak is detected in the test specimen, the air will start to flow from high pressure to lower pressure region . This is the reason the submerged part will emit air bubbles, which can be detected visually. A hole size of 0.001 inch or 0.025 mm can be detected with immersion leak test. The bubble leak test is accurate to of 10-3 atm-cc/sec. The accuracy of leak test is better than air decay leak test, pressure decay leak test, flow rate leak test dye penetration test. but it should not be compared with traces gas leak test, high vacuum leak test and gas sniffing methods according to bubble leak test standard. To recap, the advantages of bubble emission leak testing are: Cost Effective Seal Integrity Testing of bubble leak test meth

Country of Origin : India

Type : Vacuum Pressure Impregnation System

Certification : CE Certified, ISO 9001:2008 Certified

Application : Vacuum Use

Weight : 100-500kg, 1000-2000kg, 2000-4000kg, 500-1000kg

Color : Black, Brown, Grey, Light White

Voltage : 110V, 220V, 380V, 440V, 580V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Penaumatic

Warranty : 1yr, 2yrs, 5yrs

...more

Vacuum Degassing Chamber

7,553 - 75,530 Per Unit

1 Unit (MOQ)

Vacuum Degassing Chamber What is a vacuum degassing chamber? Vacuum degassing chamber manufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone. BURHANI ENGINEERING TECHNOLOGY RESIN VACUUM DEGASSING CHAMBER Vacuum degassing systems employ methods to maximize the surface area under vacuum. A resin degassing chamber is developed and manufactured by Burhani Engineering Technology in the Brand name of Burhani Engineering Technology. We also provide vacuum pump for degassing resin HOW DO YOU USE A VACUUM DEGASSING CHAMBER? The vacuum chamber with pump India is loaded with epoxy resin or silicon rubber or Polyurethane rubber. The Vacuum Pump is started and diy vacuum degassing chamber process is started and it continues for 8 to 10 minutes based on type of resin and quantity. HOW DOES VACUUM DEGASSING WORK WITH LAB1ST VACUUM CHAMBER? Vacuum Degassing silicone is a process to remove gases and bubbles from compounds using vacuum chamber and vacuum pump. A diy vacuum degassing chamber is required to assure a bubble free mold when mixing silicone rubbers and mixing resin and slower setting harder resins. ARE VACUUM CHAMBERS DANGEROUS? Burhani Engineering Technology Vacuum Chamber customers are using vacuum chamber degassing pot for degassing for over years without a single incident. WHAT WILL HAPPEN TO A HUMAN IN A VACUUM CHAMBER? Experiments on human and animals have shown that people can survive exposure to vacuum conditions for few minutes. Vacuums are lethal. Under extremely low vacuum air is trapped inside the lungs. It expands and tears the tender gas-exchange tissues HOW DO YOU MAKE A CHEAP VACUUM CHAMBER? HOW STRONG DOES A VACUUM CHAMBER NEED TO BE? You have to Select appropriate Vacuum Pump for your Acrylic Vacuum Chamber. The highest vacuum that can be expected in an acrylic vacuum chamber is about 750 mm hg. Burhani Engineering Technology also Provides option to go lower with a more powerful degassing chamber and pump WHAT IS INSIDE A VACUUM? A vacuum is space devoid of air. It is a region with air pressure less that atmospheric pressure. For example, a vacuum cleaner produces enough suction to reduce air pressure by around 20% around its occupied space. HOW MUCH DOES A RESIN DEGASSING VACUUM CHAMBER COST? A degassing chamber and pump can cost around $100-$1000 based on material, Sizes and shapes. You can do fun and science experiments to see how things react inside the vacuum. You can also have full viewing since the vacuum chamber price will be totally clear.

Country of Origin : India

Type : Vacuum Degasser

Material : Stainless Steel

Application : Industrial

Voltage : 110 V, 220 V

Condition : New

Frequency : 50-60 Hz

Warranty : 1 Yr, 2 Yrs

Automation Grade : Automatic, Semi-Automatic

Material : SS

...more

Vacuum Chamber

7,553 - 75,530 Per piece

1 Piece (MOQ)

Vacuum Chamber vacuum chamber is a space wherein the air and other gases are removed using a vacuum chamber. This Low pressure is called vacuum chamber. Research on Test and Mechanical components are carried out in vacuum chamber to check the performance of that space object. The BHFECH Large vacuum chambers are made up of various materials including aluminium, acrylic, stainless and other materials. 5 gallon vacuum chamber with pump manufactured by Burhani Engineering Technology is used for scientific experiments and it has multiple ports for viewing and instrumentation. Buna Rubber O-ring is used for sealing application is medium range vacuum chamber with pump. In high vacuum machines , we use machined knife edges which fits in tight into the copper gaskets with the help of flange bolts.

Country of Origin : India

Type : Vaccum Cooker

Material : Aluminium, Mild Steel, Stainless Steel

Application : Industrial Use

Weight : 300-500 Kg, 500-700 Kg

Color : Grey-black, Metallic, Shiny-silver, Silver

Voltage : 220V, 230V, 240V, 280V

Condition : New, Old

Capacity : 25-50 Kg, 50-75 Kg, 75-100 Kg

Finishing : Coated, Polished

Power Source : Electric

...more

Stainless Steel Cube Vacuum Chamber

7,553 - 75,530 Per piece

1 piece (MOQ)

Stainless Steel Cube Vacuum Chamber tainless Steel Cube Vacuum Chamber Product Features of the Chamber Body Made of Stainless Steel or Galvannealed Powder Coating. Acrylic Plexi-Glass chamber Door for long-term air-tightness performance. Burhani Vacuum chamber has a rounded edge at the top, for the protection of silicone gasket. Vacuum gauge is assembled on a separate port, so that the reading remains accurate even while pumping/venting the chamber. Gauge reading in both in Hg and Mpa. All kits are vacuum tested for 24 hours before packaging. (leakage less than 2.0 inHg at 24 hours) Two-sided flippable vacuum gasket for better durability and reliability. The gasket is chemically resistant to butane and other solvents. 25 mm thickness Acrylic lid for long life and clear visibility. Strong elastic food grade silicone vacuum hose can connect/disconnect easily with the pump/chamber. 50um air filter on the vent valve to reduce air flow and prevent any dust/powder flowing into the chamber. Easy to install and low-cost to maintain: the chamber can be assembled in 5 minutes. 45 day complimentary warranty and life-long parts support. Product Specs & Part List of the Chamber Vacuum Chamber: MS powder Coated or SS304. Door : Plexi Glass Acrylic with 30 years warranty. Vacuum Gasket: silicone, resistant to Butane and other solvents. Vacuum Gauge Assembly: 0.5 inHg accuracy. Valve Assembly: very high quality air-tight brass valves, with 50um filter on vent port. Vacuum Hose: 3.3' / 1 meter food grade collapse-proof silicone hose, 3mm wall thickness (8mm I.D, 14mm O.D) Vacuum Pump Adapter: 3/8" hose barb to 1/4 SAE flare port. . .

Country of Origin : India

Type : Stainless Steel Vacuum Bottles

Material : Stainless Steel

Shape : Oval, Rectangular, Round, Square

Certification : ISO 9001:2008 Certified

Color : Black, Blue, Green, Orange, Red, Sky Blue, White, Yellow

Pattern : Plain, Printed

Appearance : Antique, Modern

Packaging Type : Paper Box, Plastic Box

Storage Capacity : 10ltr, 1ltr, 250ml, 2ltr, 500ml

Brand Name : Burhani Engineering

Drinkware Type : 1

Metal Type : 1

...more

Pyrolysis of Rice Straw to create Biochar for Soil Amendment 5 TON

7,553 - 75,530 Per piece

1 piece (MOQ)

Pyrolysis of Rice Straw to create Biochar for Soil Amendment Burhani Engineering Technology pyrolysis plants are intended for Pyrolysis of rice straw to create biochar for soil amendment appears to be a promising method to address concerns with regard to improving soil fertility, increasing Carbon storage and decreasing Green House Gas emissions. The rice straw-derived biochars especially produced at 400 C had high alkalinity and cation exchange capacity, and high levels of available phosphorus and extractable cations. These properties indicate potential application of rice straw-derived biochar as a fertilizer and soil amendment

Country of Origin : India

Type : 1

Brand Name : Burhani Engineering

Application : 1

Classification : 2

CAS No. : 1

Other Names : 1

MF : 1

EINECS No. : 1

Release Type : 1

State : CHENNAI

Purity : 1

...more

Pyrolysis of Rice Straw to create Biochar for Soil Amendment 3 TON

7,553 - 75,330 Per piece

1 piece (MOQ)

Pyrolysis of Rice Straw to create Biochar for Soil Amendment Burhani Engineering Technology pyrolysis plants are intended for Pyrolysis of rice straw to create biochar for soil amendment appears to be a promising method to address concerns with regard to improving soil fertility, increasing Carbon storage and decreasing Green House Gas emissions. The rice straw-derived biochars especially produced at 400 C had high alkalinity and cation exchange capacity, and high levels of available phosphorus and extractable cations. These properties indicate potential application of rice straw-derived biochar as a fertilizer and soil amendment

Country of Origin : India

Type : Pyrolysis Plant

Certification : CE Certified, ISO 9001:2008

Application : Recycling Waste Plastic, Tyres

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 5000-6000kg, 6000-7000kg, 7000-8000kg, 8000-9000kg, 9000-10000kgf

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 21-24kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

...more

Pyrolysis of Rice Straw to create Biochar for Soil Amendment

7,553 - 75,530 Per piece

1 piece (MOQ)

Pyrolysis of Rice Straw to create Biochar for Soil Amendment Burhani Engineering Technology pyrolysis plants are intended for Pyrolysis of rice straw to create biochar for soil amendment appears to be a promising method to address concerns with regard to improving soil fertility, increasing Carbon storage and decreasing Green House Gas emissions. The rice straw-derived biochars especially produced at 400 C had high alkalinity and cation exchange capacity, and high levels of available phosphorus and extractable cations. These properties indicate potential application of rice straw-derived biochar as a fertilizer and soil amendment

Country of Origin : India

Type : Pyrolysis Plant

Certification : CE Certified, ISO 9001:2008

Application : Recycling Waste Plastic, Tyres

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 5000-6000kg, 6000-7000kg, 7000-8000kg, 8000-9000kg, 9000-10000kgf

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 21-24kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

...more

Plastic Pyrolysis Plant Vertical 5 TN

7,553 - 75,530 Per piece

1 piece (MOQ)

Plastic Pyrolysis Plant Vertical Burhani Engineering Technology pyrolysis plants are intended for pyrolysis recycling wastes such as: Plastic, MSW, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. Modern Facility Our modern In-House Manufacturing Facilities with Designing & Engineering, Manufacturing and Testing of Products ensure Highest Product Quality Standards. Our Manufacturing Techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time Our State-of-the-Art Manufacturing Facilities are based in India

Country of Origin : India

Type : Plastic Pyrolysis Plants

Certification : CE Certified, ISO 9001:2008

Application : Recycling Waste Plastic, Tyres

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 5000-6000kg, 6000-7000kg, 7000-8000kg, 8000-9000kg, 9000-10000kgf

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 21-24kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

Brand Name : Burhani Engineering

Material : 1

After-Sales Service Provided : 11

...more

Plastic Pyrolysis Plant Vertical

7,553 - 75,530 Per piece

1 piece (MOQ)

Plastic Pyrolysis Plant Vertical Burhani Engineering Technology pyrolysis plants are intended for pyrolysis recycling wastes such as: Plastic, MSW, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. Modern Facility Our modern In-House Manufacturing Facilities with Designing & Engineering, Manufacturing and Testing of Products ensure Highest Product Quality Standards. Our Manufacturing Techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time Our State-of-the-Art Manufacturing Facilities are based in India

Country of Origin : India

Type : Plastic Pyrolysis Plants

Certification : CE Certified, ISO 9001:2008

Application : Recycling Waste Plastic, Tyres

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 5000-6000kg, 6000-7000kg, 7000-8000kg, 8000-9000kg, 9000-10000kgf

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 21-24kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

Brand Name : Burhani Engineering

Material : 1

After-Sales Service Provided : 1

...more

Plasma Pyrolysis SYSTM

7,553 - 75,530 Per piece

1 piece (MOQ)

Plasma Pyrolysis System Plasma gasification system facilitates safe disposal of all type of organic wastes. The inorganic materials like glass, metals can also be minimized to slag. In plasma pyrolysis the most likely compounds which are produced include carbonaceous matter, methane, carbon monoxide, hydrogen, carbon dioxide and water molecules. These product gases are combustible. These can be either combusted or used as a heating source. The exhaust gases generated on combusting the product gases include CO2, N2, H2O. The product gases recovered has calorific and commercial values. These gases can be used as a heat source or as fuel. The amount of gas recovered depends solely upon type of waste and amount of waste. As the system can recover energy from the waste while safely disposing it, plasma pyrolysis can be treated as the ultimate waste management and recycling technology.

Country of Origin : India

Size : 52 Inches, 42 Inches, 32 Inches, 24 Inches, 20 Inches

Type : Plasma Display Panel

Application : Office, Hotel, Home

Weight : 45-50kg, 40-45kg, 35-40kg, 30-35kg, 25-30kg, 20-25kg

Color : Grey, Black

Feature : Smart TV, Low Power Consumption, Good Quality, Fully HD, Easy To Install, Easy Function

Voltage : 220V, 110V

Warranty : 3years, 2years, 1year

Brand Name : Philips

Interface Type : Burhani Engineering

Screen Size : 1

Response Time : 1

Brightness : 1

Contrast Ratio : 1

Resolution : 1

Pixels : 1

Products Status : 1

Tube Chip Color : 11

...more

Plasma Pyrolysis System

7,553 - 75,530 Per piece

1 piece (MOQ)

Plasma Pyrolysis System Plasma gasification system facilitates safe disposal of all type of organic wastes. The inorganic materials like glass, metals can also be minimized to slag. In plasma pyrolysis the most likely compounds which are produced include carbonaceous matter, methane, carbon monoxide, hydrogen, carbon dioxide and water molecules. These product gases are combustible. These can be either combusted or used as a heating source. The exhaust gases generated on combusting the product gases include CO2, N2, H2O. The product gases recovered has calorific and commercial values. These gases can be used as a heat source or as fuel. The amount of gas recovered depends solely upon type of waste and amount of waste. As the system can recover energy from the waste while safely disposing it, plasma pyrolysis can be treated as the ultimate waste management and recycling technology.

Country of Origin : India

Size : 52 Inches, 42 Inches, 32 Inches, 24 Inches, 20 Inches

Type : Plasma Display Panel

Application : Office, Hotel, Home

Weight : 45-50kg, 40-45kg, 35-40kg, 30-35kg, 25-30kg, 20-25kg

Color : Grey, Black

Feature : Smart TV, Low Power Consumption, Good Quality, Fully HD, Easy To Install, Easy Function

Voltage : 220V, 110V

Warranty : 3years, 2years, 1year

Brand Name : Philips

Interface Type : Burhani Engineering

Screen Size : 1

Response Time : 1

Brightness : 1

Contrast Ratio : 1

Resolution : 1

Pixels : 1

Products Status : CHENNAI

Tube Chip Color : WOOD

...moreLiquid Silicone Rubber

7,553 - 75,530 Per piece

1 piece (MOQ)

Liquid Silicone Rubber A Liquid Silicone Rubber material is a two-part platinum-cured elastomer that can be injected into a mold cavity to manufacture a part. LSR is very versatile in the elastomer industry and is seen across a whole spectrum of parts from consumer products to medical devices and everything in between. What is liquid silicone rubber used for? The most common application for silicone rubber is the production of LSR parts. LSR parts are used in a range of different industries. Their steam resistance and low compression set make them an excellent choice for gaskets and hardware in consumer appliances such as microwaves. Silicone is more expensive than most rubber types because it is a speciality high performance polymer with outstanding qualities. It is made in relatively low quantities and requires expensive and complicated primary manufacturing facilities.

Country of Origin : India

Size : Customized Size

Type : Liquid Silicone Rubber

Material : Liquid Silicone Rubber

Shape : Round, U Shape

Thickness : 0.5-1mm, 1.5-2mm, 2.5-3mm, 3.-5-4mm, 4.5-5mm

Color : Black, Blue, Brown, White

Packaging Type : Cartoons Box

Brand Name : Burhani

Certification : 1

CAS No. : 1

Other Names : 1

EINECS No. : 1

State : CHENNAI

Feature : READY

...more

Heated Vacuum Degassing Chamber

7,553 - 75,530 Per piece

1 Piece (MOQ)

Heated Vacuum Degassing Chamber Heated Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold when mixing resin and silicone rubbers and slower-setting harder resins, a vacuum chamber is required. A small vacuum chamber is needed to eliminate air bubbles for materials prior to their setting. The process is fairly straightforward. The casting or moulding material is mixed according to the manufacturers directions. Product Features of the Heated Vacuum Degassing Chamber Stainless steel chamber for long-term air-tightness performance. Heavy Duty Industrial Heating System. Adjustable Digital Temperature display and Controller. Various Temperature Ranges available on request. Burhani Vacuum chamber has a rounded edge at the top, for the protection of silicone gasket. Vacuum gauge is assembled on a separate port, so that the reading remains accurate even while pumping/venting the chamber. Gauge reading in both in Hg and Mpa. All kits are vacuum tested for 24 hours before packaging. (leakage less than 2.0 inHg at 24 hours). Two-sided flippable vacuum gasket for better durability and reliability. The gasket is chemically resistant to butane and other solvents. Stainless Steel lid for long life . Strong elastic food grade silicone vacuum hose can connect/disconnect easily with the pump/chamber. 50um air filter on the vent valve to reduce air flow and prevent any dust/powder flowing into the chamber. Easy to install and low-cost to maintain: the chamber can be assembled in 5 minutes. 45 day complimentary warranty and life-long parts support. Product Specs & Part List of the Chamber. Vacuum Chamber: stainless steel. Lid: Stainless Steel. Controller : Microprocessor based Digital Temperature controller. Vacuum Gasket: silicone, resistant to Butane and other solvents. Vacuum Gauge Assembly: 0.5 inHg accuracy. Valve Assembly: very high quality air-tight brass valves, with 50um filter on vent port. Vacuum Hose: 3.3' / 1 meter food grade collapse-proof silicone hose, 3mm wall thickness (8mm I.D, 14mm O.D) Vacuum Pump Adapter: 3/8" hose barb to 1/4 SAE flare port. . .

Country of Origin : India

Type : Vacuum Degasser

Material : Stainless Steel

Application : Industrial

Voltage : 110 V, 220 V

Condition : New, Used

Frequency : 50-60 Hz

Warranty : 1 Yr, 2 Yrs

Automation Grade : Automatic, Semi-Automatic

...more

Heated Vacuum Chamber / Oven

7,553 - 75,530 Per piece

1 piece (MOQ)

Heated Vacuum Chamber / Oven Heated Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold when mixing resin and silicone rubbers and slower-setting harder resins, a vacuum chamber is required. A small vacuum chamber is needed to eliminate air bubbles for materials prior to their setting. The process is fairly straightforward. The casting or moulding material is mixed according to the manufacturers directions. Product Features of the Heated Vacuum Degassing Chamber Stainless steel chamber for long-term air-tightness performance. Heavy Duty Industrial Heating System. Adjustable Digital Temperature display and Controller. Various Temperature Ranges available on request. Burhani Vacuum chamber has a rounded edge at the top, for the protection of silicone gasket. Vacuum gauge is assembled on a separate port, so that the reading remains accurate even while pumping/venting the chamber. Gauge reading in both in Hg and Mpa. All kits are vacuum tested for 24 hours before packaging. (leakage less than 2.0 inHg at 24 hours). Two-sided flippable vacuum gasket for better durability and reliability. The gasket is chemically resistant to butane and other solvents. Stainless Steel lid for long life . Strong elastic food grade silicone vacuum hose can connect/disconnect easily with the pump/chamber. 50um air filter on the vent valve to reduce air flow and prevent any dust/powder flowing into the chamber. Easy to install and low-cost to maintain: the chamber can be assembled in 5 minutes. 45 day complimentary warranty and life-long parts support. Product Specs & Part List of the Chamber. Vacuum Chamber: stainless steel. Lid: Stainless Steel. Controller : Microprocessor based Digital Temperature controller. Vacuum Gasket: silicone, resistant to Butane and other solvents. Vacuum Gauge Assembly: 0.5 inHg accuracy. Valve Assembly: very high quality air-tight brass valves, with 50um filter on vent port. Vacuum Hose: 3.3' / 1 meter food grade collapse-proof silicone hose, 3mm wall thickness (8mm I.D, 14mm O.D) Vacuum Pump Adapter: 3/8" hose barb to 1/4 SAE flare port. . .

Country of Origin : India

Type : Hand Pliers

Material : Cast Steel, Iron, Metal, Mild Steel, Stainless Steel

Thickness : 1.5-2mm, 2.5-3mm, 3.5-4mm, 4.5-5mm, 5.5-6mm, 6.5-7mm, 7.5-8mm, 8.5-9mm, 9.5-10mm

Length : 10inch, 12inch, 5inch, 8inch

Application : Construction, Domestic

Weight : 0-2kg, 2-5kg, 5-10kg

Grade : AISI, ASTM, BS, DIN, GB, JIS

Color : Black, Grey, Silver, Yellow

Feature : Best Quality, Easy To Use, Fine Finished, Foldable, High Durability, High Performance, High Tensile Strength, Light Weight, Rust Free Nature

Surface : Non Polished, Polished

Automation Grade : Manual

Brand Name : Jayati

...more

Heated Vacuum Chamber

7,553 - 75,530 Per piece

1 piece (MOQ)

Heated Vacuum Chamber / Oven Heated Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold when mixing resin and silicone rubbers and slower-setting harder resins, a vacuum chamber is required. A small vacuum chamber is needed to eliminate air bubbles for materials prior to their setting. The process is fairly straightforward. The casting or moulding material is mixed according to the manufacturers directions. Product Features of the Heated Vacuum Degassing Chamber Stainless steel chamber for long-term air-tightness performance. Heavy Duty Industrial Heating System. Adjustable Digital Temperature display and Controller. Various Temperature Ranges available on request. Burhani Vacuum chamber has a rounded edge at the top, for the protection of silicone gasket. Vacuum gauge is assembled on a separate port, so that the reading remains accurate even while pumping/venting the chamber. Gauge reading in both in Hg and Mpa. All kits are vacuum tested for 24 hours before packaging. (leakage less than 2.0 inHg at 24 hours). Two-sided flippable vacuum gasket for better durability and reliability. The gasket is chemically resistant to butane and other solvents. Stainless Steel lid for long life . Strong elastic food grade silicone vacuum hose can connect/disconnect easily with the pump/chamber. 50um air filter on the vent valve to reduce air flow and prevent any dust/powder flowing into the chamber. Easy to install and low-cost to maintain: the chamber can be assembled in 5 minutes. 45 day complimentary warranty and life-long parts support. Product Specs & Part List of the Chamber. Vacuum Chamber: stainless steel. Lid: Stainless Steel. Controller : Microprocessor based Digital Temperature controller. Vacuum Gasket: silicone, resistant to Butane and other solvents. Vacuum Gauge Assembly: 0.5 inHg accuracy. Valve Assembly: very high quality air-tight brass valves, with 50um filter on vent port. Vacuum Hose: 3.3' / 1 meter food grade collapse-proof silicone hose, 3mm wall thickness (8mm I.D, 14mm O.D) Vacuum Pump Adapter: 3/8" hose barb to 1/4 SAE flare port. . .

Country of Origin : India

Type : Hand Pliers

Material : Cast Steel, Iron, Metal, Mild Steel, Stainless Steel

Thickness : 1.5-2mm, 2.5-3mm, 3.5-4mm, 4.5-5mm, 5.5-6mm, 6.5-7mm, 7.5-8mm, 8.5-9mm, 9.5-10mm

Length : 10inch, 12inch, 5inch, 8inch

Application : Construction, Domestic, Industrial

Weight : 0-2kg, 2-5kg, 5-10kg

Grade : AISI, ASTM, BS, DIN, GB, JIS

Color : Black, Grey, Silver, Yellow

Feature : Best Quality, Easy To Use, Fine Finished, Foldable, High Durability, High Performance, High Tensile Strength, Light Weight, Rust Free Nature

Surface : Non Polished, Polished

Automation Grade : Manual

Brand Name : Jayati

...more

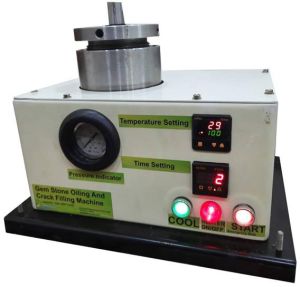

Gem Stone Oiling And Crack Filling Machine

7,553 - 75,530 Per piece

1 piece (MOQ)

gem stone oiling and crack filling machine burhani engineering technology is the largest producer and manufacturer of state of art high pressure and low temperature gemstone. oiling and crack filling machine. the gemstone crack filling machine is a compact and desktop model that works in any environment. the burhani engineering technology oiling apparatus is used to induce resins, oils, paraffin, oleoresins and combination of compatible liquid fillers of different viscosity into the surface reaching cracks and fissures on sapphire, ruby, emerald, tourmaline and many more. the above process helps to produce enhance clarity in the gemstone by hiding their imperfections by increasing their diaphaneity. burhani engineering technology is the largest producer and manufacturer of state of art high pressure and low temperature gemstone. oiling and crack filling machine. the gemstone crack filling machine is a compact and desktop model that works in any environment. stainless steel 304 chamber to load, heat and pressurize the stones. pressure gauge with on -off valve and pneumatic fittings. temperature controller with instruments. 2 stage vacuum pump with gauge, hose and fittings. features & specifications it is a bench top compact model. the net weight of the machine is 45 kgs. the recommended temperature range of operation is from 25 degree c to 100 degree c. maximum designed pressure is 600 bar which is equivalent to 8700 psi. loading capacity in one shift is 1000 carats of various gemstone of full load. the chamber is made up of heavy duty stainless steel material. 2 stage heavy duty vacuum pump is also included in the package. digital and programmable control unit to control pressure and temperature using ssr and sensor. 500 watts heater is used inside the machine at 220 v ac and 50 hz 250 watts of current is required to maintain 3800 psi. below is the example of temperature-pressure correlation values using paraffin oil. 75oc 100 bar-1450 psi 80oc 130 bar-1885 psi 85oc 150 bar-2175 psi 90oc 200 bar-2900 psi 95oc 230 bar-3336 psi 120oc 260 bar-3771psi 150oc 300 bar-4351psi note: above pressure and temperature values shall vary depending on the load, amount and type of the filler oil used in the burhani engineering technology crack filling chamber, and other variable process parameters. 1. what is the oiling and crack filling process followed in gemstones? the oiling and crack filling process is aimed to reduce the visibility of surface reaching fissures, cracks, crevices and other dislocation features in the gemstone. thus the oil treatment enhances the clarity of gemstone and improves its overall appearance, and thus increases its price. 2. which type of gemstones are suitable for oiling? rubies, sapphire, diamonds, emerald, opal, turquoise, rhodochrosite. many other gemstone porus and non porus can be oiled. many porous and non-porous gems may be oiled. 3. which quality of the gemstone are oiled? all qualities of gemstone can be subjected to the oiling treatment as long as the stone has surface reaching fractures. 4. are only cut and polished gemstones subject to oiling process? cut and polished gemstones and rough stones can be oiled in different ways. 5. how significant is clarity improvement in the oiled gemstones. the clarity can be improved from minor to minor to significant change and in some cases there shall be no improvement. many clarity grades are published by various gem institute. these are subjected to experiments and research. 6. is the oiling process in gemstones permanent? the oiling process may be permanent if the hardener is used with fillers. the gemstone should be re-oiled, if the oil is leaked from the gemstone. 7. is the oiling process in gemstones reversible? the oiling process can be reversed based on filler material used. if hardener is combined with filler, then it may be difficult to reverse or remove from the gemstone. 8. if the oiling treatment detectable? the oiling

Country of Origin : India

Size : 0-10mm, 10-20mm, 20-30mm, 30-40mm, 40-50mm

Type : Gem Stones

Material : Gemstone, Natural Stone, Stone

Application : Jewellery

Color : Blue, Green, Purple, Red

Feature : Anti Corrosive, Colorful Pattern, Durable, Fadeless, Shiny Looks, Sturdiness

Finishing : Non Polished, Polished

Gemstone Shape : Oval, Round, Square

Stylish : Common, Fashionable

Brand Name : Burhani engineering

Shape : round

Certification : i yes o

Weight : 20 k

Condition : new

Gemstone Type : 1

Gemstone Color : 1

Gemstone Size : 1

Properties : 1

Warranty : 1

Optical Special Effects : 1

...more

Epoxy Resin pressure pot

7,553 - 75,530 Per piece

1 piece (MOQ)

Epoxy Resin Epoxy refers to any of the basic components or cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. Epoxy resin, mixed with pigment, may be used as a painting medium, by pouring layers on top of each other to form a complete picture. It is also used in jewelry, as a doming resin for decorations and labels, and in decoupage type applications for art, countertops, and tables. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paint brush manufacturing, fiber-reinforced plastic materials, and adhesives for structural and other purposes. Product Catogories Burhani Engineering Technology Produces 3 Types of Epoxy Resin Ultra High Gloss Clear Transparent Epoxy Resin Clear Casting resin Polyester based Epoxy Resin For Potting Of Electronic Components

Country of Origin : India

Type : Epoxy Resins

Brand Name : BURHANI

Application : Artficial Wood, Automobiles, Cement, Coating In Paint, Concrete Coating, Flooring, Home, Household, Industrial, Industry, Paint

Feature : Anti-wrinkle, Dry Cleaning, Easily Washable, Eco-friendly, Good Look, Good Quality, Impeccable Finish, Quick-dry, Safe Use

Condition : New, Used

...more

Carbonization Furnace

7,553 - 75,530 Per piece

1 piece (MOQ)

Carbonization Furnace Burhani Engineering Technology Carbonization is a process to make charcoal from Biomass. Burhani Engineering Technology Manufactures World Class Equipment for carbonization to increase calorific value of the End Product Charcoal Almost all the biomass can be made into charcoal, we list some as follow: Wood logs, wood branches, sawdust briquettes, biomass waste, coconut shell, Macadamia nut, cashew nut shell, bamboo, etc

Country of Origin : India

Type : Furnaces

Material : Aluminum, Iron, Plastic, Stainless Steel

Certification : CE Certified, ISO 9001:2008 Certified

Application : Heating Process

Weight : 100-300kg, 1000-1500kg, 1500-2000kg, 2000-2500kg, 300-500kg, 500-700kg, 700-1000kg

Color : Black, Blue, Brown, Green, Red, White

Voltage : 110V, 220V, 230V, 380V, 440V, 450V

Condition : New, Used

Power : 1-3kw, 12-15kw, 15-18Kw, 18-21Kw, 21-24Kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1yrs, 2yrs, 3yrs, 5yrs

Automation Grade : Automatic, Fully Automatic, Manual, Semi Automatic

...more

Bubble Emission Leak Test Chamber

7,553 - 75,530 Per piece

1 PRICE (MOQ)

Bubble Emission Leak Test Chamber Bubble Leak Testing Method using an acrylic vacuum chamber Bubble Emission Testing or Bubble Leak Test method is a procedure to detect leaks visually by immersing the test specimen in water. Burhani Engineering Technology is manufacturer of acrylic vacuum box leak testing device. We will discuss advantage and disadvantage of vacuum bubble leak emission test procedure and internal pressurization vacuum chamber. There are Two testing Methods which are commonly used in bubble leak testing methodologies adopted for bubble emission detection. These are : A. ASTM D 3078: Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission B. ASTM F 2096: Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test) What is a Bubble Leak Test Equipment ? Bubble testing is the least expensive and simplest method of assessing and detecting leaks. A differential pressure is created across the package with water chamber at lower pressure side and air on the high pressure side. Integrity Testing utilizing a Vacuum Chamber (ASTM D3078) Bubble Leak Testing using an acrylic vacuum chamber It is also known as submersion leak test, bubble emission leak test, under water leak test and dunking test. This a a methodology to detect and locate leaks in the specimen through bubble emission. Vacuum ASTM D3078 and Pressurized ASTMF2096 are the two ways to perform bubble emission leak test . The Burhani Engineering Technology bubble leak test equipment is an acrylic vacuum chamber which is transparent and enables full view of the interior during testing. The acrylic chamber is used with vacuum pump which can pull 30 inch Hg. Burhani Engineering Technology can also supply vacuum Chamber with Venturi pump. This can be used with pressurized air setup or a compressor. This venturi pump converts pressurized air into vacuum. Integrity Testing utilizing an Internal Pressurization System (ASTM F2096) The pressurized ASTMF2096 method is when the specimen is pressurized above the atmospheric pressure, based on the altitude of the test, the gauge pressure can be set to the required pressure value. The specimen is pressurized through feed tubes connected to a compressor during bubble leak test. There is a better leak detection due to pressurized air present inside the test specimen. But this is a time consuming and complex process. Also all test specimen get damaged due internal pressure and burst. While the vacuum test Method ASTMS3078 is the simplest and quick process. When a leak is detected in the test specimen, the air will start to flow from high pressure to lower pressure region . This is the reason the submerged part will emit air bubbles, which can be detected visually. A hole size of 0.001 inch or 0.025 mm can be detected with immersion leak test. The bubble leak test is accurate to of 10-3 atm-cc/sec. The accuracy of leak test is better than air decay leak test, pressure decay leak test, flow rate leak test dye penetration test. but it should not be compared with traces gas leak test, high vacuum leak test and gas sniffing methods according to bubble leak test standard. To recap, the advantages of bubble emission leak testing are: Cost Effective Seal Integrity Testing of bubble leak test method Simple and Easy Leak Test Practical Testing of Leaking Pouches and Packages Visual Detection and Location of Package Leaks Quick Sample Preparation of vacuum bubble test Versatile Testing Method of vacuum leak test procedure The bubble leak test can be utilized on variously shaped and sized specimen - whether that may be a pouch, tray, box, vial, bottle, etc…

Type : Bubble Leak Testing

Certification : CE Certified, ISO 9001:2008

Application : Industrial Use, Leak Testing

Weight : 100-200kg, 200-300kg, 300-400kg, 400-500kg

Color : Brown, Grey, Light White, White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

...more

Biomass Pyrolysis Plant Vertical 5 TON

7,553 - 75,530 Per piece

1 piece (MOQ)

Biomass Pyrolysis Plant Vertical Burhani Engineering Technology pyrolysis plants are intended for pyrolysis recycling wastes such as: Plastic, MSW, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. Modern Facility Our modern In-House Manufacturing Facilities with Designing & Engineering, Manufacturing and Testing of Products ensure Highest Product Quality Standards. Our Manufacturing Techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time Our State-of-the-Art Manufacturing Facilities are based in India

Country of Origin : India

Type : Pyrolysis Plant

Certification : CE Certified, ISO 9001:2008

Application : Recycling Waste Plastic, Tyres

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 5000-6000kg, 6000-7000kg, 7000-8000kg, 8000-9000kg, 9000-10000kgf

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 21-24kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year, 2years, 5years

...more

Biomass Pyrolysis Plant Vertical

7,553 - 75,530 Per piece

1 piece (MOQ)

Biomass Pyrolysis Plant Vertical Burhani Engineering Technology pyrolysis plants are intended for pyrolysis recycling wastes such as: Plastic, MSW, rubber wastes, waste plastics, used tires, wood waste, soil contaminated by oil sludge, mazut, bitumen, oil sludge, medical waste, etc. Modern Facility Our modern In-House Manufacturing Facilities with Designing & Engineering, Manufacturing and Testing of Products ensure Highest Product Quality Standards. Our Manufacturing Techniques ensures efficient and time saving method of manufacturing to meet customer requirement on shorter lead time Our State-of-the-Art Manufacturing Facilities are based in India

Country of Origin : India

Type : Bio Mass Plant

Certification : CE Certified, ISO 9001:2008

Application : Industrial

Weight : 10000-15000kg, 15000-20000kg, 20000-25000kg, 5000-10000kg

Color : Black, Blue, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V, 550V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Mechanical

Warranty : 1year, 2years, 5years

Brand Name : Burhani Engineering

After-Sales Service Provided : 1

Logo : 1

...moreBe first to Rate

Rate ThisOpening Hours