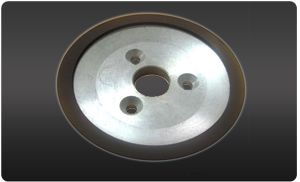

ELECTROMILL DIAMOND AND CBN GRINDING WHEELS

Get Price Quote

ElectroMill diamond and CBN electroplated grinding wheels replace expensive, complex indexable tungsten carbide or PCD milling cutters in high volume production finishing applications by consistently providing accurate flatness and part tolerances. With the right machine tool conditions and speed/feed parameters, throughput is significantly increased and tool costs, tool changeover and down-time cycles are dramatically reduced. ElectroMill can be successfully applied in marine, small-engine, automotive, off-road, agriculture, aerospace, defense and other industries – across a wide variety of components as well as ferrous, non-ferrous and exotic materials. Advantages:• Tool life of the ElectroMill has proven to be 50,000 pieces, consistently.• The mills are then sent back to Santechnik for strip and replate.• Tool quality, dimensional accuracy and life repeatability are the same as the original mill.

CBN DIAMOND WHEELS

500 Per Piece

Best Deals from Cbn Grinding Wheel

Cbn Grinding Wheel

Get Price Quote

BOND IN CRANKSHAFT AND CYLINDRICAL CBN wheels

Get Price Quote

Shree Diamond Tool provides vitrified bond CBN wheels for grinding the automobile camshafts, crankshafts and cylinder in air-compressor industry. Optimum bond specifications have been set for each type of cam material. The wheels are used for high-speed grinding, thus the bond quality, adhesives and the materials used for the core are carefully designed for safety. Performance Highly accurate and highly efficient High grade abrasive grits and bonding powder Perfect dressing ability in controlling surface finish and grinding efficiency Workpiece : camshaft, crankshaft

CBN Grinding Wheels

Get Price Quote

Resin BondedMetal BondedSinterex BondedElectroplated

CBN TOOLS AND WHEELS

Get Price Quote

This is a Diamond / CBN Wheel For your wheel to work efficiently – Keep speed to within 4500-6000 S.F.P.M.– True the Wheel to spindle before starting operation.– Restrict depth of cut to 0.001” per pass.– Use coolant wherever possible but use of coolant is a must for metal Bonded Wheels.– Avoid Steel and Bronze materials as much as possible, when you are using a Diamond Wheel.– For Flared Cup wheels having Diamond Cross-section in ‘V’ position, provide continuous relief to Diamond from Aluminum from the inside diameter.– Avoid loading of wheel by exposure of clear cutting surface thru clearing by green silicon carbide stick during use whenever required for Resin and Metal Bonded Wheels and by a brush under water for Electro-plated wheels.– Use wheel guard during grinding operation.

CBN Grinding Wheels

Get Price Quote

CBN Grinding Wheels, Diamond Grinding Wheels, industrial diamond products

cbn vitrified wheels

Get Price Quote

cbn vitrified wheels, FORM DRESSERS, CONICAL DRESSERS

Cbn Grinding Wheel

Get Price Quote

Cbn Grinding Wheel, Electroplated Diamond Slitting Saws

Cbn Grinding Wheel

Get Price Quote

Cbn Grinding Wheel, Diamond Grinding Wheels, metal bond wheels

Vitrified Diamond CBN Wheel

Get Price Quote

Vitrified Diamond CBN Wheel, Diamond Flaring Cup Wheel