Continuous Stirred Tank Reactor

125,000 - 1,700,000 Per no

1 Piece (MOQ)

Chemical Process Reactor

250,000 Per unit

Best Deals from Chemical Reactors

Line Reactor

10,000 Per Piece

Fluidized Bed Bio-Reactors

Get Price Quote

In Fluidized Bed Reactors, cells are "immobilized" in small particles which move with the fluid. The small particles create a large surface area for cells to stick to and enable a high rate of transfer of oxygen and nutrients to the cells. The fluidized bed reactor is most suitable when a high viscosity substrate solution and a gaseous substrate or product are used in a continuous reaction system. Here also we have four phases in treatment i.e. Preliminary treatment, Primary, Secondary & Tertiary Treatment. Preliminary Treatment In Preliminary treatment removal of contents as Poly-ethenes, Papers, fibres, Vegetable & edible pieces, grits, Oil � grease etc. by bar Screening chambers & Oil-trapping is carried out in the equalization sump. Primary Treatment In the next Primary Treatment stage we go for chemical treatment for adjusting ph and this chemical dosing is optional will depend on the raw water. Secondary Treatment In the secondary Treatment Removal of organic matters suspended solids by Biological treatment, decomposition and Clarifications are carried out with specialized attached growth biological treatment technology. Here the Biological action takes place in aeration tank , tube settlers and the clarified water is passed to chlorine contact tank. Tertiary Treatment In the Tertiary Treatment the water from chlorine dosing tank is allowed to settle in buffer tank. From Buffer tank the water is pumped to sand filter & carbon filters respectively. Features Removes hydrocarbons and BOD/COD.Uses oxygen transfer with a large protected biofilm attachment area.Incorporates neutrally-buoyant Media Pac.CompactNo/Less Civil work.Low Operational cost.Easy Maintenance & Operations.Portability.Reduced Noise.Quick InstallationMin Sludge

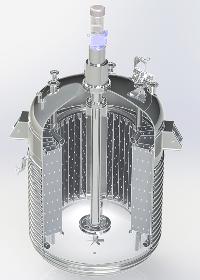

Continuous Stirred Tank Reactor

Get Price Quote

To study the progress of a Chemicals reaction CSTR To determine the Reaction Rate Constant Product Code : SAMS CHE - 002

Frp Chemical Reactor

Get Price Quote

Leveraging on our technologically advanced infrastructure, we have become a premier manufacturer of a wide range of qualitative fiber Storage Tanks which includes PP-FRP Tank, PVC-FRP Tank and FRP Tank. Our range complies with different specifications of domestic and international standard and is well acknowledged for durability and dimensional accuracy. All These products are used for the storage of Acids, Alkalis and Solvents in bulk quantity. Our manufactured range is widely applauded for features such as Non-corrosive

Structured Packings

Get Price Quote

Structured Packings, waterproof corrugated box, Heavy Duty Corrugated Boxes

Limpet Coil Reactor

Get Price Quote

Limpet Coil Reactor, reaction kettles

agitated reactors

Get Price Quote

acid filling machines, Resin Plant, chemical injection skid

MS reactors

Get Price Quote

MS reactors, Non-IBR boiler, Ms Tanks, Reactors

UV Reactor

Get Price Quote

UV Reactor, White Light Lamp

Chemical Reactors

Get Price Quote

chemical process equipments, ptfe linings, Condensers, Centrifugal Fans

PhCR Photo Chemical Reactor

Get Price Quote

PhCR Photo Chemical Reactor, Pharmaceutical Vaccine Refrigerator, butyrometer

Rubber Lined Reactor

Get Price Quote

Rubber Lined Reactor, tank liners, Rubber Lining Valve

Chemical Reactors

Get Price Quote

image processing