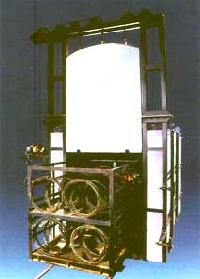

Continuous Mesh Belt Furnace

200,000 - 500,000 Per per unit

1 pe (MOQ)

JR FURANCE offers Mesh Belt Conveyor Furnaces which will be used for Continuous Copper Brazing, Silver Brazing and Annealing up to 1150°C If you produce light or medium weight parts where low cost, high volume production is required; JR FURNACE Mesh belt furnace will process your work efficiently and economically, typically free of oxidation and discoloration with less scale than other processes.

Rotary Retort Continuous Hardening

Get Price Quote

Rotary Retort Continuous Hardening & Tempering Plants furnace for mass produced parts, especially spherical and cylindrical that tend to roll Process Capabilities Annealing (non ferrous) Through Hardening Shallow Case Hardening Equipment Features Electric or gas heated Auto loading Rotary prewash & postwash Atmosphere lock at inlet Cast alloy rotary retort Corrugated strip or radiant tube heating Oil or polymer quench Mesh belt or magnetic quench conveyor Rotary 2 pass tempering with fan

Best Deals from Continuous Furnaces

Continuous Melting Furnace

Get Price Quote

Continuous Furnace

Get Price Quote

We are offering continuous furnace. we are providing continuous mesh belt furnaces with exo gas systems to our customers'. Offered in different specifications, shapes, sizes, these available in both gas fired and electrically heated versions. Further, these systems are known for strength as well as high durability and find process suitability for hardening, carburizing with integral endo gas generator, rinsing, internal quenching, washing and tempering based applications.these are famous for their fine quality and are provided with fully automatic system through plc, with hmi; which is controlled through computers. types pusher type furnaces roller hearth furnace walking beam furnaces conveyor type furnace continuous mesh belt furnace continuous tempering and hardening lines application heat treatment for bearing, needles, automobile parts, brazing, chain parts, fasteners, springs circlips features hardening carburising with integral endo gas generator internal quenching rinsing washing and tempering with fully automatic system through plc with hmi and controlled through computer

Continuous Mesh Belt Furnace

Get Price Quote

Application: Heat Treatment for Bearing, Needles, Automobile Parts, Brazing, Chain Parts, Fasteners, Springs Circlips Features: Hardening, Carburising with Integral Endo Gas Generator, Internal Quenching, Rinsing, Washing And Tempering, With Fully Automatic System Through Plc With Hmi And Controlled Through Computer Heating Mode: Electrical and GasTemperature: Up to 1200 Deg C Control Panel: With Slc and Plc Integrated System

Mesh Belt Continuous Furnace

Get Price Quote

Mesh Belt Continuous Furnace, Bell Type Furnace, Bogie Hearth Furnace

continuous carburising furnace

Get Price Quote

continuous carburising furnace, austempering furnace, Heat Treatment Furnaces

continuous furnaces

Get Price Quote

continuous furnaces, Furnace Accessories, Industrial Oven

Mesh Belt Continuous Furnace

Get Price Quote

We deals in manufacturing of wide range of Mesh Belt Continuous Furnace.