GMT THREADING INSERTS

Get Price Quote

GMT the World's Most Comprehensive Range of Carbide Threading Inserts. None of the large cemented carbide manufacturers have anywhere near the same range as that available from GMT. The reason is simple. Threading is a fairly small part of all machining operations, and has been neglected by major carbide companies who offer only a limited range of the most common profiles. On the other hand GMT has a range that covers all of the threads used throughout the world. The main product range is concentrated on inserts and toolholders for threading. In simpe terms, GMT is a specialist.

Carbide Inserts

Get Price Quote

Best Deals from Cutting Tool Inserts

Grooving Inserts

Get Price Quote

Apmt 1135 Pdtr Nn Lt30 lamina carbide milling insert

Get Price Quote

We offer apmt 1135 pdttr nn lt30. Milling insert

Pcbn Inserts

Get Price Quote

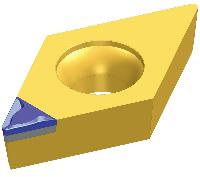

Turning Insert

Get Price Quote

Turning Carbide Inserts

130 Per Piece

PCD & CBN INSERTS FOR TURNING, BORING AND MILLING

Get Price Quote

PCD & CBN INSERTS FOR TURNING, BORING AND MILLING Superabrasive Materials There are many different types of tip available in the market designed to cope with an array of workpiece materials but for simplicity these may be grouped as follows Polycrystalline Diamond (PCD). Cubic Boron Nitride (CBN). PCD PCD may be used for both roughing and finishing work, although it is usually most beneficial when tight tolerances or high surface finishes are required combined with the need for exceptionally long tool life. It is available in three grades of increasing crystal size and toughness but with an attendant decrease of edge quality. The finest grade is, therefore, only employed where superior surface finish is the main objective, the middle grade is the general purpose material giving long life with good component finishes; the coarse grade is used where maximum abrasive resistance is required and where finish is not critical. We will be pleased to offer advice on the selection of the best grade of PCD and cutting geometry for your particular application CBN If polycrystalline diamond has a major disadvantage, it is that being carbon based, it has an affinity to the free carbon found in most ferrous materials and is therefore generally unsuitable for machining steels and iron based materials. For this reason a range of products has been developed based on polycrystalline cubic boron nitride which have been demonstrated to be extremely cost effective especially with the harder ferrous materials (45-65 HR). Examples of materials that may be considered for machining with these inserts are listed below. Hardened Steels Chill Cast Iron Hardened Bearing and Tool Steels Stainless Steels Hard Facing Alloys which are Cobalt, Nickel and Iron based Grey Cast Iron CBN for Rough Machining: Different types of PCBN exist for the rough machining of the materials listed above which are usually selected on the basis of the required amount of stock removal. For roughing cuts in excess of 1mm depth the PCBN is usually supplied in the form of solid ISO tips for use in a clamp type tool holder, designed for use with negative top rake geometry. It is also usual to provide a strengthened cutting edge by means of a lapped or honed 'T' land. Where roughing cuts up to 1mm only are to be taken or when the applications require positive tool geometry, a brazable type of PCBN may be employed. In these cases the inserts are fabricated in a similar manner to diamond tips but usually with a polished 'T' land. CBN for Finishing: A specific form of CBN with reduced CBN content is supplied for use on fine finishing of hard ferrous materials. This material is capable, given the correct machining parameters, of producing turned finishes equal to those of ground components. The attendant cost savings found from switching from grinding to turning are often very dramatic. Again, the inserts are fabricated in a similar manner to those in PCD. Insert Shape: We follow the normal ISO convention for describing insert shape and geometry, for example an 12mm triangle may be designated as follows T P G B 12 02 02 T = Shape (triangular) P = Insert clearance angle (11°) G = Tolerance class (G) B= Type of insert, i.e., Hole and Chipbreakers 12 = Edge length (12mm) 02 = Insert thickness (2.38mm) 02 = Radius (0.2mm) CBN INSERTS PCD INSERTS PCD CBN MILLING INSERTS When ordering please specify PCD or CBNWe will be pleased to offer advice on the selection of the best grade of PCD and cutting geometry for your particular application.

CNC Machine Turning Insert

250 Per Piece

20 Piece (MOQ)

pcd insert

Get Price Quote

Carbide Inserts

Get Price Quote

We are offering carbide inserts ( carbide current pickups ) made from high quality raw material to give optimum performance. For electronic and all other makes.

PCBN BRAZED INSERTS

Get Price Quote

PCD Cutting Tools can be easily used to machine non-ferrous and non-metallic components. Diamond, in its purest form, is essentially carbon. Carbon is known to have an affinity towards iron at higher temperatures. These temperatures are quickly reached while machining at certain speeds. For this reason, diamond cannot be conveniently used for ferrous applications. PCD Tools are most frequently applied in the automobile Industry – comprising both heavy and light motor vehicles. Some of the materials that have been cost effectively machined with PCD Tools include: hypo and hypereutectic aluminum alloys, copper, bronze, babbit and abrasive plastic composites. Although machining ferrous material is not recommended for PCD tools, they can be successfully used for certain cast iron applications where high speed is not attainable and where Cubic Boron Nitride (CBN), which is conventionally recommended for cast iron machining, cannot be used. In such applications, it is seen that PCD wears more slowly at lower speeds. When a critical speed is reached, it starts wearing faster because at this speed, the heat generated while machining is sufficient to cause the chemical reaction between iron and carbon. However, at low speeds, PCD Tools have proved their worth on cast iron material by achieving much better results than conventional tools, maintaining high consistency and accuracy of the work piece for a very long time. The most significant application of PCD Cutting Tools, in this new generation of aluminium engine manufacturing, is to machine dissimilar materials such as aluminium engines with grey cast iron cylinder liners – either cast or pressed along with the aluminium – which have to be finish machined along with the aluminium blocks.

pcd insert

950 Per Piece

Pcd Inserts

Get Price Quote

We offer quality PCD Inserts that are used for cutting varied heat treated metals as well as metal workings, which are needed in Automotive industry. We are amongst the reliable Manufacturers, Suppliers and Exporters of the PCD Inserts, based in Chennai (Tamil Nadu). We offer these PCD Inserts at the market leading rates. Used For Cutting : Cast IronAluminumCopperHardened SteelBronze

Turning Insert

150 Per Piece

Pcd Inserts

Get Price Quote

Since the inception of our company, we have been instrumental in offering a wide range of the supreme quality of PCD Inserts to our esteemed customers. These inserts are used for turning, grooving, milling and boring of various metal and non-metal materials. Due to their rich features such as sturdy construction and corrosion resistance, the offered PCD inserts are highly appreciated among our customers. Owing to our extensive transportation facilities, we have been able to deliver these inserts in committed time-period to the customers' premises.

Carbide Threading Insert

300 Per Piece

PCBN Turning Insert

Get Price Quote

Carbide Inserts

Get Price Quote

We are the manufacturer and supplier of a comprehensive range of Carbide Inserts that is made of hard material having multiple cutting edges. Once a cutting edge is extremely worn, it can be indexed to another edge, or the insert can be replaced. We are the major distributors of a wide range of Carbide Insert that can be combined with high technology geometry designs on the inserts for general External Turning, Boring, Threading, Grooving, Face-Grooving and Parting Off Operations. Range Uncoated CarbideCVD Coated CarbidePVD Coated carbideTiAlN CoatedCermetCoated CermetPCBNDiamond Coated Carbide Used for External TurningBoringThreadingGroovingFace-GroovingParting Off Operations

Threaded Metal Insert

Get Price Quote

CVD Carbide Insert

270 Per Piece

10 Piece (MOQ)

grooving insert

200 Per Piece

SUMITOMO TURNING

Get Price Quote

Newly-developed "Brilliant Coat" provides a glossy finished surface like an uncoated grade with good wear resistance like that of a coated grade. A new dimension in Coated Cermet. Other Types are NEM-Type,AC6030M /AC6040M, GND-Type (Expansion), T1000A, NFB Type / NLB Type, GND Type Grooving System, AC405K/AC415K ACE-Coated Grades, AC805P/AC810P - ACE Coated Grade, AC420K ACE-Coated Grade, T1500A, BXBR Series, SSTE/SSTI Type, NSE/NSE-W Type.

carbide shim

Get Price Quote

carbide shim, Abrasive Grinding Wheel, carbide drill bit, CNC Chuck Jaw

Cutting Tool Inserts

Get Price Quote

Cutting Tool Inserts, Cermet Reamer, sc end mill cutter

pcd insert

Get Price Quote

pcd insert, ZCC Cutting Tools, Side Milling Insert, Face Milling Cutter

Pcd Inserts

Get Price Quote

Pcd Inserts, pcd shank tools, vitrified wheels, Resin, holders

Carbide Inserts

Get Price Quote

Carbide Inserts, hss scrap, hss thread roll, taps wire draw dies

Carbide Inserts

Get Price Quote

Carbide Inserts, hss metal scraps, Die, Cutters, Blades, bits

Pcd Inserts

Get Price Quote

20 Piece(s) (MOQ)

We are offering pcd inserts used for metal and stones.