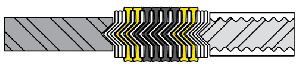

STYLE SJO SINGLE-JACKETED OVERLAP

In the single-jacketed overlap construction the maximum flange width is approximately 1/4". this type of gasket is used when total enclosure of the soft filler material is required and when the flange width makes it impractical to use a double-jacketed gasket.

...more

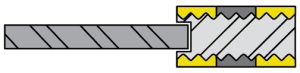

STYLE SJ SINGLE JACKETED GASKET

The majority of applications for single-jacketed gaskets are normally 1/4" or less in radial width. This type of gasket is widely used in air tool applications and engine applications where space is limited, gasket seating surfaces are narrow and relatively low compressive forces are available for seating the gasket.

...more

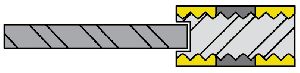

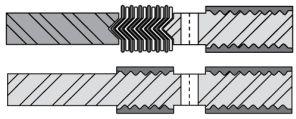

STYLE DJC DOUBLE JACKETED CORRUGATED GASKET

Double-jacketed gaskets are probably the most commonly used style of gaskets in heat exchanger applications. They are available in virtually any material that is commercially available in 26-gauge sheet. They are also extensively used in standard flanges where the service is not critical. Since most double-jacketed gaskets are custom made, there is virtually no limit to size, shape or configuration in which these gaskets can be made. In some cases nubbins are provided on heat exchanger designs to provide an intermediate seal. This nubbin is normally 1/64" high by 1/8" wide. Experience has indicated, however, that there is little advantage to this particular design. The primary seal is still dependent on the inner lap of the gasket doing the brute work and the secondary seal, when applicable, would be provided by the outer lap.

...more

STYLE DJ-DS DOUBLE-JACKETED DOUBLE-SHELL GASKET

The double-jacketed, double-shelled gasket is similar to the double-jacketed gasket except that instead of using a shell and a washer, two shells are used in the fabrication of the gasket. It has the advantage of a double lap at both the I.D. and the O.D. of the gasket, adding greater stability to the gasket. The construction will withstand higher compressive loads. Double-shell gaskets are normally restricted to use in high pressure applications.

...more

STYLE DJ DOUBLE JACKETED GASKET

Double-jacketed gaskets are probably the most commonly used style of gaskets in heat exchanger applications. They are available in virtually any material that is commercially available in 26-gauge sheet. They are also extensively used in standard flanges where the service is not critical. Since most double-jacketed gaskets are custom made, there is virtually no limit to size, shape or configuration in which these gaskets can be made. In some cases nubbins are provided on heat exchanger designs to provide an intermediate seal. This nubbin is normally 1/64" high by 1/8" wide. Experience has indicated, however, that there is little advantage to this particular design. The primary seal is still dependent on the inner lap of the gasket doing the brute work and the secondary seal, when applicable, would be provided by the outer lap.

...more

Spiral wound gaskets

Deltaone spiral wound gaskets are available in a variety of styles to suit the particular flange facing being utilized on the flanges. A winding is made of alternate plies of a metal wire and a soft non-metallic filler. The metal wire in the gasket is preformed into a "chevron" configuration, allowing superior resiliency and self-adjustment when compared to conventional gaskets. The Style W is just a sealing component (winding) only, which is normally used on tongue and groove joints, male and female facings and groove to flat flange facings.

...more

SPECIALTY SPIRAL WOUND GASKETS

DELTAONE Inhibitor gasket provides corrosion resistance in the most extreme conditions. It combines a HTG filler configuration with highest purity graphite, and a Kammpro inner ring laminated with soft PTFE material. The design of the Inhibitor gasket utilizes the Kammpro inner ring to provide the primary sealing interface. The inner ring material and its covering layer are inert in terms of corrosion through contact with dissimilar materials. This fire safe design incorporates the sealing integrity of highest purity graphite in conjunction with mica on the ID and OD, preventing the entrance of further corrosive conditions to the media.

...more

Rubber Sheets

DELTAONE offers complete range of rubber sheets, according to different requirement offers a variety of material rubber sheets, we produce all kinds of rubber products according to customer's demands. Manufacturer gaskets, etc. Rubber sheets reinforced with cloth or wire.

...more

Rubber Sheet

DELTAONE offers complete range of rubber sheets, according to different requirement offers a variety of material rubber sheets, we produce all kinds of rubber products according to customer\'s demands. Manufacturer gaskets, etc. Rubber sheets reinforced with cloth or wire. Types Rubber Seal Strip Rubber Sheet Rubber Sheet Reinforce with Cloth

...more

Rubber Gaskets

DELTAONE offers complete range of rubber gaskets, O-rings, and cork rubber gaskets. OEM service, we manufacture not only round gaskets, also manufacture nonstandard gaskets. eg. obround, with holes, and electric parts.

...more

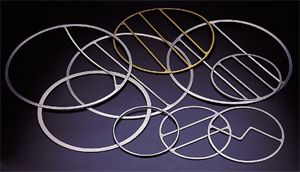

Ring Joint Gaskets

Deltaone manufactures and supplies a large variety of ring joint gaskets. The rtj standard size gaskets are manufactured in accordance to api-6a and asme b16.20 specifications.

...more

PTFE Packings

Deltaone manufacture complete range of ptfe packings. Teflon packing is used in high purity and corrosion resistance is required, it is widely used in food industries, the pharmaceutical industry. It can be braided with silicone rubber core to control leakage.

...more

PTFE Gaskets

PTFE has the best chemical corrosion resistance among known plastics. DELTAONE supply complete range of PTFE gaskets. Solid PTFE, Expanded PTFE Gaskets, and PTFE Envelope gaskets. DELTAONE supply the complete PTFE Envelope Gaskets, also provide PTFE Envelope only.

...more

PLAIN FLAT METAL GASKET

Flat metal gaskets are best suited for applications such as valve bonnets, ammonia fittings, heat exchangers, hydraulic presses, tongue-and-groove joints. They can be used when compressibility is not required to compensate for flange surface finish, warpage or misalignment and where sufficient clamping force is available to seat the particular metal selected. They must be sealed by the flow of the gasket metal into the imperfections on the gasket seating surfaces of the flange. This requires heavy compressive forces. The hardness of gasket metal must be less than the hardness of the flanges to prevent damage to the gasket seating surface of the flange.

...more

Oval And Octagonal Bx Ring Joint Gaskets

The hardness of the ring should always be less than the hardness of the flanges to prevent flange deformation. Dimensions for API ring joint gaskets and grooves are covered in ASME B16.20 and API6A DELTAONE stocks a wide range of sizes and materials ready for immediate shipment from R11 to R105. Stock materials include large variety of metals.

...more

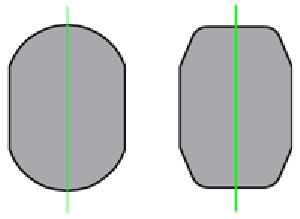

Oval And Octagonal Ring Joint Gaskets

API ring Joint gaskets come in two basic types, an oval cross section and an octagonal cross section. These basic shapes are used in pressures up to 10,000 DELTAONE. The dimensions are standardized and require specially grooved flanges. The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove. The newer flat bottom groove design will accept either the oval or the octagonal cross section. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or a edging action as the compressive forces are applied. The hardness of the ring should always be less than the hardness of the flanges to prevent flange deformation. Dimensions for API ring joint gaskets and grooves are covered in ASME B16.20 and API6A DELTAONE stocks a wide range of sizes and materials ready for immediate shipment from R11 to R105. Stock materials include large variety of metals.

...more

Ring Joint Gasket

DELTAONE manufactures and supplies a large variety of ring joint gaskets. The RTJ standard size gaskets are manufactured in accordance to API-6A and ASME B16.20 specifications.

...more

octagonal rtj gasket

The Kammprofile-Octagonal RTJ is sized to the standard octagonal API 6A or ASME B16.20 dimensions but with the addition of the Kammprofile design applied to the sealing areas and faced with oxidation inhibited flexible graphite. This design is ideal for applications where cracking or embitterment has been experienced in ring joint groove. It is available in a large variety of metal material and it can be fabricated as custom engineered designs.

...more

non-asbestos sheet

DELTAONE has the most advanced non-asbestos sheet production equipments. complete mastery of each index technology, the Non-asbestos Rubber Sheets comparable to the international famous non-asbestos sheets. Have the absolute price competitive advantage. Types Non-asbestos Beater Sheet Non-asbestos Beater Sheet Reinforced with Double Tanged Sheet Non-asbestos Sheet Oil Resisting Non-asbestos Sheet Reinforced Non-asbestos Beater Sheet

...more

Non-asbestos Gasket

DELTAONE supply complete range of non-asbestos gaskets. Different temperature different color and performance, with vulcanization processing, we manufacture oil-resisting non-asbestos gaskets. We constantly improve the technique level, at present had produced non-asbestos sheet match with KLINGER 4 series, and GARLOCK 3 series. Non-asbestos Gaskets is suitable for pipe flange, pump, valve joint.

...more

Metal Jacketed Gaskets

Metallic gaskets can come in different styles like; double jacket, single jacket, or solid metal. Soft compressible filler material can be flexible graphite, ptfe, or non-asbestos compressed sheet type. The design of a metal jacketed gasket also may require different shapes and the styles mentioned above can be made to a variety.

...more

Kammpro - HTG

Kammpro - HTG is recognized as a problem solver for heat exchangers, large vessels and equipment that experience high operating temperature. It utilizes a section of high performance mica/phyllosilicate that protects the graphite and shields it from contact of oxidizers. Kammpro HTG represents the best technology available in regards to torque retention and seal ability at elevated temperatures.

...more

Kammpro Dual Seal

Kammpro Dual Seal mates with leak detection devices incorporated into flanged assemblies used in critical applications, such as lethal service. This highly effective gasket has a primary seal followed towards the outer portion of the sealing area by a relief section with through holes, where the leak detection equipment is mounted. Past this relief section is a secondary sealing area that will maintain the integrity of the bolted joint should the primary seal be compromised and pressure differential is identified.

...more

Kammpro ACHE

Kammpro ACHE is specially designed to replace traditional solid metal "washer" type gaskets typically used in air cooled heat exchangers. The design takes advantage of the serrated profile with graphite facing to bite against the finish of the header plate and fill in the voids, creating a superior level of tightness. The Kammpro-ACHE has proven to be a very viable solution to emission concerns found where optimal conditions for metal-to-metal sealing are not realized.

...moreBe first to Rate

Rate ThisOpening Hours