Vibratory Table

The table mounted on mounting springs is vibrated by the unbalance vibro motor mounted at the bottom of the table�EFI� Vibratory tables offer a fast, efficient and economical method for compacting a wide variety of materials powdery, granular or flaky in boxes, drums or cartons. They are versatile and widely used for industrial applications to package, shock and fatigue test and for densifying refractory blocks, concrete products. They can also be used as shakeouts for some foundry flasks and in concrete block industries.

...more

Vibratory Motor

''EFI'' Vibratory Motor is specially designed Energy efficiency Motor, having Un balanced weight at both end of the shaft. Rotation of Un balanced weight at shaft end causes vibration. By changing their lead angle, various screening patterns are obtained to suit different application. Flange mounting and foot mounting Motors are available in various ranges

...more

vibrating equipment

Test Sieve Shaker

''EFI'' Test sieve shaker introduced to accurately reproduce the circular and tapping motion given testing sieves in hand-sieving. Uniform, mechanical action assuring dependable, comparable tests. The Ro-Tap has become the unquestioned standard of comparison in all laboratories.Sieve shaker designed to Back and forth lateral motion is combined with up and down and tilting motions to cause test material to travel in an orbit on the sieve surfaces. This forced travel assures full use of sieve mesh area without precise leveling of the tester. The Tester holds 6 full-height sieves and pan or 13 half-height sieves and pan.

...more

Suspension Magnet

�EFI� Suspension Magnets are designed for installation over conveyors where tramp iron contamination exists and needs to be removed for protection of subsequent processing machinery or providing cleaner product. Just suspend it over the conveyor or over the head pulley. When the magnet surface starts to fill up, swing the magnet away from the conveyor and cut the power (electromagnet) or use the convenient wiper arm (permanent magnet) to release the attracted metal. Suspension heights up to 10" to 12" are available. Manually cleaned magnets can be supplied with a stripper mechanism. No power consumption, virtually maintenance free. Suspension Magnet available is in permanent Magnet and Electro MagnetElectro Magnetic suspension Magnet consisting of aluminum or copper wound coils immersed in a transformer oil (for prevention of overheating or shorting) or air-cooled for extreme or dusty environments.

...more

Roller Conveyor

''EFI'' Horizontal roller conveyor is designed for Easy material transportation in Distribution centers, warehouses, assembly lines, shipping, palletizing systems, mail and parcel sorting centers, mail-order companies, etc.,Horizontal roller conveyor is suitable for handling Pallets, baskets, trays, cartons, boxes, parcels, etc.

...more

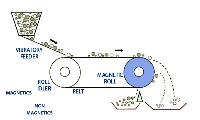

Roll Separator

“EFI” Magnetic Roll Separator Is used to remove fine iron contamination from the products such as Silica sand, quartz, magnesite, feldspar, dolomite, food products, chemicals, ceramics, etcMagnetic Separator consist of Hopper, Electro magnetic Feeder with Dimmer control, Roll Construction, Drive Motor, Adjustable Splitter Plates, Control PanelRare earth roll separator has a powerful rare earth magnetic roll, which also functions as a head pulley. As the product on the belt passes over the rare-earth magnetic roll, Ferrous particles stick to the belt while the non-ferrous particles fall freely off the belt into the non-magnetic chute due to centrifugal force. Adjustable splitters are provided to ensure an optimum magnetic non-magnetic split. Roll speed is variable and can be adjusted from 40 RPM to 400 RPM thereby enabling the aid of centrifugal force in separation of the magnetic and non-magnetic.

...more

Plate Magnet

�EFI� Permanent Plate Magnets are Suspended over your flow, chutes, ducts or located directly in the flow line, plate magnets produce a strong magnetic field separating tramp iron from your dry flow, maintaining product quality. It is used for excellent magnetic separation for removing small tramp iron such as nuts, bolts, etc. In certain cases, such as removing fine iron from powders, rare earth magnetic is required. These magnets are maintenance free, easily installed and not affected by wet conditions.

...more

pipeline magnet

�EFI� Pipeline Magnet is designed to attract of fine ferrous particles such as rust from fluids flows in pipeline. Material of construction is 304 or 316 stainless steel; the unit is simply connected to the existing pipeline via flanged or threaded ends. Magnetic Grill filters the flow and extracts the unwanted ferrous metal. Simple and easy access is possible using the quick release lid.

...more

Permanant Lifting Magmet

'EFI' Scrap Lifting Magnet can handle tones of scrap continuously throughout the day. It is used in metalworking “EFI” Permanent Lifting Magnets are suitable for all lifting operations in the modern workshop and for steel plates, sheets and blocks or steel rounds and tubes can be easily lifted. It is permanent magnetic technology that needs no electrical connection.

...more

Over Band Magnetic Separator

�EFI� Self-Cleaning Separators are designed for installation over conveyors where tramp iron contamination exists and needs to be removed for protection of subsequent processing machinery or providing cleaner product. The self-cleaning type uses a two-pulley design. Parallel self-cleaning magnets are mounted in line with the material flow, while transverse self-cleaning magnets remove the ferrous materials over the side of the conveyor.�EFI� Self-Cleaning Magnet is available in permanent Magnet and Electro Magnet.The Electromagnetic Over Band Magnetic Separator consist of a stationary tri-polar design magnet unit, with coils wound in aluminum wire or foil (copper available as an option) dependent on size, and insulated to Class �H� (or above) temperature specification to receive DC power supply. Magnets can be air or oil cooled, whichever is more suitable for the application. Oil cooled magnets are fitted with expansion tanks to ensure the coil is always immersed in oil.Self-Cleaning units, can be fitted across the conveyor, attracting the tramp iron and discharging to one side on the conveyor or in-line over the head pulley, discharging extracted iron forward of the normal trajectory. In certain applications, when site conditions dictate, an over band can be fitted in a diagonal position using the better features of both applications.

...more

Mobile Belt Conveyor

''EFI'' Mobile Belt Conveyor provides fast and efficient loading of trucks and trailers by delivering a steady flow of product to loading personnel. The fixed length belt conveyor is self propelled, steer-able and easily moved into and out of a parked trailer.Roller bed design reduces belt friction and provides greater capacity.

...more

Magnetic Head Pulleys

“EFI” Magnetic Pulley Provide contentious protection against tramp iron contamination of both large and fine iron particles. As product passes over the head pulley, non-ferrous material is discharged in a normal trajectory. Ferrous metal is attracted to the pulley and remains on the belt until the belt moves away from the pulley falling clear of the product stream. The separation is automatic and continuous. Widely used in RecyclingProcessing of aluminum, plastic, glass, wood, and other non-ferrous materials flows including Chemicals, food, grains, textile, ceramic and coal. Metal recoveryseparation of screws, nails, fasteners, blanks, wire, chain, tools and various ferrous objects from your product flows.ApplicationsTramp Metal Removal from Conveyor Systems Purification and Concentration of Ores, Chemicals and Granular Products FeaturesEfficient, cost-saving recovery of harmful tramp metal; Super-tough, trouble-free operation Exclusive continuous radial pole design grabs long rod-like tramp iron across the pulley face Develops especially powerful magnetic field at the center of the belt, where burden is deepest No DC power supply required All welded body and face construction — no bolts or screws to work looseEasy to install, permanent magnetic Pulley require no maintenanceFor higher level of protection, double and triple banked grids can be used. All grids are available with either ferrite or powerful rare earth magnets.

...more

Magnetic Floor Sweeper

�EFI� Magnetic floor sweepers are well built and incredibly strong with powerful magnetism. These sweepers perfect for clearing metal debris from walkways, garages and yards. Reduce the possibility of costly flat tires or personal injury, and decrease the time needed to clean up scattered ferrous metal material.

...more

Magnetic Equipment

Magnetic Chucks

�EFI� permanent magnetic chuck is widely used in the machine tool industry. It is Easy to install and to operate and it has the highest holding power .It is suitable for many milling applications and for general tool room grinding. FeaturesPowerful holding on entire chuck surface Solid construction top plate protects permanent magnetic pack from EDM fluidsFine pole divisions - for more uniform magnetic holding of small parts EDM operation does not affect by Magnetic.

...more

Magentic Grates In Housing

“EFI” Magnetic Grates in housing effectively remove ferrous fragments and fines from free-flowing material. Housings are constructed of 12 gauges mild or stainless steel.Inside the housing are two or more high intensity Magnetic Grates In Frames. Cleaning of the magnets is easily accomplished by removing the cover plate of the housing and sliding out each magnet assembly.

...more

Loading Unloading Conveyor

''EFI'' Loading, Unloading. conveyor is ideally suited for truck loading and unloading, distribution centers, packaging, portable assembly lines, shipping and receiving.

...more

Hump Magnet

�EFI� Magnetic Hump is an in-line magnet for extracting ferrous metals from pneumatic conveyor systems and chutes. The hump contains two powerful magnetic plates positioned at right angles to each other. Materials passing through the chute system are evenly distributed through the hump and across the magnets with little turbulence and no blockage. Any unwanted ferrous metals within these materials will be automatically extracted.

...more

Horizontal Vibrating Screen

''EFI'' Horizontal screen design is proven in hundreds of mining, ore and mineral applications. Custom-engineered designs may include side tensioned wire mesh screen decks. Multiple sizing decks (on a single unit), explosion-proof motors and Variable Frequency drives are important high-performance options. The wide variety of screening decks gives you improved performance for processing that follows size reduction mills or crushers.

Material : Metal

Application : Construction Wire Mesh, Fence Mesh

Feature : Corrosion Resistance, Easy To Fit

Warranty : 12 Months

...more

Gyratory Screen

''EFI'' Gyratory screen motion is the most effective method for screening. The heart of the Vibrating screen is its specially designed heavy-duty Energy efficiency Motor, having Un balanced weight at top & bottom end of the shaft. Rotation of Un balanced top weight causes vibration in Horizontal plane whereas the rotation of lower weight causes tilt & vibrations in vertical plane. By changing their lead angle, various spiral-screening patterns are obtained to suit different application.

...more

Grill Magnet

�EFI� Grate Magnets provide a high intensity high gradient magnetic field to remove ferrous metals from free-flowing materials. Grate Magnets are available in round, square, and rectangular shapes as per your requirement. It is used in or below hoppers, in closed chutes, floor openings, catch bins, and other locations to protect processing equipment and insure product purity. These grids encased totally in stainless steel.For higher level of protection, double and triple banked grids can be used. All grids are available with either ferrite or powerful rare earth magnets.

...more

Grate Magnets

Energy Finishing Machine

“EFI” Vibratory Energy finishing Machine provides a fast, consistent and economical way to finish large quantities of parts with minimal labor. Using the proper machine settings, chemical compounds, media, and time cycles, it is possible to obtain a uniform finish, load after load. They remove material from pockets and recesses and inside bores, which cannot be done in a tumbler, so they can be used for very delicate or intricate parts. With high speeds and a short stroke, they can also run large bulky parts without damage. Large wingspans and landing struts are routinely run in these systems. Machines are available in batch or continuous through-feed designs.

...moreBe first to Rate

Rate This