Rising Film Evaporator

Get Price Quote

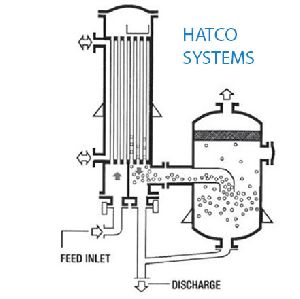

Rising Falling Film Evaporator Product Operation HATCO Falling Evaporator or Concentrator delivers high tube velocities which assures uniform product distribution and high coefficients of heat transfer. The rising falling film evaporator (RFC), or recirculating version, RRFC, works on uniform metered flow entering the bottom of the steamchest and rises through the first pass with rapidly increasing velocity. After leaving the first pass the flow of the vapor liquid mixture is reversed and directed downward through the second pass at extremely high velocity. The mixture then enters the separator where the vapor and liquid are separated. When not designed as a circulation unit, the rising falling film evaporator provides once through evaporation of heat sensitive materials, requiring minimum retention time. It is particularly adaptable to multiple effect systems but provides a lesser turn-down capability than the RRFC configuration. Rising Falling Film Evaporator Characteristics High tube velocity minimizes fouling. Able to achieve high concentrations at low temperatures. Risk of entrainment is greatly reduced since the major portion of the liquid passes directly out of steamchest rather than being re-entrained with vapor from the separator. System may be turned down without loss of efficiency or effectiveness. Holding time is a matter of seconds (RFC). Suitable for evaporation of a wide range of liquid concentrations. Low headroom requirement. Rising Falling Film Evaporator Product Applications Heat sensitive liquids requiring minimum process time. Pure or non-crystal forming liquids. Liquids having low to medium viscosities. Foamy liquids. Liquids containing fine suspended solids. Readily handles thixotropic materials. Rising Falling Film Evaporator Application Examples Ammonium- Nitrate Apple Juice Cane Sugar Syrup Caprolactam Corn Syrup Caustic Coffee Extracts Gelatin Glue Grape Juice Lemon Juice Orange Juice Pharmaceuticals, Heat-sensitive Pineapple Juice Tea Extracts

evaporator plant

Get Price Quote

Evaporator plant one of the most experienced manufacturers of falling film evaporators in India for dairy, food processing, textile and chemical industries. KWS has developed energy efficient evaporators indigenously.The plants designed and commissioned by us are doing very well. We are committed to do better service by providing tailor made solutions for your effluent treatment needs.

Best Deals from Evaporator

evaporator plant

Get Price Quote

concentration of high TDS effluent water, concentration of dilute liquids like food products,fruit juices etc., in different configurations like:-Multistage falling film type, Forced circulation, Natural circulation etc., in combination with thermal vapour recompresses (TVR) for steam economy.

wiped film evaporator

Get Price Quote

We manufacture and supply wiped film evaporators / agitated Thin Film Evaporator.

Industrial Evaporator

Get Price Quote

The industrial evaporator manufactured by us is customized according to client's requirements. The range comprises (i) waste water evaporator, (ii) waste oil evaporator and (iii) thermal evaporator. This range works on the technology of waste water recovery, which solves waste water as well as waste oil disposal issues. Thermal evaporators are offered in the evaporation capacities of 10-400 gallons per hour. The typical application consists of oily water coolants and lubricants, wash waters, rinse waters, high tds solutions, brackish waters, treated process water etc.

low temperature vacuum evaporators

Get Price Quote

low temperature vacuum evaporators, ccr air lift pumps, Diaphragm Pumps

steam cooking equipment

Get Price Quote

Our company manufactures and supplies of the world-class Kitchen Steam Cooking Equipments, which are made using an amalgamation of the excellent raw materials to ensure perfectness of Steam Cooking Equipments at customized prices. Steam Operated cooking equipments cooks dishes fast and perfectly which helps the food much more tastier. Idli cooking plant specially designed for making fast steaming hot idlies, made out of 18 swg stainless steel, mounted on SS stand with suitable electric cum gas.

mechanical evaporator

Get Price Quote

mechanical evaporator, Liquid Defoamer, Boiler Water Treatment Chemical

steam power plants

Get Price Quote

steam power plants, coal based power plant