Venturi Steam Desuperheater

Get Price Quote

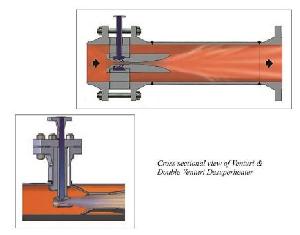

Jet Flow venturi desuperheaters consist of a Laval nozzle which utilises a part of the incoming steam flow to create a reduced pressure zone into which spray water is drawn and atomised by steam energy, and then exits in a short expanding throat which allows pressure recovery.The desuperheating performance remains constant at all loads from 100% or less, because of the atomising steam effect of the steam jet. The design is unique such that the spray water can be supplied at the same pressure as that of the steam pressure. High turndowns are possible depending uponinstallations.

chlorine evaporator

1,400,000 Per Unit

1 Unit (MOQ)

Best Deals from Evaporator

Steam Desuperheater

Get Price Quote

1 Piece (MOQ)

Superheated steam coolers are used to cool superheated steam in pipelines and to produce process steam at given temperatures. In the case of superheated steam coolers, the cooling water is preferably injected in the area of the smallest flow cross-section, with correspondingly highest vapor velocities. Due to the streamlined design, impermissible pressure losses are effectively prevented. Our steam boilers offer: Ring cooler with spring-loaded nozzles Venturi cooler with annular gap or nozzles (swirl atomization) Motion steam-assisted superheated steam coolers Multi-stage, regulated nozzle injection coolers

wiped film evaporator

500,000 Per Piece

1 Piece (MOQ)

Evaporators

Get Price Quote

Perfect Chloro System is a reputed manufactures Evaporators for Chlorine, Sulphur Dioxide and Ammonia. The capacity ranges are from 20 kgshr to 1000 kgs hr. Evaporators are classified into two categories depending on type of energy used for vaporizing, namely Electrically heated Evaporator, Steam heated Evaporator etc.

ZLD Heat Pump Evaporator

Get Price Quote

We are known as one of the reliable Manufacturers, Exporters and Suppliers of ZLD Heat Pump Evaporator in the southern part of India. Our expert team has perfectly designed and fabricated the ZLD Heat Pump Evaporator using high-grade metal components that have outstanding features such as corrosion resistant, withstand abrasion, longer shelf life and many more. We strictly follow the international quality standards in order to provide best Heat Evaporator to the buyer.

Multiple Effect Evaporator

Get Price Quote

In multiple-effect evaporators the heating medium in any subsequent effect is the vapor generated in the previous effect and thereby achieves a great steam economy. The purpose of TVR in a multiple effect evaporator is to compress the product vapor from an effect, to a higher temperature level by means of a steam ejector (TVR) to use it as the heating medium in that effect itself thereby reducing the prime steam consumption.

Electric Rotary Evaporator

Get Price Quote

Open Pan Evaporimeter

Get Price Quote

This Pan Evaporimeter is manufactured as per Is:5973 :1970. The Pan is manufactured from pure copper, duly tinned and epoxy pointed and tested for water leak proofness. The stilling well and thermometer clamps are manufactured from Brass. This is supported on wooden platform and covered with reinforced chickon. Measuring Jar is manufactured from transparent Acrylic. This Pan Evaporimeter is also available in galvanized Iron as per customer's requirement.

Rotary Vacuum Evaporator

24,000 - 24,500 Per Piece

Kettle Evaporator

200,000 Per Unit

Multi Effect Evaporators

Get Price Quote

We offer multi effect evaporators. evaporators are thermal concentrators for concentrating dilute liquid for increasing the solids content and for reducing volume of evaporating liquid, widely used for the concentration of liquids in the form of solutions, suspensions and emulsions.

wiped film evaporators

Get Price Quote

From Tamil Nadu, we are among the high-standing Manufacturers, Suppliers and Exporters of the Wiped Film Evaporators’ unbeaten range across the globe. Precisely constructed as per the industry laid standards, these Wiped Film Evaporators are most suitable for the heat sensitive materials. For client’s convenience, we offer the quality-assured Wiped Film Evaporators in the desired stipulations. Place order with us; medium or bulk & avail discounted offers. Specifications : Least residence time in heating one. Avoid over heating of the products. Inter cooler causes the immediate condensation of vapor hence no deterioration of distillate. Agitated Thin Film Evaporators High heat transfer.

Industrial Evaporator

Get Price Quote

The industrial evaporator manufactured by us is customized according to client's requirements. The range comprises (i) waste water evaporator, (ii) waste oil evaporator and (iii) thermal evaporator. This range works on the technology of waste water recovery, which solves waste water as well as waste oil disposal issues. Thermal evaporators are offered in the evaporation capacities of 10-400 gallons per hour. The typical application consists of oily water coolants and lubricants, wash waters, rinse waters, high tds solutions, brackish waters, treated process water etc.

Rising Film Evaporator

Get Price Quote

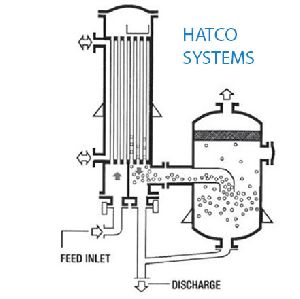

Rising Falling Film Evaporator Product Operation HATCO Falling Evaporator or Concentrator delivers high tube velocities which assures uniform product distribution and high coefficients of heat transfer. The rising falling film evaporator (RFC), or recirculating version, RRFC, works on uniform metered flow entering the bottom of the steamchest and rises through the first pass with rapidly increasing velocity. After leaving the first pass the flow of the vapor liquid mixture is reversed and directed downward through the second pass at extremely high velocity. The mixture then enters the separator where the vapor and liquid are separated. When not designed as a circulation unit, the rising falling film evaporator provides once through evaporation of heat sensitive materials, requiring minimum retention time. It is particularly adaptable to multiple effect systems but provides a lesser turn-down capability than the RRFC configuration. Rising Falling Film Evaporator Characteristics High tube velocity minimizes fouling. Able to achieve high concentrations at low temperatures. Risk of entrainment is greatly reduced since the major portion of the liquid passes directly out of steamchest rather than being re-entrained with vapor from the separator. System may be turned down without loss of efficiency or effectiveness. Holding time is a matter of seconds (RFC). Suitable for evaporation of a wide range of liquid concentrations. Low headroom requirement. Rising Falling Film Evaporator Product Applications Heat sensitive liquids requiring minimum process time. Pure or non-crystal forming liquids. Liquids having low to medium viscosities. Foamy liquids. Liquids containing fine suspended solids. Readily handles thixotropic materials. Rising Falling Film Evaporator Application Examples Ammonium- Nitrate Apple Juice Cane Sugar Syrup Caprolactam Corn Syrup Caustic Coffee Extracts Gelatin Glue Grape Juice Lemon Juice Orange Juice Pharmaceuticals, Heat-sensitive Pineapple Juice Tea Extracts

Rotary Evaporator

Get Price Quote

Finned Evaporators

Get Price Quote

The finned evaporators are of floor mounted Wallmounted Ceiling suspended type for frozen Storage, Blast Freezers, IQF Belt Freezers and chill rooms are designed for high efficiency.SS or galvanized steel tubes are used in the fabrication of the coil and are fitted with either GI fins or aluminium fins.These evaporators are manufactured either for Direct Expansion, Flooded system or Pump circulation. The highly efficient axial fan made out of cast aluminium ensure uniform airflow and also saves power.

Evaporators

Get Price Quote

Bioworks supplies, pre engineered multi effect evaporators to clients. Our in house R &D team has developed evaporators for handling concentrated streams of waste water from effluent treatment plants. We understand that every effluent is unique and the constituents of effluent differ from one to another. So we have sponsored lots of research on establishing the right ways to concentrate the waste stream. We have developed evaporators which can provide heat energy to the waste water by oil, electrical coils and steam. This evaporators use forced film, falling film, rising film and thin film evaporation techniques. Based on the quantity and nature of effluent we can provide the following type of evaporators Evaporators which use oil or flue gas heat exchange medium Vaccum Based multi stage evaporation units with steam as heat exchange medium We provide SCADA control system for operation and control of the evaporation units. We understand that proper monitoring of flow rates guarantees longer life, trouble free maintenance, easy performance evaluation of the evaporators. We also provide ancillary units like the chemical cleaning system, cooling water network and vaccum systems for the evaporators. Advantages of Bioworks made evaporators are as below Proven and reliable heat transfer rates Energy efficient units Operation friendly Easy maintenance Less land requirement Compact design

Mechanical Evaporators

Get Price Quote

Evaporator

Get Price Quote

We are the Leading manufacturer,Supplier and service Provider of Evaporators in Chennai, Tamil Nadu, India. Which is fabricated using quality raw material. The copper tubes sheets for condensers and liquid coolers is employed in the chillers such as industrial chillers, fabricated chillers, direct expansion type chillers etc., which ensure compact size thus occupy less space of plant room.

air conditioner evaporator

Get Price Quote

Indoor Evaporator Unit

68,000 Per Piece

1 Piece(s) (MOQ)

Indoor Evaporator Unit

36,000 Per Piece

forced circulation evaporator

Get Price Quote

Effluent Pan Evaporator

900,000 Per Piece

Rotary Evaporator

Get Price Quote

We are considered as one of the leading suppliers of Rotary Evaporator. The Rotary Evaporator supplied by us is procured from highly reliable sources who manufacture it using finest quality material and latest technology. The Rotary Evaporator offered by us is well known in the market for its unique features like reliability and superior performance. Moreover, we offer Rotary Evaporator as competitive prices. Features ReliableSuperior performanceDurableMade from high grade material

Rotary Evaporator

Get Price Quote

6 types of flasks ranging from 50㎖ to 3000㎖ - Rotary Evaporator is equipped with speed control,and R.P.M value is displayed in digital. - Digital Water bath covers ambient temperature up to 180°C - If water level at heating bath goes down,power will be cut off automatically by senser. - Speed control 20~280 R.P.M - Vertical condenser - Standard distillation - Continuous supply device for large capacity - Central connection - Dimensions(W×D×H) : 320×580×720mm - Power source : AC 220V 5060Hz2.5A - Heating Bath Power Wattage : 1000W 4.5A - Weight : 17kg

multiple effect evaporators

Get Price Quote

we manufacture industrial multiple effect evaporators. The evaporators are with 3 effects to 7 effects. Each evaporator system is complete with pre-heater, final condenser, feed & circulating pumps, cooling tower etc. our evaporators are designed for the best steam economy and are claiming film type to handle high salt concentrations. Vapour recompression is applied whereever required.they are widely used for reject management of ro plants.

Evaporators

Get Price Quote

Falling Film design high product quality Easy operation and automatic controls CIP cleaning so less chemical consumption Compact Design, Low building, continuous operation Suitable for heat sensitive products Suitable to work under vacuum Plants are with Thermal vapour recompressor

thin film evaporator

Get Price Quote

We manufacture and supply wiped film evaporators / agitated Thin Film Evaporator.