Glass Bottle Washing Machine

Get Price Quote

Capacities – From 60 to 200 Bottles per Minute Single End machine with Caustic main soak tank Built in Control Panel SS Spray pipes

Boiler Water Treatment Plant

Get Price Quote

Boiler Water Treatment Plant ABS – H900: OXYGEN SCAENGER, ABS – H800 : PH Booster, ABS – 124 : ANTISCALANT, Lubeck offers a broad range of specialty water treatment chemicals for water and waste water industry.

Best Deals from Filling Machine

Four Head Liquid Filling Machine

Get Price Quote

We are well known for manufacturing and supplying of wide variety of Four Head Liquid Filling Machine.

water cooled system

Get Price Quote

This type Air conditioner is large capacity unit so it's called Chiller. There are two types of chiller. One is Air cooled system another is Water cooled system. A liquid chilling system cools water, brine or other secondary coolant for air conditioning or refrigeration purposes. The most frequent liquid chilling application for air conditioning is water chilling, although both brine cooling for low temperature refrigeration and chilling of fluids in industrial Processes are also common. The basic components of a vapour compression liquid chilling system include a compressor, a liquid cooler, a condenser, a compressor drive, a liquid refrigerant or flow control. This type unit suitable for all purpose of commercial spaces.

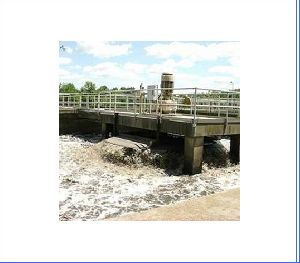

Sewage Treatment Plant

Get Price Quote

QWMS offers complete solution for sewage treatment and recycling of the treated water for gardening and toilet flushing. All sewage from residential./commercial complexes are treated for meeting the norms of Pollution Control Board. We offer the following processes for the treatment of sewage: ASP - Activated Sludge Process FBBR - Fluidised Bed Bio Reactor SAFF - Submerged Aerated Fixed Film MBR - Membrane Bio Rector We also supply custom built STP in MS FRP lined construction.

Drinking Water Treatment Plant

Get Price Quote

Our Drinking Water Treatment Plant is highly acknowledged for producing water in the purest form and meets all the requirement of Bureau of Indian Standard (BIS) IS 14543. Our Drinking Water Treatment Plant uses advanced “Reverse Osmosis” treatment for the removal of unwanted dissolved minerals, organics and microbial contaminations. We are a noteworthy Drinking Water Treatment Plant Supplier from Chennai, Tamil Nadu. We make available our Drinking Water Treatment Plant at highly affordable prices. Also, we ensure a quality tested product is delivered to our buyers. Additional information : This first stage purification is followed by disinfection system consisting of U.V. to ensure water of the highest quality is produced as the end point. Process : RO is mainly 3 Filterantion methods. They are as follow below, Sand Filteration Activated Carbon Filteration Ultra Violet Fileration

Grey Water Treatment Plant

150,000 - 190,000 Per Unit

1 Set (MOQ)

Domestic and commercial grey water treatment plant.

Water Distillation Plant

Get Price Quote

This is a fully automatic distilling plant capable of delivering distilled water continously. It is extremely compact and wail mounting type and hence does not occupy any floor space. it consists of a boiling chamber with semisphericallid with water gasketing. condensing column is located at the middle of the boiiing chamber extending to a length of about 24' below the boiling chamber. CAPACITY 2litres - 2000 Watts 2litres - 4000 Watts 2litres - 6000 Watts 2litres - 8000 Watts Specifications Pyrogen free distilled water Heater Load Support in 3 Kw Avg power capacity is 220/230 V A.C Uses Applied for regular using by: Steel Manufacturing unit Ferrous and Alloy Steel Foundries process Wire drawing Units Quality Control Test laboratory process used in Forging Units KSM laboratory glassware suppliers in chennai offers Thermocouples, Industrial oven, industrial furnaces, industrial heating elements, ceramic wares, electronic temperature controllers, industrial lab equipment at a superior quality. Our standards are best in the industry and we export our products to numerous players across the world. Our research and development continually take an effort to improve the equipment in terms of efficiency, durability, and reliability. The cost of the products are best in the industry and ensure that our customers are delighted with respect to that. Our service people offer the best for our customers during installation, maintenance, and support. Our customers across multiple continents are absolutely satisfied with our machinery and services.

Sewage Treatment Plant

Get Price Quote

Domestic wastewater is difficult to treat using conventional Activated Sludge Process, without having very large tanks and long hydraulic retention time to degrade the waste. Although Activated Sludge Process has been a proven alternative, in the present day scenario it is not possible to install the same due to constraint in space. (ASP will need almost 10 times higher space than what is currently available). With renewed focus on reduction of E-Coli in the wastewater, MBBR based sewage treatment plants with very nominal chlorination is the most successful and cost effective technology. It reduces the E-coli count from an inlet level of 106 � 107 MPN to less than 103 MPN at the outlet. .Advanced Technology of Fixed Film biological processes having large surface area for biomass to grow have been used in the past to reduce both the reactor volumes as well as retention times. Further developments in this field have led to development of fluid bed technology in which the fixed film media are made of small plastic materials which are freely moving and non-clogging type.The basic idea behind the Moving Bed Reactor development is to have a continuous operating non-clogging bio film reactor which requires (1) No back-washing,(2) Has low head loss and (3) High specific bio film surface area.This was achieved by having the biomass to grow on small carrier elements that move along with the water in the reactor. The movement within the reactor is generated by aeration in the aerobic reactor. These bio-film carriers are made of special grade plastic having density close to that of water. Apart from making the plant compact, the fluid bed reactor employing fixed film principle of the attached growth process makes the plant more user- friendly because it does not require sludge recycle i.e. synonymous with conventional ASP. The absence of sludge recycle relieves the operator from the enormous task of measurement and monitoring MLSS levels in the tank and adjusting recycle ratios continuously, due to fluctuating inlet COD loads.A number of treatment facilities where Moving Bed Reactor technology is used include small Sewage Treatment Plants, City Sewage Treatment Plants for population in Lakhs, industrial sewage treatment plant for food waste, paper waste and chemical waste etc.One more salient feature of this technology is that it produces much smaller quantity of sludge and what is more, this sludge requires no further treatment such as digestion, due to the fact that it produces digested sludge which does not smell like that in a conventional plant.

softner plants

Get Price Quote

Softeners are used to remove Hardness in the water. Pacific uses the proven Ion exchange process to remove the hardness in water. Our Softeners use 100 % corrosion resistant FRP tanks and User friendly Multiport Valve system. The Distribution systems and support media are designed for efficient & trouble free operations. Mild Steel and conventional Multi Port valve systems options are also available.Regeneration Required.

Industrial Ro Plant

Get Price Quote

This module is a very critical and important to all industrial reverse osmosis water planter’s safe operation. Improperly treated water can spell doom to highly expensive RO module and various other components of your system and would surely compromise with the quality of the output water.Our engineers design this module after performing the complete analysis of the feed water scenario of your site. This analysis determines the elements, hardness and contaminants present in the water and helps us determine the extent of pre conditioning required and configure the all important module of our industrial reverse osmosis water purifiers.

Water Treatment Plant

Get Price Quote

We are the leading manufacturer of Water Treatment Plant that is used in oil & gas industry, chemical industry, manufacturing industry, pharmaceutical industry, residential complexes and many more. It is the process of making water suitable to be discharged in rivers or ocean by treating toxic and harmful contaminants. Here, the process involves treating water for drinking purpose and for separating solid using physical method such as settling & filtration and chemical processes such as disinfection & coagulation.The plants we offer are built on international parameters and advanced technology, making it highly durable and efficient. The plant is completely corrosion free and does not require regular maintenance, making it cost effective solution. We at MJM are engaged in manufacturing and supplying a wide range of Water Treatment Plants, Sewage Treatment Plants, Effluent Treatment Plants and Packaged Water Treatment Plants. Apart from these we also offer package sewage treatment, combined sewage cum food waste treatment plants and combined sewage cum effluent treatment plants. We also offer effective turnkey solutions for these plants to our clients. Our entire range of plants and services are widely demanded in pharmaceutical industry, chemical manufacturing industry and food processing industry to name a few. Our tremendous success in this highly competitive sector is solely credited to the resources owned by us and our manpower being one of them. We have a team of professionals who have immense expertise in handling the sophisticated manufacturing process and later in providing effectual turnkey services to our clients. We have an excellent infrastructure to design, engineer, manufacture, carry out erection and commissioning the complete range of water treatment plant and systems to suit various requirements Raw Water Treatment Plants Drinking Water Treatment Plants Municipal Water Treatment Plants Packaged Drinking Water Treatment Plants Mineral Water Treatment Plants Spring Water Treatment Plants Sea Water Treatment Plants Turnkey Water Treatment Plants Process Water Treatment Plants Sewage Water Treatment Plants Effluent Water Treatment Plants Waste Water Treatment Plants Municipal Waste Water Treatment Plants Fully Automatic Water Treatment Plants

Bottle Filling Machine

Get Price Quote

Bag filling Machines

Get Price Quote

We are known to be one of the leading manufacturers and suppliers of this impeccable range of bag filling system or bag filling industrial machinery. For the purpose of maintaining this reputation, we engage in the utilization of high grade raw materials and modern machines, in accordance with the set industry norms and guidelines. in addition, the offered range is marked at the most reasonable rate possible. Features: easy operations longer service life superior performance specifications: system bag filling system scope of supply bag filling machine 3 mtr slat conveyor with bag closure (double stitch.) capacity 5 kg to 50 kg, (up to 100 kg) output 4-6 bags per minute dimension l-900 mm x w-900 mm x h-2700 mm product application free flow material resolution 10 gm filling accuracy up to 2e filling mechanism electro-pneumatic filling system load cell based, weigh metric coarse, medium and fine with auto in light correction filling mode coarse, medium and fine with auto in light correction digitizer advanced 8 bit micro controller power supply bagging machine-230 v ac, 50 hz., conveyor-440 v, 3-phase (2 hp). Air supply 5-6 bar. Air consumption approx 20 lpm accessories required air compressor (3 hp), cvt (optional)

Bag Filling Machines

Get Price Quote

Cement Clinker IRON ORE PETCOKE, Coal, Financial Services

Water Filtration Plant

Get Price Quote

Bottling Filling Machine

Get Price Quote

1 Pieces (MOQ)

We are the leading Bottle Filling Machine Manufacturers in Chennai. According to the needs and demands of our purchasers, we’re engaged in supplying a extensive range of Bottle Filling computer. Bottle water filling desktop is absolutely-automatic Bottling Line for Juices, Wines, liquids and so on. Bottled water filling computer, sometimes called packaged consuming water filling machine is generally used to p.C. Drinking water filling, mineral water filling, bottled water filling, spring water filling, juice filling, bottle filling and so on. Consuming water filling equipment can achieved first-rate bottled water packaging in aesthetic experience of bottle filling. Packaged ingesting water filling laptop and water packaging machines are accurate and high pace construction machines to p.C. Consuming water in pet bottles. Contact us for best Bottle Filling Machine Manufacturers in Chennai. We are among the foremost names of the industry, those present Bottle Filling Machines manufacturers that is provided at reasonable rates. These high performance machines are factory-made using progressive technology based machines. Due to the constant operation and longer functional life, these well-organized machines are highly desired. These purifying products eliminate impurities from the water making it clean to use. Our offered system is made by market leaders in accordance to preset international ethics utilizing finest components and innovative technology. In order to safeguard the quality of the products, these are stringently tested by our quality controllers on numerous parameters. Configuration: • 24-30 Bottles/Min • 40 Bottles/Min • 60 Bottles/Min • 120 Bottles/Min • 240 Bottles/Min Features: • Sturdy construction • Energy efficiency • Cost effectiveness

de mineralization plant

Get Price Quote

de mineralization plant, HIGH RECOVERY RO PLANT

Tea

Get Price Quote

Tea products only dealing in india. Quality maintain in each and every content. Our best service at all times

Adhesives

Get Price Quote

Adhesives, Holding Screwdrivers, air hoists