timer motor

a. 16 channels as a standard output. Higher or lower number of output channels may be provided on request. b. Sequence starts from 1st Channel Motor then it moves to 2nd Channel Motor and carried out up to the last channel in pre programmed Time duration between 1 to 9999 Sec for each channel.. c. Display: ½” high, 8 Nos of 7 segment Red LED display d. Output: 1 NO Relay contact per channel. All output contacts are rated for 3 Amp. @ 230Vac on resistive load, higher load capacity achieved by the way of activating Contactor by using the relay output available within the controller. e.. Operating Sequence: When the system is in the start mode the operating sequence of the output Load or motors is from first to last channel and if it is in the stop mode the operating sequence of the output Load or motors is from Last to First channel

...more

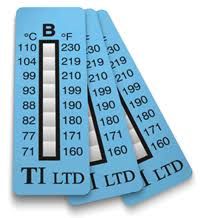

Temperature Indicator Labels

It is a Micro Controller based Indicator cum controller to indicate & control Temperature at the desired point. Front Panel programmable keypad arrangement for Data Entry to Set Temperature which generates necessary control output through Relays or Solid state relays. The required Alarm Indications in the front panel and control output are available on back Panel. This Unit designed to Indicate control temperature with RTD Thermocouple input as sensors. It supports RS232C 485 communication interfaces to take periodical printouts of Temperature parameters and for necessary Data Logging (on request).

...more

Solid state timers

The panel incorporated with all the necessary equipment, including motor rated MCCBs or MCBs, contactors starters with overloads, start stop buttons, run trip indication, speed indication, hand off auto switches, auxiliary contacts, relays, insulated transformer, means of isolation, wiring etc, Emergency stop push button allowing manual shutdown of the complete panel Complete shutdown of the panel upon receiving a signal from the Fire Alarm Panel interface

...more

Small End Bearing

In that system, oil is circulated through the system using an oil-pump, which may be driven directly from the crankshaft or indirectly from the camshaft or any auxiliary shaft. When the camshaft rotates, oil from the sump is drawn through the submerged strainer and pick-up pipe to the pump. The oil is then compressed and discharged through a drilling to the lubrication system. Control of the oil pressure is achieved by a pressure-relief valve situated on the output side of the pump. If the oil pressure becomes too high, the relief valve will open, bleeding any surplus oil back to the sump. From the oil-pump, all the oil flows through drillings in the crankcase to a cylindrical filter unit. The oil circulate around the filter bowl, forces its way through the center and flows out to the main oil gallery (the main oil passage). By various branch cross-drillings in the crankcase, oil is distributed to the crankshaft main-journal bearings and to the camshaft bearing.

...more

Sequence Timer

a. 16 channels as a standard output. Higher or lower number of output channels may be provided on request. b. Sequence starts from 1st Channel Motor then it moves to 2nd Channel Motor and carried out up to the last channel in pre programmed Time duration between 1 to 9999 Sec for each channel.. c. Display: ½” high, 8 Nos of 7 segment Red LED display d. Output: 1 NO Relay contact per channel. All output contacts are rated for 3 Amp. @ 230Vac on resistive load, higher load capacity achieved by the way of activating Contactor by using the relay output available within the controller. e.. Operating Sequence: When the system is in the start mode the operating sequence of the output Load or motors is from first to last channel and if it is in the stop mode the operating sequence of the output Load or motors is from Last to First channel

...more

Programmable Sequential Timer

Bag Filter Controller (BFC) is Solid State Sequential Timer, with a Digital Display. This is designed to control the cleaning cycle of On-Line Bag Filters with adjustable ON, OFF & Pause Timing. It is available in various models to suit different output requirements which are designed as per customer specification.

...more

programmable counter

Programmable On Time & off time anywhere in the ranger of 23hrs:59mins:59secs 5 feedback monitoring of Errors from 3limit switches & level & pressure occurrence of error & retrieval of errors against real time are logged in the memory for later retrieval and analysis Retreval of the data collected is essential for the maintenance dept to monitor & correct the errors for normal operation else which leads to downtime of the vehicle or machinery

...more

Multi Channel Temperature Scanner

Model Number : LAK06

Brand Name : FFI

Application : Industrial

...more

Lubrication Timer

An Automated Lubrication System also referred to as a Centralized Lubrication System delivers a controlled amount of lubricant (either grease or oil) to multiple, specific locations on a machine while the machine is operating at specific times from a central location. A typical automated system (grease or oil) includes a pump, controllertimer, lubricant supply line, metering devices and lubricant feed lines. Many of Standard Lubrication System Manufacturer’s pumps integrate the reservoir, controller and fault monitor capability in one unit for design simplicity and installation cost reduction.

...more

lift controller

Overload Controller is very useful for the protection of elevator controlling machines and inverter. It eliminates the Risk of over Loading inside the Lift thereby avoiding accidents by giving preventive control output to Main Control Unit.

...more

Length Measuring Machine

Type : Mini

Feeding Conveyor

Before starting conveyor system it is necessary to start first receiving conveyor and then start feeding conveyor i.e. operating logic is from downstream to upstream. For stopping of conveyor system the operation will be opposite. i.e. from upstream to downstream. So it is necessary if any conveyor is stopped in the system all the upstream conveyor should stop automatically. The existing system takes care of this logic. This is known as conveyor sequential operation.

...more

Cyclic Sequential Timer

Type : Digital

Cycle Timer

Bag Filter Controller (BFC) is Solid State Sequential Timer, with a Digital Display. This is designed to control the cleaning cycle of On-Line Bag Filters with adjustable ON, OFF & Pause Timing. It is available in various models to suit different output requirements which are designed as per customer specification.

...more

Conveyor Motor

Conveyors are seen on virtually all in the Coal Handling Plant (CHP). CHP are having number of conveyors. The control systems used for these conveyors are important for operating safe plant. Basically conveyors are dumb, but once equipped with proper control system they yield efficient and safe plant operation. Electronic intelligent conveyor control technology is useful for complex conveying tasks. But in CHP for control of conveyer system still use of simple onoff switches and some forms of speed switches are used.

...more

conveyor control systems

Before starting conveyor system it is necessary to start first receiving conveyor and then start feeding conveyor i.e. operating logic is from downstream to upstream. For stopping of conveyor system the operation will be opposite. i.e. from upstream to downstream. So it is necessary if any conveyor is stopped in the system all the upstream conveyor should stop automatically. The existing system takes care of this logic. This is known as conveyor sequential operation.

...more

Conveyor Control Panel

Type : Mini

Brand Name : FFI

Conveyor Belt Controller

Brand Name : FFI

Big End Bearing

A portion of power is called friction power is lost to overcome the resistance to relative motion of all the moving parts of the engine. This includes the friction between the piston rings, piston skirt, and cylinder wall; friction in the big end, crankshaft, and camshaft bearings. Friction in the valve mechanism, friction in the gears, or pulleys and belts, which drive the camshaft and engine accessories.

...more

Bearing Lubricators

A portion of power is called friction power is lost to overcome the resistance to relative motion of all the moving parts of the engine. This includes the friction between the piston rings, piston skirt, and cylinder wall; friction in the big end, crankshaft, and camshaft bearings. Friction in the valve mechanism, friction in the gears, or pulleys and belts, which drive the camshaft and engine accessories.

...moreBe first to Rate

Rate This