Uhmwpe Doctor Blade

From the early 1980s, paper machines became considerably faster and wider, and soft rolls were introduced. The soft roll covers were easily damaged by both metal and composite blades and a new blade material had to be found. The result of that search was high density polyethylene. Poly blades are best used on soft covers, as these blades also have the disadvantages of aquaplaning on wire rolls and trapping of abrasive particles which scratch the covers of felt rolls.Jaikay provides an ultra-high-molecular-weight polyethylene (UHMWPE) which has longer polymer strings than HDPE for extra durability. It is more stable than HDPE with a higher melting point. They are good blade for soft covers that are not too demanding. Additionally it features additional crosslinking alloyed with molybdenum disulphide which has long polymer strings, is dense and has high durability. The blade has more stable melting properties and will last at least twice as long as a regular polyethylene blade. It is a good option for soft press rolls, grooved or drilled rolls.

Brand Name : JAIKAY

...more

Phosphor Bronze Doctor Blade

phosphor bronze is an alloy of copper and tin. it conducts heat readily and retains a sharp cutting edge. its hardness (normally measured on the brinell scale, but converted to the rockwell c scale for comparison purposes) is about 16 rockwell c. bronze is generally regarded not as a sheet removal blade, but more as a conditioning blade for new or reground metal rolls. the exposed surface of new and reground rolls is usually quite porous and does not release the sheet cleanly. bronze is an excellent sheet release agent, and will readily transfer itself into the pores of a steel roll to give a smooth surface which will offer good paper making qualities.it is therefore normal practice to run bronze blades on new (or reground) rolls for 15 to 60 minutes at crawl speed to develop this conditioned surface. if the dryer cylinder was reground within the last year or so and a bronze blade was not used to seal the surface, it can still be done with a good result.

Brand Name : JAIKAY

...more

Glass Fiber Epoxy Doctor Blade

ypical glass composite blade thicknesses are 1.5, 2 and 3 mm. the blades are produced in many different colors and wearing properties vary significantly due to the use of different resin types. glass fiber blades have a high friction factor against most rolls. this can sometimes be a benefit because high friction provides an extra cleaning effect on the roll surface. experienced paper makers use glass fiber blades as the secondary blade on composite press rolls.this blade can be used for most doctoring positions. it grants superior doctoring for wire and felt rolls when used in combination with lubrication showers and oscillation. the blade is the preferred solution for dryer cylinders, which require good quality blades that can take the extreme heat. additionally, some fiber glass blades have abrasive particles added which increase the cleaning effect.

Brand Name : JAIKAY

...more

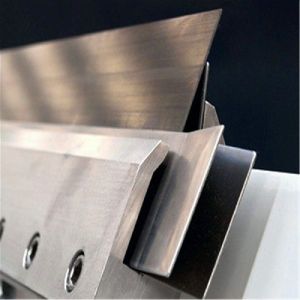

Carbon Steel Doctor Blade

Carbon Steel Doctor Blades aere some of the first doctor blade materials used, and are still found today in many applications where a tough blade is required to clean a roll surface or where high stiffness is needed to shed a sheet. steel blades are mainly used for intermediate dryer doctor applications.

Brand Name : JAIKAY

...more

Carbon Fiber Epoxy Doctor Blade

Common carbon fiber blade thicknesses are 1.5, 2 and 3 mm. Most blades are black in color. From blade to blade there is a big difference in the amount of carbon in the blade composition, and similarly to fiber glass blades there is a wide variety of resins used.The cost of carbon blades varies a lot from manufacturer to manufacturer, and even within a producer's product range. However the benefits can be huge comparing cost to runtime of the blade. Thus, it's very challenging and important for mills to determine which specific type and formulation of carbon fiber blade to use.Most mills require a doctor blade expert to assist with recommendations, trials and follow-ups. The main benefit of using a carbon blade is the very low friction coefficient. Stated another way, carbon blades transport heat from the blade edge very effectively. If it were possible to achieve 100% heat transfer, it would effectively be frictionless and the doctor would not wear at all. Water lubrication of the rolls is a powerful means of decreasing friction and reducing blade wear.

Brand Name : JAIKAY

...more

Bakelite Hylam Doctor Blade

hylam doctor blades are used where mechanical strength, wear resistance and resilience are more important than electrical insulation. typical applications of fabric laminates are gears, textiles shuttles, bearings, pickers, bushes and marine application. different grades offered to suit specific applications.

Brand Name : JAIKAY

...moreBe first to Rate

Rate ThisOpening Hours