Jigs and Fixtures

Get Price Quote

The most common jigs are drill and boring jigs. These tools are fundamentally the same. The difference lies in the size, type, and placement of the drill bushings. Boring jigs usually have larger bushings. These bushings may also have internal oil grooves to keep the boring bar lubricated. Often, boring jigs use more than one bushing to support the boring bar throughout the machining cycle.Uses: Jigs and fixtures are used to reduce the cost of production as there use elimination being out work and setting up of tools. To increase the production. To assure the high accuracy of the parts. To provide for interchangeability. To enables heavy and complex shaped parts to be machined by holding rigidly to a machine. To control quality control expenses. Less skilled labor. Saving labor. There use partially automates the machine tool. Improve the safety at work, thereby lowering the rate of accidents.

jigs fixtures

Get Price Quote

jigs fixtures, Automotive Turned Components, CNC Dies, Jigs

Best Deals from Jig Fixture

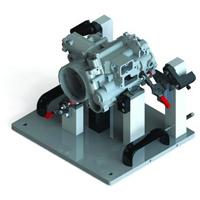

Jigs and Fixtures

Get Price Quote

Jigs and Fixtures, low density polyethylene film, mechanical sub assemblies

Drilling Fixture

Get Price Quote

Drilling Fixture, sheet metal fabrication service

jig fixture

Get Price Quote

Throttle Valve, throttle shaft, Jig and Fixture Design