Well Pad Manifold Skid

Each well pad manifold skid is designed to have seven slots that can be hooked-up to a maximum of seven wells (production, water injection and spare put together). This can be customized as per the requirement of the customer.

...more

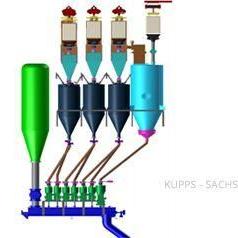

Weighing Feeders

Weighing Feeders and Volumetric Feeders are available with a number of different size metering augers – interchangeable on each of the individual model volumetric feeders – to cover a specific output feed range. Overall feed rates range from 0.0012 to 6600 cubic feet per hour, depending upon the selected volumetric feeder model and the size of its metering auger. In addition, and as standard, all Acrison volumetric feeders are equipped with variable speed drives that cover a wide operating range.

...more

solid handling systems

This division handles the supply of Material handling systems such as Gravimetric Feeders, Volumetric Feeders, Automatic & Manual Bag Unloading Stations, Big Bag Dischargers, Continuous Blenders and other Pneumatic Conveying components. We partner with Acrison and Rotex representing their products in the South East Asia region.

...more

Screening Separation Equipments

Their full line of best-in-class screening equipment, feeders, conveyors, and automated analyzers go above and beyond meeting the application requirements for agriculture, chemicals, fertilizer, food, minerals, plastics, recycling and more.

...more

Rental Chemical Injection skids

These are pneumatic skids and the pumps are Williams Equivalent these skids are ideal for offshore platforms or field trials where air gas is available.

...more

multimedia filters

Multimedia Filters offers a high-performance filtration and a longer operating cycle. The advance design allows operation at high flow rates of 12 to 20 gpm per square foot of filter area. The filter distribution system controls the velocity and hydraulic balance within the filter protecting the media during high rate operation. The filter flow rate covers a broad range of flow rates, and multiple units can be easily coupled to accommodate any larger flow requirements by forcing the collected solids deep into the media.

...more

liquid handling systems

This division handles the supply of Produced Water Filtration Packages, Well Pad Manifold Skids, Chemical Dosing Skids (rental skids are also available), LimePolymer Preparation & Dosing Skids and Chemical Management Services.

...more

Lime Polymer systems

The Limepolymer powder is unloaded into a holding hopper using a bulk bag discharger and hoist arrangement. The bulk bag discharger will be provided with an optional bag piercing mechanism. An operator can access the chute of the bag through the access window to set the bag.

...more

Walnut Shell Filtration

Walnut Shell Filtration is a method of filtering free oil and suspended solids in applications where the wax content is extremely high. This package is used to treat produced water, refinery waste water, ethylene plant quench water, copper concentrate decant and cooling water.

...more

Gas Floatation skids

The purpose of Induced Gas Floatation skids (IGF) are to effectively remove oil andor suspended solids from oily waste water. The aerator mechanisms circulates water influent, introduced from an upstream separation unit, which creates a froth layer several inches thick, of which the upper few inches contain the oil bubbles.

...more

Filtersafe BS single screen filters

Filtersafe BS-Series single multi screen filters are the perfect pre-treatment solution to protect the fine-filtration assets and equipment whether filtering Produced Water or Sea Water.

...more

Effluent Treatment Plant

The systems supplied by Kupps & Sachs are designed and engineered based on the customer’s requirements and matching the statutory norms. They consists of different modules such as: Surge Tanks DNF Unit

...more

DRA Injection Skids

DRA by nature due to its heavy molecular weight and high viscosity is one of the most difficult chemicals to handle and requires ancillary equipment other than the dosing pump and piping.The skid is manufactured and packaged in a container (porta cabin) suitable for remote installation with limited operational intervention

...more

Control Panels

We provide a suitable solution for: Exd installations; ExeExI; purged panels & climate controlled portable control rooms. We have in‑house strengths to supply control systems integrating Solid Handling Systems and Liquid Handling Systems, all under one roof.

...more

Chemical Injection Skids

The chemical injection rate for compressor system number one is a maximum of 4 LPH at a maximum 8KgCm2. Two mechanically actuated diaphragm pumps are supplied as one duty and the other as stand-by. The dosing pump will take the suction from the respective feed tank.

...more

Chemical Injection Skids

Chemicals are supplied in liquid form and these chemicals are then transferred to the feed tank with the tank inlet fitted with a check valve and isolation valve to prevent the back-flow of the holdup chemical. Tanks have a level transmitter for continuous local and remote level monitoring and an alarm is given off once the chemical is too low or high and the dosing pump gets tripped once the tank level reaches low-low level, this is to avoid pump damage.

...more

Big Bag Dischargers UNITS

The Bulk Bag Discharger can be provided for handling either bulk bags or 25 kg bags or else a combo unit can be supplied which is designed to handle both bulk bags and the 25 Kg bags. The Bulk Bag Unloader provides a clean, efficient and effective means for discharging a wide assortment of dry solid materials contained within various size and type of bulk bags. It is especially effective in the discharge of non-free flowing materials. Designed to empty the entire contents of a bulk bag, typically into a metering mechanism, the ruggedly constructed bulk bag unloader will handle bags weighing up to two tons; the bags can be disposable, reusable or lined.

...more

Big Bag Dischargers

Chemical Dosing Skid

volumetric feeders

Weighing Feeders and Volumetric Feeders are available with a number of different size metering augers � interchangeable on each of the individual model volumetric feeders � to cover a specific output feed range. Overall feed rates range from 0.0012 to 6600 cubic feet per hour, depending upon the selected volumetric feeder model and the size of its metering auger. In addition, and as standard, all Acrison volumetric feeders are equipped with variable speed drives that cover a wide operating range.

...more