Wobbling Feeder

The wobbling feeder is a piece of equipment that combines feeding and screening, which is especially designed to continuously feed the heavy duty crusher. After clay and fine materials are screened out by the feeder, the load on the crusher is greatly decreased and crusher clogging reduced, thus increasing productivity, cutting energy consumption and reducing

...more

Vertical Roller Mills

Vertical roller mills are large grinding machines developed, designed and manufactured by Sinoma-tec Sinoma-tec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizes. Sinoma-tec vertical mills are widely used in industries such as cement, power generation, metallurgy, chemical and coal processing A Vertical mill consists mainly of motor, planetary gearbox, grinding table, grinding rollers, rocker arms, mill stand, mill housing, separator, water spray unit, pressure device, lubrication system, and rocker arm sealing.

...more

Toothed Roller Crusher

The crusher is suitable for crushing materials of low compressive strength and viscous materials, such as silt stone, shale, clay and frozen soil

...more

Single Unit Pulse jet Bag Filter

The single unit pulse jet bag filter de-dusts by the air of individual dedusting points It features linear air distribution, online de-dusting, cages with venturis, good de-dusting effects, modular design, simple structure, flexible assembly into multi-module units and good adaptability to dust load requirements

...more

Single Stage Hammer Crusher

The crusher is suitable for crushing medium hardness limestone and similar minerals.It features simple structure. Large feeding size.High crushing ratio and low energy consumption.Suitable for crushing minerals mixed with viscous earth, such as clay.

...more

Secondary Hammer Crusher

Used for secondary crushing of minerals High crushing ratio and high productivity Wear parts with long service life Low energy consumption per unit output and easy operation

...more

Rotary Kiln

Rotary kilns are used to produce materials, such as cement clinker, alumina, magnesia, ceramsite and lime under high temperature. The TPD range from 1000 to 14000 and the Dia vary from 3Mtrs to 6.2 Mtrs.

...more

Roller Press

The roller press is a highly efficient and energy-saving choice for grinding hard and medium hard materials. It is widely used in manufacturing andor processing of raw meal, cement, slag non-ferrous metals and iron ore. When upgrading the capacity of ball mill systems, it is the best choice of equipment. A roller press can be used as a pre-grinding system or in a combined grinding system with ball mills. Independently, it can also operate as a finish grinding system.

...more

Preheater System

After extensive research and data from the existing preheater systems, and at the same time considering the characteristics of raw materials and fuels available in cement plants, the latest generation of Sinoma-tec preheater system represents a comprehensive upgrade from earlier generations. This updated system features optimized process and environmental performance. While operating with low system resistance and energy consumption, it will further contribute to reduced investment in construction investment. Also the level of emission of harmful components in the exhaust gas, such as NOx, and Sox has been significantly improved. The new design allows to make use of the full value of resources. It also permits to utilize all kinds of wastes as alternative fuels or additives, which allows the plant to develop towards an ecological, greener production. With environmental and ecological concerns, this new system is not only more cost effective but also more environmentally friendly.

...more

Plenum Pulse Jet Bag Filter

The plenum pulse jet bag filter is another type of bag filter de-dusting by air pulses Utilizing air pulses from the plenum, it features fewer purge valves, offline de-dusting, good de-dusting effects, solid structure, and low initial investment It is suitable for directly treating dust-laden, flammable and explosive fumes

...more

pan conveyor

The conveyor is used for horizontal and inclined transport of high temperature bulk and granulated material. It is used in a variety of industries, such as building materials, metallurgy, coal, chemical processing and power generation.

...more

Jaw crusher

The jaw crusher is suitable for crushing ores or minerals whose compressive strength is below 300 Mpa.

...more

Impact Crusher

The crusher is suitable for crushing minerals of medium hardness, such as limestone. features simple structure, large feeding size, high crushing ratio and low energy consumption. The particle size of its products meets the requirements of concrete manufacturing for aggregates with flakey shapes.

...more

Highly Efficient Pulse Jet Bag Filter

The pulse jet bag filter is used for collecting and removing solid particles from exhaust gas Its applications include: collecting dust from the high temperature gas exiting clinker cooler, preheater, raw mill and dryer; collecting dust as the finished product of grinding systems forcement, slag and coal; exhaust gas de-dusting in industries such as metallurgy, power generation, chemical processing, machine manufacturing or residential steam boilers Clean air dust content at the outlet can be reduced to as low as 2 mgm3

...more

Pulse Jet Bag Filters

The large pulse jet bag filters developed by Sinoma-tec have been used in various ESP conversion projects (ESP to BF conversion technology). A series of bag filters have been designed to cater to production lines of different capacities. By the end of 2012, Sinoma-tec has successfully completed about 100 ESP to BF conversion projects for cooler and preheater de-dusting in cement production lines. These conversion projects feature effective operation, compliance with emission requirements, as well as low investment, system resistance, air leakage and energy consumption.

...more

Dryer Hammer Crusher

The dryer hammer crusher combines drying and crushing in one machine, specifically designed for low-abrasive and soft materials of high moisture.

...more

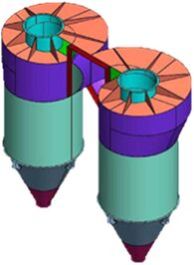

CYCLONE

Owing to our well-equipped manufacturing unit, we have been able to manufacture and supply a superior quality range of Industrial Cyclones. The high-grade raw material is procured from the reliable vendors of the market to manufacture these cyclones in compliance with the set industry standards. All the dust particles are driven towards the envelop surface where they are screwed down with the help of tangential inlet, which allows a flow rotating movement to the gas. The concept of the LV Cyclone is a design with the inlet pulled as far away from the outlet tube as possible. The roof spirals downwards to avoid re-introducing circulated gases into the new gases entering the cyclone. The unique body design further ensures an effective separation of gas and material. As a result a high cycolne efficiency combined with a low cyclone pressure loss is achieved. The LV Cyclone is applied for raw mills, Various cement mills and preheaters.

...more

clinker cooler

Coolers are used with rotary kilns to rapidly cool hot clinker or other materials exiting the kiln. The latest generation clinker cooler of Sinoma-tec has the characteristics of “Three high and one low”, i.e. high cooling efficiency, High transmission efficiency and high operation rate, super low wear. It has realized online maintenance and overhaul, and ensured the high operation rate of the burning system. Sinoma-tec has developed and manufactured coolers to meet the capacity requirements of 1000 td ~ 12, 000 td production lines.

...more

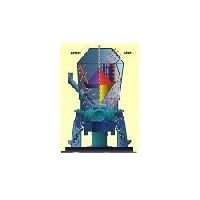

LV Classifiers

We are one of the leading manufacturer and supplier of LV Classifiers. These classifiers are manufactured using high-grade raw material, which is procured from the reliable vendors of the market. In addition to this, to ensure the international standards and norms, these classifiers are tested on various well-defined parameters.LV Classifier and its unique separation concept The principle of classification is same for all the classifier but what makes LV classifier unique is its three phase classification compared to single phase classification in modern classifier.

Country of Origin : India

Type : Air Classifiers

Certification : CE Certified

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg

Color : Brown

Voltage : 110V

Condition : New

...more

Chain Bucket Elevator

The bucket elevators are mainly used for vertical transportation of bulk materials. They are categorized into three types: Low Speed, Medium Speed and High Speed. Low Speed: Suitable for elevating granulated material or powder at a low speed. Medium Speed: Suitable for elevating limestone and clinker at a medium to low speed.

...more

Bucket Elevator

Elevating altitude: up to 150 meters. Elevating capacity: up to 1300 th Compact alignment of buckets, which ensures continuous material reception and discharge. High reliability and lower operation cost compared with chain elevators

...more

Belt Conveyor

Belt of belt conveyor moves according to the friction drive principles. The conveyor is applicable to transport packing density less than 1.67tm3 and easy to dig, powder, granular, small block low-mill materials and bags materials such as coal, gravel, sand, cement, fertilizer, food and so on. Belt conveyor uses in the ambient temperature -20°C to +40°C range and the sent material temperature is less than 60 °C . The conveyer length and assemble form can be sure according to the customer’s requirements. Technicians of Henan Sinoma Cement Equipment Co., Ltd introduce the belt conveyor can be divided as: general canvas core conveyor belt, high-strength steel cord belt conveyor, flame-type belt conveyor, two-speed dual belt conveyor, reversible mobile belt conveyor and so on.

...more

Ball Mill

LNV Technology is known for its reliable products, which are developed with design standards and latest Technology. It is also known for fast and customized solution for product and process. The mill is of two compartments, gravity flow mill consisting of a shell with end covers, supported on white metal lined bearings. Inner surface of mill shell is lined with wear resistant Hi-chrome material liners having a particular profile which provides required trajectories to balls inside mill to have maximum grinding efficiency. The ball trajectory and size of ball defines the mix of grinding operations that is impact (crushing) and attrition (grinding), and thereby will help in controlling the granulometry of mill product.

...more

Air Slides

Our organization holds specialization in manufacturing and supplying a wide assortment of Air Slides. Manufactured using mild steel, these slides are a simple device, which have the structure like box. Throughout the length inside, the aeration cloth is fixed, which functions with the help of a suitable capacity fan. In addition to this, the slides offered by us are used to handle powdered material. For handling cement and grits, these Air slides are recommended in cement plants at mill discharge points.

...more

Retrofitting Services

Our organization is counted among the firms engaged in providing Retrofitting Services. These services reduce the power consumption and enhance the production capacity. By providing better residue control on the product, these services provide better particle size distribution of the product. The services offered by us are rendered in compliance with the exact requirements of the customers using high-grade raw material and advance machines.

...more

Engineering Services

Our organization is counted among the firms engaged in providing Retrofitting Services. These services reduce the power consumption and enhance the production capacity. By providing better residue control on the product, these services provide better particle size distribution of the product. The services offered by us are rendered in compliance with the exact requirements of the customers using high-grade raw material and advance machines.a layout of a cement plant is a logical and practical arrangement of the various sections and stages of the plant in a process sequence starting with receipt of raw materials and ending with final dispatch of product and the processes that would help in production, in an efficient and effective manner, using optimum inputs interms of space, raw materials, fuel, energy and man power, along with minimum disposal of waste

...more

Plant Audit Services

Be first to Rate

Rate This