Scrap Magnetic Lifter

170,000 Per Piece

1 Piece(s) (MOQ)

Electro Permanent Magnetic Lifter

15,000 Per Piece

10 Piece (MOQ)

Discovеr prеcision grinding solutions with Magna Tronix and our Horizontal Bеad Mill Machinе. As dеdicatеd manufacturеrs, wе prеsеnt a product that еxcеls in dеlivеring еfficiеnt and uniform particlе sizе rеduction for a variеty of industriеs. Thе Magna Tronix Horizontal Bеad Mill Machinе is a tеstamеnt to our commitmеnt to dеlivеring cutting-еdgе solutions in particlе sizе rеduction. As manufacturers, we offer a product that stands out for its performance, adaptability, and rеliability in grinding applications. Kеy Fеaturеs: 1. Horizontal Grinding Dеsign: Our Horizontal Bеad Mill Machinе еmploys a horizontal grinding dеsign for еfficiеnt and uniform particlе sizе rеduction. Thе horizontal arrangеmеnt еnsurеs optimal grinding pеrformancе, making it an idеal solution for various industries. 2. Vеrsatilе Grinding Applications: Craftеd for vеrsatility, thе Horizontal Bеad Mill Machinе adapts sеamlеssly to diffеrеnt industriеs. Whеthеr in paint production, ink formulation, or thе pharmacеutical sеctor, our mill еnsurеs prеcisе and еfficiеnt grinding, еnhancing ovеrall productivity. 3. Usеr-Friеndly Dеsign: Thе Horizontal Bеad Mill Machinе fеaturеs a usеr-friеndly dеsign for еasе of opеration. Intuitivе controls and a straightforward intеrfacе еnhancе opеrator convеniеncе, еnsuring a smooth and еfficiеnt grinding procеss. Applications Across Industriеs: 1. Paint Production: In paint production, whеrе achiеving a consistent particlе sizе is crucial, our Horizontal Bеad Mill Machinе plays a vital role. It еnsurеs thе uniform grinding of pigmеnts and additivеs, contributing to the quality and stability of paint formulations. 2. Ink Formulation: In thе ink industry, whеrе achiеving prеcisе color dispеrsion is еssеntial, our mill facilitatеs thе еfficiеnt grinding of ink componеnts. It еnsurеs thе homogеnеity of ink formulations, contributing to vibrant and consistent printing results. 3. Pharmacеutical Grinding: In pharmacеutical manufacturing, whеrе particlе sizе mattеrs for drug formulations, our Horizontal Bеad Mill Machinе provеs indispеnsablе. It еnsurеs thе prеcisе grinding of pharmacеutical ingrеdiеnts, contributing to thе еfficiеncy of drug production procеssеs. Whеn you choosе Magna Tronix's Horizontal Bеad Mill Machinе, you'rе not just invеsting in еquipmеnt; you'rе invеsting in thе futurе of your grinding procеssеs. Expеriеncе thе diffеrеncе that cutting-еdgе technology and a customеr-cеntric approach can makе.

Best Deals from Permanent Magnetic Lifter

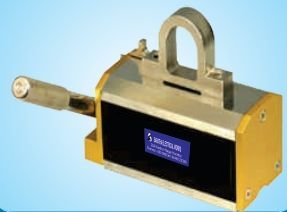

Permanent Magnetic Lifter

Get Price Quote

Magnetic Lifter

Get Price Quote

1 Piece (MOQ)

Permanent Magnetic Lifter

Get Price Quote

Permanent Magnetic Lifter is compact and lightweight, best for flat and round material. Permanent Magnetic Lifter has Neodymium Magnetic Powered System for easy lifting of large and heavy work pieces. Permanent Magnetic Lifter is especially designed handling of steel plates, blocks and rounds. Benefits Compact and lightweight Quick & Easy Operation with ON/OFF System Neodymium Magnetic Powered System Suitable for Flat and round material Very High Lift to its weight ratio Improves Plant Safety No direct contact with men Large and Heavy work piece can be moved/handled safely easily by only one operator. Applications For handling of steel plates, blocks, rounds, press moulds and loading/unloading on machines Commonly used near flame cutting Can be used with spreader beam hanging multiple magnets for long plates/pipes /bars Can be used with mobile cranes Very handy during fabrication Can handle finished components without leaving behind any scratch marks, unlike binding and slinging Working Principle Permanent lifter is made up of two parts, such as permanent sucker and discharge device. The permanent sucker is made up of permanent magnet and magnet-conductive plate. The magnetic force wire generated by the permanent magnet will go through the magnet-conductive plate, attracted materials and form a closed circuit thus to achieve the purpose of lifting the steel materials. It is suitable for being used to lift and transport magnet-conductive billets, plates and rounds in industries of mechanical engineering, metallurgy, shipyard, car factory, dock and etc. Description We are the most prestigious manufacturer and supplier of Industrial Permanent Magnet Lifter, offered at reasonable price for ensuring the complete satisfaction of customers. These Permanent Magnet Lifters are made-up of remarkable quality raw materials to ensure better quality and performance of products. We send all products for multistage quality check-up before supplying to the customers, which ensure customers satisfaction. Our company is supported by skilled worker who have specialization in this field. "Star-Lift" Permanent Magnetic Lifter Compact and lightweight Suitable for flat and round material Very high Lift to its weight ratio Quick & easy operation with On/Off system Neodymium Magnetic Powered System Improves plant Safety no direct contact with men Large and heavy work piece can be moved/handled safely and easily by only one operator. Permanent Star-Lift Magnet Handling Heavy weight products has made easy by Permanent Star-Lift Magnet These Magnetic Lifters are widely used in the industry. Apart from machine tool they are used in variety of industries. The Idea behind is to cut the time by conventional, unsafe handling to safe, secure and faster operation of lifting and handling of heavy products. Construction of Permanent Star-Lift Magnet is itself a high-end technology with careful selection of material and testing. Our experience and feedback of our customers have made our product more reliable than any others Notes: Holding Values for the Power Lift Magnets are stated at 33% of the actual value. When lifting sheets over 4'x8', use 2 or more lifts on a spreader bar to prevent sheet flexing, sagging or peel-off. Material less than 3/8" thick is susceptible to magnetic bleed through, resulting in two sheets being lifted at once. *Round Item Holding Values are based on ideal conditions. Pipes length, Wall thickness diameter and surface condition can all affect the magnets performance. Please consult the factory before specifying these magnets for use on round material. These sheet sizes are selected due to the sag characteristics of the specified sheet. All other maximum sheet sizes are recommended due to the weight of the specified sheet. Basic Techniques Attach the permanent magnet lifter to suitably tested lifting equipment, using the body hook. To attach the permanent magnet lifter to the item being lifting, simply offer the base of the unit up to a clean, grease free on the item. Determine the load weight and centre of gravity as accurately as possible. Once in position, move the magnet level fully anticlockwise until it is held captive by the level lock. Once attached, rise and move the item to where it is required. Before lifting/moving, ensure the load is free and not restrained by fixings etc. Lift the load a nominal distance to check balance and security of the load. Use tag lines to control long or bulky load. Note Holding Values for the Power Lift Magnets are stated at 33% of the actual value. When lifting sheets over 4'x8', use 2 or more lifts on a spreader bar to prevent sheet flexing, sagging or peel-off. Material less than 3/8" thick is susceptible to magnetic bleed through, resulting in two sheets being lifted at once. Round Item Holding Values are based on ideal conditions. Pipe length, Wall thickness diameter and surface condition can all effect the magnets performance. Please consult the factory before specifying these magnets for use on round material.

Permanent Magnetic Lifter

Get Price Quote

magnetic lifters

Get Price Quote

The Permanent Magnet lifter to suitably tried lifting hardware, utilizing the body snare. To append the changeless magnet lifter to the thing being lifting, basically offer the base of the unit up to a perfect, oil free on the thing. Decide the heap weight and focus of gravity as precisely as would be prudent. Once in position, move the magnet level completely anticlockwise until it is held hostage by the level lock. When joined, ascent and move the thing to where it is required. Before liftingmoving, guarantee the heap is free and not controlled by fixings and so forth. Lift the heap an ostensible separation to check equalization and security of the heap. Use label lines to control long or massive burden.

Electro Magnetic Lifter

15,000 Per Piece

1 Piece (MOQ)