Telescopic Dustless Loading Spout

The retractable dustless loading spout is designed to load dusty, free-flowing bulk materials into a variety of containers and vehicles like opened/closed trucks, railcars, barge, ships, stockpiles with virtually no dust emissions. It is a self-contained unit comprised of a series of stackable cones for product column control, a flexible outer sleeve for dust containment, and a cable-winch system for spout retraction. The spouts are available with a wide variety of control features for any desired level of automation. The spout can be provided with positioner’s integral dust collector, Weighing and control automation. The DLS comes in a wide range of sizes capable of handling from 200 CFM of material to in excess of 1,200 CFM of material. Merit spouts have a number of features that are unique and give the user added benefits. Construction Features TDLS made up of stackable cones covered by weather proof sleeve materials. Cone material selected based on the bulk material to be loaded. Effective - complete dust control system, unmatched by competitive dust control systems. Dustless operation is achieved by its venture design Horizontal travel is through positioner as an option Fugitive dust containment. Three cables winching for additional stability sizing and detailing based on capacity and operational frequency. The loading spout is available with wide variety of control features for required lengths and capacity. Controls Geared rotary limit switch to control both extreme positions. Ultrasonic level sensor used for automatic spout rises pile height increases. Remote control is provided as an option. Application Merit’s customized product design of this dustless loading spout is very much applicable in loading of cement, fly ash, bagasse, etc.

...more

telescopic chutes

We are the main supplier of this product.

Size : Standard

Type : Telescopic

Material : Aluminum, Mild Steel

Certification : ISI Certified

Application : Industrial Use

Feature : Easy To Operate, Good Quality, Rust Proof

Finishing : Polished

Warranty : 1 Year

...more

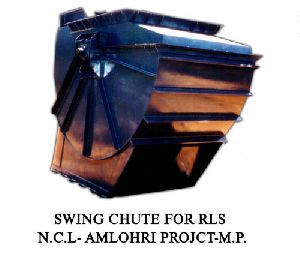

Swing Chute loading device

Swing chute is a bulk loading device with as high as a loading rate of 13500 TPH. Used for loading of bulk materials like coal, iron ore, pellets, lignite etc. The swing chute can be used for loading of moving wagons/ railcar, trucks etc. and the chute can be positioned at different heights for different wagons.

...more

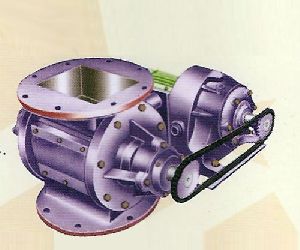

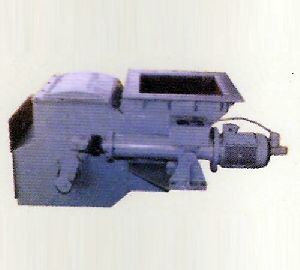

Rotary Air Lock Valve

This kind of valve is mainly used to create sealing effect between Discharge Hopper and the equipment below the valve. Blades provided with rotor seal off the bottom of hopper preventing air form leaking while continuously extracting material from the hopper to pneumatic conveying systems or atmosphere. It is also used for feeding and metering of bulk material such as granulates and powder from the heart of the system. Merit Rotary valves offer a wide choice and range for various applications including Two Way Rotary Diverter. Features Continuous operation is achieved by its rugged design Blades are adjustable. Different pressure differentials are achieved by adjustable Blade tips. Different capacity is available to meet user requirement. Operation Electrical.

...more

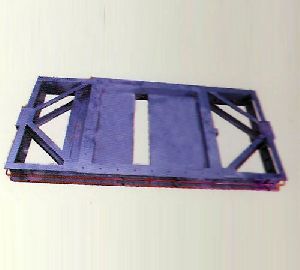

Rolling Slide Gate

A rolling slide gate is a heavy duty gate with lot of operational advantages. Limit switches, activators and position indicators can be combined to interface with your control logic. If modulation is required, it can be slaved from a microprocessor or other control systems. Unique seal arrangement that optimizes both sealing and cleaning of the blade.

...more

Ramp Valve

The ramp valve is a multi-purpose, tightly sealing shut-off device for bulk solids or slurries. Its unique performance achieved by better sealing arrangement, caused by wedging action of Ramp Bar between the top surface of the slide plate and the inner throat. Merit’s ramp valve incorporates: Superior sealing due to wedging action. Versatility on high temperature and /or high pressure applications. Operation Manual / Pneumatic / Electrical.

...more

Pinion Gate

These gates are ideal for low headroom use. They come with hand wheel of varying dimensions as well as gear reducers for added ease of opening. They are most suited for the flow control of and bulk dry material from fly ash to coal, cement to uranium oxide etc. Operation Manual / Electrical

...more

Non Jamming Rolling Blade Diverters

The curved blade design of this diverter gates offers many advantages over the conventional single blade diverter. During closing, blade will cut through standing column of material. Hence there is no jamming or back-up problem found in this type of diverting gates. Gate is ideal for diverting coarser dry materials that have a tendency to wedge between the blades and side wall and plug a chute. The rolling blade design eliminates jamming by having only thin edge of blade sweeping the side wall. Special action of the blade provides excellent sealing capability.

...more

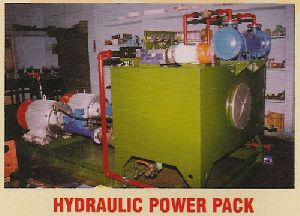

Hydraulic Rapid System

Merit is an innovative and leading engineering company focused into design and manufacturing of pre-weigh type Rapid loading systems. These systems are designed to meet custom specified requirements and ensure the highest standards of performance and reliability.

...more

FLOW CONTROL GATE

Flow control gate is a curved bladed non jamming type design used for loading of bulk material like coal, coke, lignite, iron ore etc. The flow control gate can be varied from full open to full close and the feedback can be given to PLC for further control. Gate can be designed for a capacity upto 18000TPH .Actuation could be either hydraulic/ electrical. Smooth opening/closing ensures the precise control of the bulk material flow.

...more

electronic system

PLC control coupled with SCADA system is used to control the entire loading system is designed by merit. Batch weighing system is the utilization of a weigh bin to precisely measure the amount of material transferred in to the weigh bin via a precision weighment. The system provides a complete printed record including car number, tare weight, net weight, time and date of loading and additional information if any.

...more

Double Flapper Valve

this valve is typically used in high temperature and abrasive application. dfv prevents both pressure loss and heat and heat-transfer between one compartment and atmosphere by its special sealing arrangement. it handles cement, ash, clinker, stringy material etc. the heavy-duty merit makes double flapper valve has: easy access for maintenance. few moving part. flat contact seating surfaces are hard-faced and ground. superior wear characteristics on abrasive materials. high temperature capability. operation pneumatic / electrical / counter weight.

...more

Coal Valve

This heavy-duty valve with special features has been specially designed for use with coal. The result is a reliable, economical valve that will operate easily with dry dusty coal or wet, sticky coal in all weather conditions. Advantages of the coal valve are: Completely enclosed. Self-cleaning rack and pinion gear design. Drive and rollers protected from flow of the coal. Operation Manual / Electrical.

...more

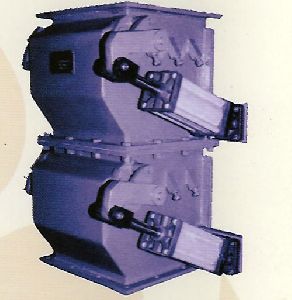

Clamshell Gate

These are welded steel simplex/ duplex gates suitable for handling Stone, Coal, Clinker, Sand, Gravel, Crushed rock, or other similar materials. Advantage is fast, smooth and even opening with minimum force. Features Include Single blade or double blade designs. Single or Duel cylinder. Operation Hydraulic / Pneumatic / Electrical.

...more

Belt Feeder Gate

This gate is highly applicable where controlled and smooth flow with least impact is desirable. In this gate discharge opening is aligned longitudinally with the center-line of the belt conveyor, which produces and improved material profile on the belt. The belt feeder performs as a volumetric feed rate control device, which can adjust t varying material flow properties. The belt feeder gate has few moving parts, consumes minimum energy.

...more

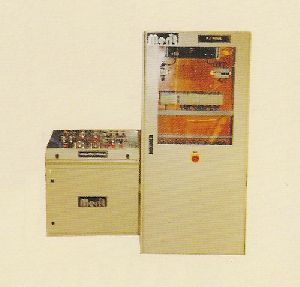

Batch Weighing Control system

Batch weighing is the utilization of a weigh bin to precisely measure the amount of material put into a pre-weigh hopper via a precision weighment. The system provides a complete printed record including car number, tare weight, net weight, time and date of loading. Additional information can be printed if required. CONTROL SYSTEM Programmable logic controller coupled with a color graphics operator interface panel enable the operator to control the entire system. PLC & CONTROL DESK Merit provides specially designed PLC to monitor and control all the mechanical equipment through a set of input output module. PLC connected with supervisory and batching electronics to generate sequence control, data logging, printing data display and dynamic mimic display. COMPUTER SYSTEM The use of a high speed, state of the art computer, utilizing Microsoft’s Windows platform provides user friendly screens with powerful pull down menus and icons for easy operation. MIS FACILITIES User specified loading reports for records and billing purpose. MIS reports like Shift/Day/Weekly/month wise reports available.

...more

Three Way Diverters Valves

Be first to Rate

Rate ThisOpening Hours