Rubber Metal Gasket

Get Price Quote

All our products including Rubber Gaskets are in compliance to world standrads like KTW , W270,DGVW, WRAS ETC are standardized and are only manufactured with SYNTHETIC Rubber SUCH AS EPDM, NBR, SILICON,FKM,FFKM having hardness of DIN 53505, Shore A to make them resistant to water, seawater, pond water, closed loop water up to 90°C and also against alkalines up to some extend like 50% NaOH at 50o. For effective functioning at even high temperature range of approx. +80°C and for short-term up to +90°C, HoriakiIndia Pvt. Ltd. Rubber Metal Gaskets Water Lines, Rubber Metal Gasket DGVW etc. have the density DIN 53479, g/cm3 1.384.Based on our own test facilities Horiaki India Pvt. Ltd. manufactured rubber metal gaskets are certified resistant even against natural lighting, weather and ozone. Limited only by the natural properties of vulcanized rubber our rubber metal Gaskets are not resistant against fuel, mineral oils, acids and gases. Chemical resistance : Vulcanisates of natural rubber (NR) are resistant against: water, seawater, pond water, closed loop water up to 90°C Partly against alkalines, 50% NaOH at 50°C Sufficient resistant against natural lighting, weather and ozone Vulcanisates of natural rubber (NR) are not resistant against:fuel, mineral oils, acids and gases Application field : The application of NR-vulcanisates is possible where natural media have to be sealed. Temperatures higher than 90°C have to be avoided. Function and durability : The performance and life of Horiaki gaskets depend in large measure on proper storage and fitting, factors beyond the manufactor’s control.We can, however, vouch for the excellent quality of our products.With this in mind, please also observe our installation instructions. Rubber Metal Gaskets KTW The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring Sizes at the measurement table: d1 = Inner diameter d2 = Outer diameter s = Thickness Vulcanised rubber gasket, cross section in lens form, rounded edges. Inside vulcanised steel ring, therefore good reception of the bolt force. Outer diameter of the gaskets fits to the inner bolt circuit for self centering. Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40. DN 15 up to DN 2000 Rubber Metal Gaskets W270 The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring. Sizes at the measurement table: d1 = Inner diameter d2 = Outer diameter s = Thickness Vulcanised rubber gasket, cross section in lens form, rounded edges. Inside vulcanised steel ring, therefore good reception of the bolt force. Outer diameter of the gaskets fits to the inner bolt circuit for self centering. Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40. DN 15 TO 2000 Rubber Metal Gaskets- DGVW The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring. Sizes at the measurement table: d1 = Inner diameter d2 = Outer diameter s = Thickness Vulcanised rubber gasket, cross section in lens form, rounded edges. Inside vulcanised steel ring, therefore good reception of the bolt force. Outer diameter of the gaskets fits to the inner bolt circuit for self centering. Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40. DN 15 TO 2000 Rubber Metal Gaskets water lines The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring. Sizes at the measurement table: d1 = Inner diameter d2 = Outer diameter s = Thickness Vulcanised rubber gasket, cross section in lens form, rounded edges. Inside vulcanised steel ring, therefore good reception of the bolt force. Outer diameter of the gaskets fits to the inner bolt circuit for self centering. Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40. DN 15 TO 2000 Rubber-Metal-Gaskets – Safe sealing of gases and liquids Safe sealing of water, gas, air, acids, alkalis and hydrocarbons with low sealing forces at temperatures up to 200°C, depending on the elastomer type. Rubber-metal-gaskets are used where safe sealing of conventional up to special industrial media such as gases and liquids are required under usual installation conditions like temperatures, pressures and forces Suitable for all flange materials A flange connection has to be always treated as a coherent system, because the sealing functions is determined by the interaction of individual elements including flanges, gaskets and screws HORIAKI HRS Rubber gasket, lenticular shape, rounded edges. Steel ring, chemically treated, no possibility to separate the elastomers from the steel core. Suitable for flanges made of metal. Self-centering with the same flange DN and PN appropriate tightening torques Self-limiting compression surface Rigid gasket, easy to install Soft surface in order to seal slightly damaged flange surfaces Blow-off proof n Materials :NR, NBR, EPDM, CSM, FKM Dimensions according to EN 1514-1 depending on DN: PN 6 to PN 40 DN 15 up to DN 2000 HORIAKI HRS/S Rubber gasket, Lenticular shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rounded edges. The spear tip provides higher safety at lowest contact pressures.. Suitable for installation between flanges made of metal and plastic Self-centering with the same flange DN and PN Minimum tightening torques and smaller than HRS (see diagram below) Materials of HORIAKI HRS/S : NBR, EPDM, FKM, EPDM fire resistant Dimensions according to EN 1514-1 depending on DN: PN 10 to PN 40 DN 15 up to DN 1000 HORIAKI HRS/TS Rubber gasket, flat shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rectangular outside diameter. The spear tip provides higher safety at lowest contact pressures. suitable for flanges made of plastics such as PE, PP, GRP, PVC Self-centering with the same flange DN and SDR Reduced dead space Tight, also at low tightening torques Materials of HORIAKI HRS/TS: NBR, EPDM, FKM Dimensions according to the valid European standards for plastic tubes made of PE, PP, PVC, PVDF and GRP (mainly SDR 11,17 and 33) Materials of rubber-metal-gaskets NR Field of application: Water ,Circuit water ,Diluted alkalis up to max. 50% and max. 80°C Temperature: approx. +80°C, short-term up to +90°C Colour: Black Certificates: EN 681 -1 WC Class 70 Applications: NR vulcanized materials can be used where noncritical media have to be sealed. Higher temperatures than 90°C have to be avoided NBR Field of application: Gas Media containing hydrocarbon Waste water Water Color: black Temperature: from -15°C to +100°C Certificates: DVGW Certificate acc. to EN 682 GBL, EN 681-1 WG Class 70, EN 682 GBL Class 70 ,TA-Luft (German Clean Air Act) Applications of NBR vulcanized materials result from the listed characteristics, such as resistance against aliphatic carbohydrates, mineral oils, greases fuels Epdm Field of application: Drinking water, Waste water Process water Color: black Temperature: from -40°C to +110°C, short-term up to +130°C Certification:EN 681 -1 WAL/WCL Class 70 ,Elastomer Guideline (new KTW,) DVGW W270 ACS, WRAS (BS6920), FDA Certificate, TA-Luft (German Clean Air Act) Applications of EPDM vulcanized materials mainly result from the good resistance to chemicals. Furthermore, the EPDM quality has a good resistance against ozone and aging. Csm Application in case of alkalis and acids in the chemical industry Color: black Temperature: from -10°C to +80°C Certification: TA-Luft (German Clean Air Act) Applications of CSM vulcanized materials can be found in the chemical industry, in chemical cleaning etc. FKM(VITON) Application in case of higher temperatures (Viton is the brand name of DuPont ® for FKM) in the chemical industry COLOR: brown Temperature: from -20°C to +200°C Certification: TA-Luft (German Clean Air Act) Due to the good resistance against acids and alkalis, the main use is in the area of chemistry and their users. HORIAKI HRS-ptfelon Rubber-Metal-Gasket with PTFE jacket Gasket material: EPDM ethylene-propylene-rubber developed in accordance with the main European drinking water requirements. Very good properties of resistance against ozon and ageing. Material for jacket: Virginal PTFE up to DN 900, modified PTFE from DN 1000 Dimensions: HRS: DN 15 up to DN 2000 acc. to EN 1514-1. HRS/TS: DN 16 up to DN 400 SDR 11 and 17 Application field: Safe sealing of pipe systems where aggresive fluids are flowing. Specially suitable for coated flanges and plastic flanges in PE, PP, PVC and GRP. PTFE is quite against all fluid resistant INTERNATIONAL MARKET EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA UNITED STATES(USA), CANADA, MEXICO RUSSIA AUSTRALIA AND NEW ZEALAND ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc Indian Market Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur

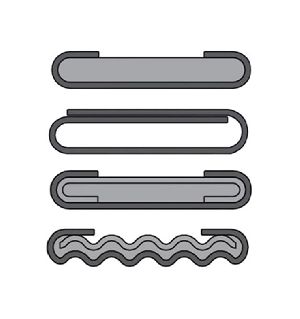

Metal Jacketed Gaskets

Get Price Quote

Metal Jacketed Gaskets and Corrugated gaskets can be manufactured to suit a range of chemical environments by the selection of a suitable alloy jacket or core. We offer the following materials: Double Jacketed Gaskets Exchanger Gaskets [Double Jacketed Gaskets] Double Jacketed Corrugated Gasket Corrugated Metal Gaskets [CMG] Single Jacketed

Best Deals from Metallic Gaskets

Corrugated Metal Graphite Gasket

Get Price Quote

The Corrugated Metal Graphite Gasket that we provide is highly appreciated for its high quality including features like strength and durability. This Corrugated Metal Graphite Gasket is manufactured with a corrugated metal as core with flexible graphite sheet adhered to both gasket faces. This type of Corrugated Metal Graphite Gasket makes an excellent product for both standard flange gaskets and heat exchanger type gaskets where there is low bolt load or high available gasket stresses. Highlights : High seal abilityConformity where low bolt load is availableMaintains high bolt loads, upon re-tightening, in heat exchanger applicationsHeavy gauge corrugated insert for supportChoice of insert metals

Metal Gasket

Get Price Quote

we are offering lead gasket, aluminium gasket, copper gasket, ss gasket, brass gasket, serrated metal gasket, mild steel gasket etc.

Metal Serrated Gasket

Get Price Quote

Available in a wide range of sizes of 10-1000 mm, the Metal Serrated Gaskets are used for sealing purposes. The Grooved Metal Serrated Gaskets are better alternatives to the jacketed heat exchanger gaskets. Being a major Manufacturer, Exporter & Supplier of Metal Serrated Gaskets, we make use of the best grade raw materials like CS, SS and graphite for production.

corrugated metal gaskets

Get Price Quote

An excellent choice for 150 and 300 class ASME flanges where available bolt loading is minimal. The substrate geometry promotes recovery and resilience through thermal cycles and extended service life. CMGs can be direct replacements for spiral wound gaskets and can eliminate inward buckling issues while creating a seal at moderate flange stresses. Available in a wide range of substrate alloys and covering layer options, CMG style flange gaskets can be utilized to solve many common flange problems. CMG substrate geometries are engineered to achieve maximum recovery characteristics. A specific pitch, core thickness and wall angle is engineered to maximize the seal's ability to overcome relaxation through joint relaxation, pressure and thermal cycles.

metal jacketed gasket

Get Price Quote

Metal jacketed gasket Aiflon Metal Jacketed gasket(MJG)is made from graphite, ceramic, non-asbestos etc. Filler covered with thin metal jacket, such as stainless teel, carbon steel, copper etc., special used in sealing spots of heat exchanger, pressure vessel etc. This gaskets highly resistance against blow-out, suitable for high assembly stress 6200DJ Double Jacketed plain gasket 6200DC. Double Jacketed corrugated gasket 6200H DJG for Heat Exchanger 6200S DJG with special shape Filler material Jacket meterial Temperature Pressure. Graphite, Asbestos Non-asbestos Ceramic PTFE Carbon steel 300 6.4 Copper 400 6.4 3.4 316 530 6.4

Spiral Wound Metallic Gaskets

Get Price Quote

Special Spring like Metal strips are wound with an Asbestos Filler by a special process to assure a leak proof seal. The sealing is done by the Asbestos Filler and the metal strip provides the spring.

Metal Reinforced Gasket

Get Price Quote

A laminated gasket with a metal core, covered using soft conformable sealing materials on each face of the core is a Metal Reinforced Gasket falling in the range of up to pressure class 300. The solid metal core prevents gasket blowout by providing high strength and rigidity while the soft core accounts for exceptional gasket sealing. Metal reinforced gasket manufactured at Goodrich Gasket Pvt Ltd finds its application in chemical and petroleum industries being a high temperature gasket, offering corrosion resistance and high integral jointing.

PLAIN FLAT METAL GASKET

Get Price Quote

Flat metal gaskets are best suited for applications such as valve bonnets, ammonia fittings, heat exchangers, hydraulic presses, tongue-and-groove joints. They can be used when compressibility is not required to compensate for flange surface finish, warpage or misalignment and where sufficient clamping force is available to seat the particular metal selected. They must be sealed by the flow of the gasket metal into the imperfections on the gasket seating surfaces of the flange. This requires heavy compressive forces. The hardness of gasket metal must be less than the hardness of the flanges to prevent damage to the gasket seating surface of the flange.

Solid Metal Gaskets

Get Price Quote

We offer Solid Metal Gaskets. SOLID METAL GASKETS Solid metal gaskets are used in applications where temperatures and pressures rule out the use of traditional gasket materials. In general, gasket compression loads need to be high to deform the gasket, and the metal used for the gasket should be softer than the metal in the mating surfaces. MATERIAL OF CONSTRUCTION Carbon Steel, Stainless Steel 304,304L, 316,316L,316Ti,321,347, Monel® 400, Inconel® 600,625,800, Incoloy 800, 825, Nickel 200, Titanium, Hastelloy, Copper. SPECIFICATION As per Customer Requirement. SIZE As per Customer Requirement. SHEATHING MATERIAL Graphite, PTFE etc. We are also capable of producing several millions pieces of punched and pressed metal components and are keen to add new products to our range.

corrugated metal gaskets

Get Price Quote

Thin sheet metal gaskets with pressed corrugations – usually concentric around the bore.Surface configuration with corrugations enables the gasket to adapt to rough or irregular flange surfaces without undue compressive load.Provides efficient seal under varying conditions of temperature and pressure.Can be custom made in any suitable metal.Usually formed in 0.25mm brass sheet, but almost any malleable material will be considered.In material to suit the application, and to any practical shape, size and quantity.

Metal Gaskets

Get Price Quote

Solid metal gasket is manufactured from solid metal /sheets. These are utilized in male/female joints, valve covers and NH3 fittings etc We manufacture following range of solid metal gaskets; SS 304 Flat gaskets SS 316 Flat gaskets SS 321 Flat gaskets CS Flat gaskets Aluminum flat gaskets etc Monel

Metallic Gaskets

Get Price Quote

Metallic gaskets are used as heat exchanger gaskets and also in pumps, valves etc despite of their limited recovery and resilience property. Gasket sealing is effective under high bolt loads, smooth flange surface finish and flange flatness.

Semi Metallic Gasket

Get Price Quote

We offer a wide variety of semi metallic gaskets which are manufactured using high quality raw materials such as nickel, titanium, monal, inconel, stainless steel, copper, aluminum, ceramic, graphite, asbestos and several other materials. These gaskets are available in the range of Spiral wound, metal jacketed and exchanger gaskets, KAMM profile grooved gaskets and metal reinforced graphite gaskets. They are also consist of metal cover and soft sealing material filler. These gaskets have temperature range from cryogenic to 1000 c and high vacuum to over 350 bars. We offer good performance on difficult dry gas on high vaccum applications. Semimetallic gaskets are widely used in Steam, Petrochemicals, Marine, Nuclear and High Pressure line flanges.

metal jacketed gasket

Get Price Quote

Metal Jacketed Gaskets consist of a metallic outer shell with either metallic or non-metallic compressed fiber filler. The filler material gives the gasket resilience, while the metal jacket protects the filler and resists pressures, temperatures, and corrosion. Special used in sealing spots of heat exchanger, pressure vessel etc. This gaskets highly resistance against blow-out suitable for high assembly stress.

corrugated metal gaskets

Get Price Quote

We are ranked among renowned Manufacturers, Exporters and Suppliers of Corrugated Metal Gaskets in Tamil Nadu, India. Made from flexible graphite sheets, our gaskets are suitable where there is low bolt load or high available gasket stresses. Buyers can get Corrugated Metal Gaskets from us as per requirement at market leading prices. In addition, we offer customized Corrugated Metal Gaskets to meet varied demands of customers.

Metal O Ring Gasket

676 Per Piece

spitmaan metallic gasket sheet

150 Per Kilogram

50 Kilogram (MOQ)

Spiral Wound Metallic Gaskets

Get Price Quote

Construction : Special Spring like Metal strips are wound with an Asbestos Filler by a special process to assure a leak proof seal. The sealing is done by the Asbestos Filler and the metal strip provides the spring. This combination of metal and soft asbestos Filler piles compresses to its predetermined thickness under bolting pressure and thereby preventing leakage within the limit of its specified pressure and temperature ranges. With the addition of Centering devices, adapt "SPITMAAN" Spiral Wound Gaskets to use on many types of flanges and closures. Materials : Standard materials are type 304 Stainless steel with white Canadian (Chrysotlie) Asbestos Filler. Hints Of Installation & Maintenance: When installing a Spiral Wound Gasket, check the dimensions of the Gaskets for use between pipe and pressure vessel flanges. The procedure is as follows:- Measure ID of flange contact face. Measure Gasket ID. If Gasket ID is not 1/8" larger than flange ID, do not use it unless it can be installed perfectly centered. A Spiral Wound Gasket does not have the same feel as other Metallic or Non-Metallic Gaskets during the bolting-up. It's different-because it gives a little bit under each bolt as it is tightened. It is therefore important to tighten the bolts in small steps in proper sequence as shown hereunder. Final tightening must be uniform with each bolt pulling same load. This will guarantee a trouble free joint. If not uniform, the joint may leak-particularly after it has been in hot service. Tighten the bolts after 24 hours and again a week later. How To Order: When ordering "SPITMAAN" Spiral Wound Gaskets, give the following information: Quantity Gasket shape Inside and outside Dimension of Gaskets Flange width Gasket Thickness Operating Pressure Operating Temperature