Back Part Moulding Machine

Get Price Quote

Pet Stretch Blow Moulding Machine

Get Price Quote

The PET bottle is a great success in many countries. An no wonder, produced by the biaxially oriented blow moulding process, PET or Polyethylene Terephtalate bottles combine outstanding performances and aesthetic qualities. They give you the superb crystal clarity needed to show any product to advantage. They have excellent carbonation retention properties and a good barrier to oxygen. Its extremely resistant to breakage, Light to handle, Easy transport and safe to health and environment.With Seppa Fillers System Flexibility To the advantages of PET itself, the extraordinary characteristics of SSB 10 to SSB 60 are added simplicity, compactness, reliability and flexibility. Quickly installed, the machine is ready for producing bottles of various shapes and contents as the changes of the moulds are rapid. Renowned for these advantages, it is the small two step machine which is the most sold in the world and give satisfaction to hundreds of producers for very different applications: Mineral water, carbonated drinks, Edible oil, Detergents. This is the ideal system for the economical production, in small series, of quality bottles. The Quartz Oven Eight vertically, horizontally and angularly adjustable double lamps can be turned to allow a more uniform heating of any type of performs before blowing. Preheating is achieved by re-circulating hot air exhausted by lamps and the system automatically adjusts to changes in the ambient temperature. An oven with ten lamps (Optional) permits the heating of thicker performs. The SEPPA system is well known for its solidity and reliability according to world standards and great success in many countries for PET bottle blowing machine. The Control CabinetThe control cabinet is equipped with a programmable microprocessor with Error Status Indicator. Setting and adjusting of the controls can be performed manually. For special climates the cabinet can be air conditioned.Easy AccessThe pneumatic, hydraulic and electrical equipments, as well as the cooling system, are easily accessible. Minimum replacement time is required when one type of bottle mould is changed for another one. No special are needed.The Bi-axial Orientation PET is certainly the ideal material, but to retain that title, it also needs the full benefits of bi-axial orientation. Bi-axial orientation requires two – stage production; the perform is first produced and then, within a precise temperature range, it is simultaneously stretched both axially, thanks to stretching rods and radically by blowing. It is this process which gives the container its strength. These two phases can be carried out on one double acting machine (one stage) or separately on two different machines two stages. But the new generation of applications is covering a still more extensive range: detergents and cleaning products, wine and other alcoholic-drinks, fruit juices, certain conserves, sauces, ketchup and mustard, cosmetic and pharmaceuticals products, industrial paints and oils, chemical products etc. Its a range of new markets with a promising potential. Specialized in the manufacture of bi-oriented stretch blow moulding machines for PET Containers (starting from performs) Seppa is offering today a completely up-graded range of small and medium capacity blow moulding units. They combine the proven simplicity and reliability of the linear machine concept with the most recent developments in the field of PET process technology. A state of Art, User friendly operator machine interface graphic display allows easy programming of all relevant production parameters, ensuring at the same time extremely fast product change-over. Special equipment packages are available for the production of refillable or hot fill PET Bottles. PEN PET bottles and bi-oriented PP bottles. Advantages of a Flexible System A system of small modular units has many advantages over one large machine. You can begin small with the minimum investment. As business grows, additional units can be acquired. Production volume can easily and economically be adjusted to market fluctuations. Bottles of different sizes and weights can be produced simultaneously on different units. Change over from one production to another can be rapidly effected.The equipment design is simple and, as a result, the tooling costs are low. The SEPPA system is well known for its solidity and reliability according to world standards. A simple system to operate means short training for operators.As the machine requires very little maintenance costs related to non operating machines are negligible.

Best Deals from Molding Machine

vertical moulding machine

Get Price Quote

Dual-cylinder injection system offers high injecting pressure for fast operation, making this Rotary Vertical Injection Moulding Machine your best choice for production of thin items.Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions.

SPRUE PICKER ROBOT

150,000 Per Set

The sprue picker, a simple pick-and-place robotic device was intended as a low cost method of sprue removal or part and runner separation in the injection molding process. In most cases the low cost of these sprue pickers is maintained by employing a pneumatic motion system as the basis for their design. However, this design configuration provides a low cost robot at the expense of system durability, accuracy, speed and functionality. These desirable and needed features, inherent to the servo driven motion systems, seem unattainable in the present environment of cost conscious sprue picker applications

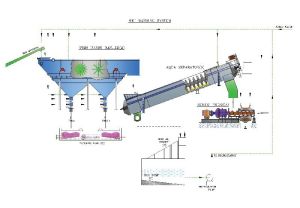

Wet Washing System

Get Price Quote

* Removes pith and silica by 70-80% * Dissolves chlorides & Soluble chemicals * Eliminates pith, Nodes and fines * Reduces steam, Cooking and Bleaching chemicals by 15- 25% Depending upon the required capacity the price of the unit will vary.

Micropower Injection Molding Machine

Get Price Quote

Offers micropower injection molding machine. Wittmann battenfeld as a system supplier of cost-efficient solutions all from a single source has also adapted the entire range of peripheral equipment to the production of small and micro parts, from material feeding devices and material dryers for small volumes and throughputs to tempering systems with corresponding performance levels. Main benefits: wider processing window. Higher dimensional stability of parts. Less warpage of parts. Less degradation of plastic materials. Less rejects. More stable production.

compression molding machine

800,000 - 9,200,000 Per Piece

Hydraulic Compression molding press from 50 tons to 3000 tons . Platen size 500 x 500 mm to 2500 x 1500 mm sizes . with PLC controls , hydraulic units and conveyors

Fully Automatic 2000,4000,6000 BPH

Get Price Quote

5 Set(s) (MOQ)

Technical advantages and features operator’s safety reliable and durable components are protected by mechanical and electrical safety systems. Precision sensors for safety of machines. High quality cylinders, valves and controllers to enhance machine’s endurance. High production output for an given electrical consumption . Closed production zone and good self-lubrication systems to avoid contamination of preforms. Advanced plc with touch screen control system with a user-friendly control panel and time-control precision of plc. Automation with actual running parameters on touch screen display for easy monitoring. Auto-feeder for pre-forms to reduce manpower. In built cooling system for neck cooling, mold cooling and oil cooling to reduce rejection rates. Infrared pre-form heater of 2kw. Independent temperature control for different heating lamps can be set in the touch screen in a single page accurately, to get ideal pre-form heating results. Constant quality of bottle production is based on the precision rotation of pre-form mandrel and stretch motions. Moulds can be removed and fixed easily within minutes by a single person. No stretch rod adjustment required for different bottle productions. Machine maintenance and testing can be done in manual mode. Easy maintenance, absolute safely, visual inspection, low noise. Rejection rate of finished bottles are very less.

Plastic Blow Moulding Machine

Get Price Quote

We are offering plastic blow moulding machine. Plastic blow moulding machines. We developed our technical field to match the new trend of modern technology. We are manufacturing hi-tech automatic plastic blow moulding machines starting capacity of â½litres to 200litres. Gradually we have developed our technology to manufacture plastic injection moulding machines. We are manufacturing hi-tech automatic plastic injection moulding starting capacity of 60gms to 400gms.

Seppa SSB - 2D Auto Drop Semi Automatic Pneumatic Pet Blowing Machine

Get Price Quote

1 Piece (MOQ)

Machine for the production of PET bottles 90ml – 2000 ml SSB-2D is a 2-cavity, Semi-Automatic, PNEUMATIC blow moulding machine dedicated for production of PET bottles 90ml-2000ml with capacity 1000-1400 bph for 500ml bottles. One of its key advantages is the efficient oven with special lamps (IR) for plasticising preforms. Another advantage of this machine is it is small compact and low investment machine for low quantity production of small bottles. SSB-2D machine meet the requirements of companies that expect high quality packaging, efficient work and minimisation of production costs. Key features: Capacity 1000 bph for 500ml and up to 1400 bph for 500ml, pressure of high blow 20 bar High-performance oven for bottles plasticising Manual preform loading and bottle realising High quality components: Mitsubishi,Allan Bradley, Norgen, Schnider , Festo, Smc , Delta, Siemens, Panasonic, and other recommended brands Quick mould ex-change system Electrical Box and Plc system based on leading brands components Compact size

Pet Bottle Blow Molding Machine

101,250 - 4,000,000 Per piece

1 Piece (MOQ)

Insert Moulds

Get Price Quote

Used in Telecom, Metal, Plastic, Electrical and Automotive sectors, the Insert Moulds, which we offer, are known for their reliability. We are trustworthy Manufacturer, Supplier and Exporter of the Insert Moulds from Chennai (Tamil Nadu). Usually, metal Insert Moulds, which we offer, are embedded into plastic during molding process. These Insert Moulds eliminate assembly process, and are used when the fastening between metal and plastic needs to be permanent. Raw Materials Used : P20, H11, H13, STAVAX, etc. Availability : Maximum Size - 1000 x 1000

pvc paver moulds

117 Per Kilogram

500 Piece(s) (MOQ)

100% Natural & Vegin Material finished & Shinning Quality Long Life

Servo Motor Injection Moulding Machine

150,000 Per Piece

1 Piece (MOQ)

CNC Mold Forming Machine- Autolinkcnc

1,354,108 Per Piece(s)

AutolinkCNC - We are a global supplier of CNC wire Bending Machine, CNC WIre Forming Machine, CNC Spring COiling Machine, Furnance, CNC Ring Making Machine, Buckle Making Machine, Spring Grinding Machine, Mold Forming Machine and CNC WIre Straightening and Cutting Machine in various models available here.Input Materials: Stainless Steel, Aluminium, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc. The input wire diameter ranges between 0.3mm and 2.0mm. Shipping Terms : FOBAdditional Cost for the Import Of machines Extra Tools (Apart from free tools along with machine) CIF Cost (If required) Notes Price will be updated if Exchange rate chan 0162 ges lot. Agent price is only for the one who willing to sell our machines and we have chance to work with them. But not final agent price.

Plastic Blow Molding Machine

2 - 16 Per Litres

We are plastic blow molding machine manufacturer in chennai. Water cane making machines. Container making machines.

Injection Molding Machine Controller

Get Price Quote

1 Piece(s) (MOQ)

N2S Technologies Pvt Ltd is the well-known supplier and solution provider of IMM Injection Molding Machine Controller in India. Our versatile and efficient controllers are designed specially to meet the automation needs of plastic molding machines. It is cost-efficient and suitable for simple hydraulic injection molding machines to complex and multi-component systems. We will provide you with the best IMM Controller series at attractive prices.

Plastic Blow Mould

12,000 Per Piece

plastic bottle cap moulding machine

7,500,000 Per UNIT

1 UNIT (MOQ)

Blow Moulding Machine

Get Price Quote

We are offering blow moulding machine. u.v. Tech india: your quality automatic blow moulding machine manufactures. Wider mouth. Faster production rates. Round, square or any styles. Labor saving

Blowing Shankh

450 Per Piece

01 Piece (MOQ)

Pet Blow Molding Machine

Get Price Quote

We provide our clients with a range of pet blow molding machine and bottle blowing machines, which are used to manufacture the bottles of any possible geometrical figures. These machines fabricate bottles having excellent carbonation retention properties and good barrier to oxygen. Our range of blow molding machine is used for PET bottles ranging from 30 ml to 2000 ml. These are fabricated using high grade material and cater to the requirements of various industries. Best known for effective performance and high efficiency, our range is offered at market leading rates to our clients. Specifications: 2 Cavity Bottle Blow Molding Machine Capacity 550-600 Bottles/Hr 4 Cavity Bottle Blow Molding Machine Capacity 1300-1400 Bottles/Hr.

Water Channel Moulding Machine

1,777,000 Per Piece

Rubber Injection Moulding Machine

700,000 Per Piece

Automatic Blow Molding Machine

Get Price Quote

A PENNY SAVED IS PENNY EARNED” at UV TECH we are holistically concerned about the resource utilization of our customer. The Air Recovery System in the Fully Automatic Blow Moulding Machine is a stand out testimony our “We Care” attitude. In the package beverage the rejection pertaining to empty bottles often is the thin line that decides the magnitude of success of the project itself There is often the misconception of subcontracting that forces the bottlers to procure blown bottles from small time vendors. This concept has fatal results when the rejectiondamage of the bottles due to transportation hit hard on the bottom line of the project. The other concept is to go in for semi automatic blowing machines, this seems to be a readymade solution for small timers whose filling line itself is not automated. This segment of the industry has very limited scope in terms of representing a bigger brand. Even in this case the handling rejection is often prohibitive. The fully automatic blow molding machine is considered a extravagant luxury in the bottling industry given the exorbitant cost of the machine, which is only supplemented by the ridiculously high operating cost and soaring electrical consumption.

Blow Moulding

Get Price Quote

Driven by the passion to provide nothing but the best, we have risen as trusted suppliers of Blow Moulding in the market. Based in Chrompet(India), we hold specialization in offering quality products that are the perfect outcome of premium material and modern manufacturing techniques.

Blow Molding Machine

Get Price Quote

We are offering blow molding machine.

Laser mould repair Machine

Get Price Quote

The working principle of this laser deposition welding system is to use laser high thermal energy and the melting technology in spot to process the welding and repairing of minute parts. It makes up the shortage of traditional hydrogen arc welding in repairing precision surfaces, avoids the two difficulties of thermal strain and after-treatment, and saves the production period of mould. Applicable Industries The laser deposition welding system (laser mould welder) is specially designed for the mould industry and used in repairing of precision moulds, such as mould manufacture for digital products, mobile phone, toy, automobile and motorcycle, and molding industry. Through the repairing of moulds, it is possible to reuse the moulds, save the production cost and improve the working efficiency significantly. This technology can also be used to modify the design or size of moulds to reduce the development period. Advantages With unique structure design, it is suitable for repairing of large, medium and small moulds. Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is more than 8 million times. Use the most advanced light shielding system to eliminate the irritation to eyes by light during working. The laser head and optics part can be rotated for 360° upward/ downward lifting and forward/ backward pushing, suitable for repairing of large, medium and small moulds. The parameters are controlled by intelligent remote controller, which is simple and convenient. The work bench can be lifted, and moved in three dimensions. The size of light spot can be adjusted.

Candle Mould Making Machine

Get Price Quote

Capacities shown above are only indicative and based on results obtained from our trials Using type – 2 candle wax. This may vary to any extent while using other types of wax depending upon the oil / fact contents.

plastic blow molding machines

600,000 Per Unit

1 Unit (MOQ)