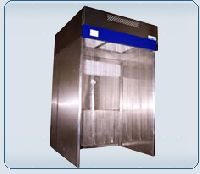

Powder Dispensing Booth

171,000 - 360,000 Per Unit

1 Unit (MOQ)

Powder Dispensing Booth

Get Price Quote

Dispensing Booths with its open-fronted design, this type of system affords comfort of access for product, operator and environment. Reverse laminar flow powder dispensing booths (Also called powder containment booths) protects the operators from toxic chemicals raw materials used for manufacturing of tablets, medicines, capsules etc from external contamination during the process of weighing or measuring. It is ideal where a high degree of flexibility is desired. Containment is achieved by air movement. Our down flow booths are workstation are available in a variety of air-handling models. When the Booths is operating under normal conditions air is pulled through the main working chamber to exhaust grills, normally situated in the rear of the Booths, suppressing air-borne dust away from the operators breathing zone. Down flow Booths and Workstation provide a safe, controlled working environment and are called upon to carry out a wide range of operations.

Best Deals from Powder Coating Machine Spare Parts

Powder Dispensing Booth

Get Price Quote

powder containment booth

Get Price Quote

powder containment booth, Modular Operation Theatre, Modular Clean Room

Reverse Flow Powder Sampling / Dispensing Booth

Get Price Quote

REVERSE LAMINAR FLOW POWDER DISPENSING BOOTHS (Also called POWDER CONTAINMENT BOOTHS) protects the operators from toxic chemicals / raw materials used for manufacturing of tablets, medicines, capsules etc from external contamination during the process of weighing or measuring. The Powder Sampling & Dispensing Booths are contains four important components such as: Return Air Primary Filter (also called as First Stage Pre Filters) Intermediate Secondary Filter (also called Second Stage Fine Filters Supply Air Final Filter (also called as Final Stage Mini-Pleat HEPA filters) Motorized DIDW / SISW blower unit When the Sampling / Dispensing booths are switched on, the blower unit creates a suction pressure through the primary filter & intermediate filter, which removes dust particles of above 10 micron & 5 micron size in the first and second stages. Subsequently, the partly filtered air passed to the HEPA filters, where the particles or substances of 0.3micron size and above are removed. Finally the ultra clean filtered air supplied to the working safe zone as a uniform airflow to perform precisionfor raw-material containment purpose

Powder Dispensing Booth

Get Price Quote

Powder Dispensing Booth, air shower entry systems, Scientific Instruments

Powder Containment Booths

Get Price Quote

Powder Containment Booths, Fume Hood, Fume Cupboards, Laboratory Trolleys

Powder Coating System Spray Gun

Get Price Quote

Powder Coating System Spray Gun, Flexiflo Powder Coating System

Manual Powder Coating Machine

Get Price Quote

Manual Powder Coating Machine, Electrical Panel Box Powder Coating

MS Powder Coating Machine

Get Price Quote

MS Powder Coating Machine