Wall Deslagger

Wall Deslagger soot blower are suitable for wall cleaning application such as furnace walls, generating tube banks or divisional wall tubes of any coal fired boiler Cleaning action achieved by projecting the lance tube with nozzles through a short distance into the boiler and rotating the nozzles by a set of degree of rotation with the blowing medium flowing through it Number of nozzles customized based on the specific application Motorized soot blower driven by a single motor Manual and motorized (with provision for manual operation) soot blowers available.

...more

Rotary soot blower

Rotary soot blower are used to clean convection surfaces of - boiler tubes, economizers or tubular reheaters of field erected or packaged industrial boilers Rotary soot blower are suited for environments with temperatures up to 800o C Adjustable cleaning area to suit user requirements Supplied with a mass blowing or lane blowing arrangement (refer following section) Suitable selection of nozzle and lance material as per application requirements Special design consideration for minimal bending of lance of tubes due to overheating Superior compared to conventional methods of cleaning Increases efficiency of the boiler / heater Prevents breakdown due to deposits Easy operation and maintenance Manual and motorized (with provision for manual operation) soot blowers available Mass Blowing Blowing medium is directed over a wide area to cover more than one lane - "shotgun" effect Blowing element has fewer nozzles of relatively larger diameter to effect widespread cleaning of three or more rows of tubes at a time Lane Blowing Blowing medium is directed down each tube lane - "rifle" effect Generally used in convection section of the boiler or in the case where there is not enough cavity space for mass blowing Elements use proportionally more nozzles of smaller diameter compared to the mass blowing arrangements.

...more

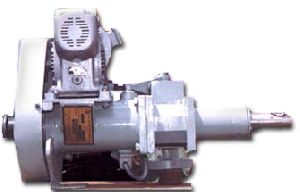

Retractable soot blower

Retractable soot blower - Designed for cleaning exchanger surfaces in case of Environments with high temperature gases (over 800o C). Infeasible to fit rotary soot blowers. Danger of meeting serious choking. Rotary soot blower are suited for environments with temperatures up to 800° C Standard Retractable soot blowers is fitted with two independently functioning drives for translatory and rotary motion Translatory drive for introducing and retracting the lance tube into the boiler / heater Rotary drive to provide the rotary action of the blowing arc for cleaning The lance tube remains outside the boiler / heater when not in operation to prevent overheating and melting of the lance tubes Can be fitted with a single drive for rotary and translatory motion if preferred Independent drives ensure retraction of lance in case of rotary drive failure, and avoids a lengthy duration of steam jet concentration on a particular area of boiler tube if failure of the translatory drive occurs Optimal design of angle of blowing of the nozzle to ensure through cleaning of the tubes. Manual and motorized (with provision for manual operation) soot blowers available.

...moreBe first to Rate

Rate ThisOpening Hours