Sheet Metal Pressed Parts

100 Piece (MOQ)

we manufacture any sheet metal pressed parts and the price will be desided based on the design. How we make this? Step 1 : First we will make tool for that Step 2 : Based on the profile we will decide the machine, Machines which are used are Hydraulic press, power press and pneumatic press Step 3 : Based on the profile operation will be done Example : Normal operation are as follows Blanking, Hole Piercing, Bending, Forming, Flanishing, Reforming, Notching, Grinding.

Material : Steel, Sheet Metal, Copper

Shape : Square, Round, Rectengular

Color : All

Application : Industrial Use

Feature : Water Proof, Tamper Proof, Heat Resistant, Fireproof, Durable Coating, Durable, Anti Rust

Country of Origin : India

...more

Banana Chips

400 - 450 Per kg

hi we sell al the products which are famous in kanyakumary and kerela

Application : Human Consumption

Packaging Type : Packet

...more

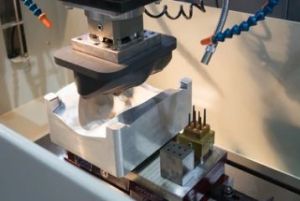

VMC Machining Job Work

150 - 600 Per hour

Why Choose Us: Proven Track Record: With years of experience, we have a proven track record of delivering precision VMC machining solutions to satisfied clients. Timely Delivery: We understand the importance of deadlines. Our streamlined processes ensure timely delivery without compromising on quality. Customer-Centric Approach: Our commitment to customer satisfaction is at the core of our business. We value open communication and transparency throughout the machining process.

...more

VMC MACHINE JOB WORK

200 - 600 Per hour

Vertical Machining Center (VMC) machine job work services provide precision manufacturing solutions. Our expert team utilizes VMC technology to create intricately crafted components with utmost accuracy. From prototyping to production runs, we cater to diverse industries, delivering high-quality parts with tight tolerances. VMC machining ensures efficiency, cost-effectiveness, and fast turnaround times. Whether you need single prototypes or large-scale production, our VMC machine job work service guarantees top-notch results, making us a trusted partner for your machining needs.

...more

Surface Grinding Job Work

200 - 1,000 Per hour

Surface grinding job work is a machining process used to achieve precise and flat surfaces on workpieces. It involves the use of a rotating abrasive wheel to remove material from the workpiece's surface. This process is crucial for achieving tight tolerances and a smooth finish on components, making it ideal for industries like automotive, aerospace, and tooling. Surface grinding job work is commonly applied to produce precision parts, molds, and tools, ensuring that they meet the required specifications and quality standards.

...more

Precision Cnc Machining Service

600 - 2,800 Per hour

Precision CNC machining services offer high-accuracy, custom part production using computer-controlled machines. These machines remove material from a workpiece to create intricate, precise components for various industries. With advanced technology and skilled operators, CNC machining ensures tight tolerances and repeatability, guaranteeing top-quality parts. From prototypes to mass production, CNC machining caters to diverse needs, including aerospace, automotive, medical, and electronics sectors. This process enables efficient, cost-effective manufacturing with minimal waste, making it an essential solution for complex and detailed projects.

Country of Origin : India

...more

Lathe Machine Turning Job Work

200 - 1,000 Per hour

Lathe machine turning job work is a fundamental machining process used to create cylindrical components or modify existing ones. It involves rotating a workpiece on a lathe and using cutting tools to remove material to achieve the desired shape, dimensions, and surface finish. This versatile technique is applied across various industries, such as aerospace, automotive, and manufacturing, to produce components like shafts, pins, and threaded parts. Lathe machine turning job work is known for its precision and versatility in producing a wide range of parts.

...more

Laser Cutting Job Work

100 - 500 Per hour

Laser cutting job work is a highly efficient and precise manufacturing process that utilizes a focused laser beam to cut through various materials, including metals, plastics, and woods. It is widely used in industries for creating intricate shapes, patterns, and custom parts. Laser cutting provides exceptional accuracy, minimal material waste, and the ability to work with a wide range of materials. It's commonly employed in sectors like sheet metal fabrication, signage, and architectural modeling, where clean, precise cuts are essential for high-quality results.

...more

EDM Spark Job Work

300 - 600 Per hour

EDM spark job work, or Electrical Discharge Machining, is a precise and versatile metalworking process. It involves using electrical discharges to remove material from a workpiece, creating intricate shapes and fine details. EDM spark job work is particularly useful when working with hard or difficult-to-machine materials, such as hardened steel or exotic alloys. This process is commonly applied in industries like aerospace, automotive, and tool and die manufacturing for producing complex, high-precision parts, molds, and prototypes with exceptional accuracy and surface finish.

...more

cylindrical grinding job work

300 - 900 Per hour

Cylindrical grinding job work is a machining process that focuses on precision grinding of cylindrical parts. It is commonly employed in manufacturing and engineering industries to attain tight tolerances and a superior surface finish on components. During cylindrical grinding, a rotating abrasive wheel removes material from the exterior of the workpiece, ensuring cylindrical shapes or achieving specific diameters. This process is vital in producing components like shafts, rods, and spindles, where precise dimensions and a smooth finish are critical for functional and aesthetic purposes.

Material : Hardened material

...more

Cnc Milling Job Work

300 - 500 Per hour

CNC milling job work involves the use of Computer Numerical Control (CNC) machines to precisely shape and cut materials. This versatile machining process is commonly used in manufacturing to create components for various industries. CNC milling offers exceptional accuracy, repeatability, and the ability to work with a wide range of materials, from metals to plastics. It's well-suited for producing complex parts, prototypes, and custom components with high precision. CNC milling job work is essential for industries like aerospace, automotive, and medical device manufacturing.

...more

CNC EDM Wire Cut Job Work

400 - 1,000 Per hour

CNC EDM wire-cut job work is a precision machining process utilizing Electrical Discharge Machining (EDM) with a computer numerical control (CNC) system. It involves using a thin, electrically charged wire to precisely cut and shape materials, typically metals, with extreme accuracy. This method is ideal for creating intricate parts, molds, and prototypes. CNC EDM wire-cut job work ensures high precision, fine finishes, and minimal material wastage, making it a preferred choice for industries that require complex and tight-tolerance components, such as aerospace, automotive, and tooling.

...moreOpening Hours

Raja Tools was established in the year 2003 in Tamil Nadu, India. We are manufacturers of sheet metal pressed parts.

The company’s highly driven workforce, global outlook, rich product portfolio, and futuristic design & development parameters are the key factors that set it apart within the industry.

The fine-tuned design cues of Raja Tools have ensured the winning of prototype development projects from the leading manufacturers in the Automotive Ancillary and FMCG sectors worldwide. This has further strengthened the company’s capabilities to carry out the product design & development processes for applications in diversified high-growth industry verticals.

Constant Innovation, Unmatched Cost and Quality Advantages

Right since its inception, Raja Tools has focused on technological innovation, quality orientation, and a well-defined and principled approach towards customer satisfaction. Apart from these, the company’s decades of proven expertise in designing, development, tooling, manufacturing, and testing capabilities have helped it achieve both cost and quality advantages.

Vision

To be a global leader and a brand of choice for our valued customers, an employer of choice for our employees, and a forward-looking company with sustainable performance and responsible business practices.

Mission

Raja Tools has an action plan to achieve all its goals by approaches stated below