Salt Spray Test Chamber

190,000 Per Piece

Salt Spray Test Chamber

Get Price Quote

Cabinet constructed from non-corrodible high temperature resistant glass reinforced plastic. Acrylic cover is provided. Constructed in fiber-reinforced plastic, 10 mm thick with stiffners at the bottom to take heavy load. The FOG Chamber conforms to ASTM B 117 specification. The volume is of sufficient size to test adequately the desired number of parts without overcrowding. The apparatus consists of a fog chamber, a salt solution reservoir, a supply of moisture free compressed air, atomizing nozzles, specimen supports, provision for heating the chamber, humidifying chamber and control system. The fog chamber is provided with digital temperature controller, pressure gauge, provision for controlling the mist, humidity indicator and solenoid valve to regulate these conditions.

Best Deals from Salt Spray Test Chamber

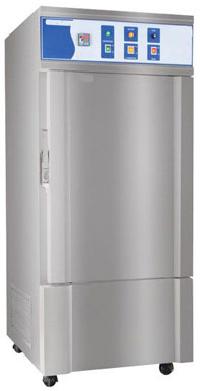

TLPPL 137 TECHNICO SALT SPRAY CORROSION TEST CHAMBER

Get Price Quote

Technico salt spray test chamber entire is constructed by thick polypropylene or acrylic sheet body. The top lid door will be made of transparent Acrylic. The solution reservoir is separated externally in a cylindrical vessel and fixed to the side of the main chamber. The solution is sprayed inside the chamber by means of compressed air (Air compressor not in our scope) and its level is controlled by float valve. The main chamber is provided with transparent acrylic cover lid mounted on fabricated acrylic hinges. The top lid closes the entire chamber without fog leakage. The saturation tower and the control panel are attached with the sidewall of the main chamber. The control panel is made of FRP material. Solution and water drain out tap are also provided. Suitable specimen holders and job holding devices are furnished inside the chamber. Technical Specification: Chamber temp. : 35 C Control accuracy : 3 C Saturation tower temp. : 40 C to 45 C. Controller type : PT- 100( RTD type) Temperature controller: Size : 48 x 48 mm Type : Digital Humidity Indicator: Size : 48 x 48 mm Type : Digital Digital Timer: Make : Selectron Size : 72 mm x 72 mm Hours : 999.9 hrs Pressure gauge: Range : 0 – 4.2 kg/cm2 Range : 1 kg/cm2 (saturation tower). Solution tank : 5 % of the sodium chloride (100 lit) is prepared and poured in the chamber reservoir. It is passed to the spray tower through the mechanical float through which is maintaining the water level in the tower. POWER SUPPLY: The chambers plug pin should be connected to the power supply & the timer to be set according to the testing hours. PRESSURE REGULTOR WITH GAUGE: The compressed air enters to the solenoid valve. It is controlled by the help of pressure regulator (15 lbs.) in pressure gauge. When the testing specimen or components are loaded to the chamber. The drain out valve is kept open because the condensed for water should not touch the specimens STANDARD SIZE: 600 x 600 x 600H or 600 x 900 x 900H.