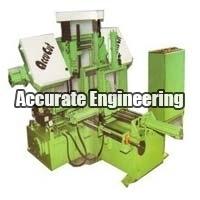

Heavy Duty Metal Cutting Bandsaw Machine

945,000 Per Piece

1 Piece (MOQ)

The heavy duty bandsaw machines offered by us is used for processing metal and various other materials. Our bandsaw machines come in 260 mm to 1500 mm cutting capacity. The machines we make available have the capacity to cut any material with ease at high speed. It is hydraulically controlled machine with coolant motor.

Metal Detecting Machine

230,000 Per Piece

1 Piece (MOQ)

Best Deals from Sheet Metal Machinery

CNC Laser Metal Cutting Machine

1,800,000 - 10,000,000 Per Bag

sheet cutter machine

Get Price Quote

Metal Detector Machine

Get Price Quote

1 Piece (MOQ)

Sheet Metal Laser Cutting Machine

2,800,000 - 7,500,000 Per Box

1 Box (MOQ)

Moon Laser is an economical fibre laser cutter with a small investment that runs at full speed at a low cost. The Economical Sheet Fibre Laser Cutting Machine is a 1000W laser cutting machine specially designed for the advertising industry to cater to the increasing demands of metal advertising products. The economical and practical laser cutter adopts a high-rigidity enhanced lathe bed, an advanced laser source, and top-rated transmission parts to ensure high-performance cutting.

flange facing machine

Get Price Quote

This is a process by which Raw MillCement Mill Trunnion Journals can be repaired by INSITU machining at site. The scorings formed over a period of time, can be removed and the Trunnion Journal diameter will be undersized to standard diametrical tolerances as per OEM's specification. The Trunnion Journal will be stationary while our INSITU attachment will rotate around to effect grinding. This will generate true spherical surface. Using this state of art INSITU machine, any shafts upto 3200mm diameter can be INSITU machinedground

Sheet Pressing Machine

Get Price Quote

To Press a whole lot of Corrugated sheets after pasting in order to avoid bubbles free & even board. Sizes Available : 45” x 52” & 62” x 72”

sheet metal forming

Get Price Quote

Wire Mesh Fence

Get Price Quote

Wire mesh fence It is used in operations to pave the field after the installation of a blade barrier. This product can protect you and your property, and ensures the safety of the protective barriers.

sheet metal cutting machine

Get Price Quote

NOn metal laser

Get Price Quote

Offering Non Metal Laser Cutting Machine. Non Metal Laser is most suitable and the preferred choice of equipments in industries such as advertisement, gifts, shoes, toys, and etc. Non metal laser is equipped with Texas 32 Bit DSP control system, there is a Flash memory on the mother board, you can download the work file to the machine via USB cable.

Sheet Metal Laser Cutting Machine

Get Price Quote

YAG 500W Sheet Metal Laser Cutting Machine integrates optical, mechanical, and electricity in one, which adopts laser, computer control technology and high-performance CNC laser power system. The cnc laser cutting machine is applied to cut stainless steel, carbon steel, alloy steel, spring steel, aluminum, silver, copper, titanium and some metal plate and pipe. Widely used in sheet-metal structure, high-low-voltage electrical cabinet production, hardware, knife-volume, production of advertising signs, metal crafts, decoration aviation, mechanical parts, electical meter, sawblades, spring-chip and other industries. Features The outside sliding guide ensures fast processing speed, which is especially suitable for the garment and leather industries. Being integrated with more concise frame, this machine is more economical but still have the same excellent cutting and engraving effects. Our three unique protection functions, i.e. anti-interference function, water-protective function and power cut-off function ensure longer working life, stability and effectiveness. The stainless steel honeycomb platform we adopt, which is breakage-proof, ensures stable focus distance thus good cutting and engraving quality. Original Singapore imported lens with molybdenum base makes the equipment produce smaller facula and stronger cutting force, greatly improving working efficiency and reducing cost. Exhausting, absorbing and assistant blowing systems solve the problem that troubles the laser equipments manufacturing industry for years, extending the life of the laser tube. This machine uses USB port to transmit data, equipped with large-capacity internal memory, improving working speed and efficiency greatly.

Laser Metal Engraver machine

Get Price Quote

L.M. guide-ways for all axes Pre-Loaded ball screws for all axes Centralised lubrication system AC Servo Drive for all axes 10,000 PRM High Frequency Water cooled spindle Manual Pulse Generator Air blast for spindle taper cleaning Fully covered machine Telescopic covers for all 3 axes

Growing Profiling Machine

Get Price Quote

We are offering growing profiling machine. this machine is to profile bangle and ring in any shape accurately. It has additional facility to operate manually. Precision depth setting device to control gauge, profile and diameter of bangles and rings.

Metal Detecting Machine

265,000 Per Piece

1 Piece (MOQ)

Roofing Sheet Making Machine

Get Price Quote

Laser Metal Cutting Machine

2,300,000 Per Piece

Ultrasonic Metal Welding Machine

Get Price Quote

Product Introduction : Ultrasonic Metal Welding Machine conducted ultrasonic energy melts down the joint face of the work piece after rubbing the joint face violently with ultrasonic frequency at the speed of tens of thousands of times per second and with certain amplitude. The transient pressure maintained at the work piece after stopping vibration makes two pieces of weldment solidify together in the form of molecular interlinkage. The principle of Ultrasonic Metal Welding Machine:Ultrasonic welding is a kind of solidoid welding method, the jointing of metal work piece is by acoustical system high frequency vibratioon and clamping of static pressure between work piece. The ultrasonic generator is frequency conversion device, it transfers the power current into oscillating current of ultrasonic frequency, transducer transfers the ultrasonic frequency electrical energy into mechanical energy. The amplificator is used for magnify amplitude and coupled load. Under function of the static pressure and elastic vibration energy, the metal work piece transfer elastic vibration into friction energy between work piece, deformation energy and thermal energy, there are a oxidation film on the face of two work piece and realize the friction welding. When weld metal with different material, it can formed compound molecule connector, and realize metallurgy welding. * Characteristic of Ultrasonic Metal Welding Machine:Welding: to-be-weld metal work pieces overlaped, it will be jointed as solid state through the ultasonic vibration & presssing, the joint part don’t have the defect of cast structure (rough surface).Mould: compared with electric resistance welding, the mould ultrasonic welding has long life time, mould renovate and replace time is less than it, and easy to realize automation. Advantages: don’t need soldering flux, metallic stuffing, external heat and other external factors. * Advantages of Ultrasonic Metal Welding Machine:Save cost: avoiding unnecessary material cost, such as welding flux or brass etc. Long life time tooling: tooling of ultrasonic welding mahine is adopt high quality steel, it has excellent abrasion resistance, and easy to be installed. Different metal welding: for same or different metal all have a good welding permeate effect. * Application of Ultrasonic Metal Welding Machine:Auto: auto wireRefrigeration: copper pipe sealing in refrigerator or air condition etc. Battery: multi layer of power battery, NI-MH battery net nad NI sheet welding, lithium battery, polymer battery and NI (AL) sheet welding. Switch:electromagnetics switch, no-fuse switch and other big current junction or contact.

Sheet Pressing Machine

Get Price Quote