Spiral Wound Gasket

Get Price Quote

We manufacture Spiral Wound gaskets in a variety of styles to suit the particular flange facing being utilized on the flanges.

Spiral wound gaskets

Get Price Quote

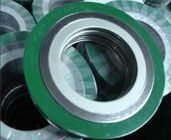

Driven by the need of providing an effective sealing solution in the industries, we offer a wide range of Spiral Wound Gaskets. Through precision engineering, the Spiral Wound Gaskets we offer are available in unlimited configurations of high quality metals and material to meet the varying demands. Spiral Wound Gaskets fill the space between flange bore and inside diameter of the machine to reduce turbulent flow. Furthermore, Spiral Wound Gaskets are manufactured in compliance with international specifications such as ASME 16.20, DIN, JIS and API.

Best Deals from Spiral Wound Gasket

Spiral wound gaskets

Get Price Quote

Spiral Wound Gasket

Get Price Quote

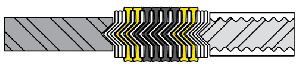

Spiral Wound Gaskets (SPW Gaskets):- At Goodrich Gasket, we manufacture Spiral wound gaskets by spirally winding a preformed metal strip and filler on the outer periphery of metal winding mandrels whose outside diameter form the inner diameter of the gasket and superposed metal and non-metallic windings are continually wound until the required outer diameter is attained. Compatible with the flange closure in which it is to be used, spiral wound gaskets can be used over the complete temperature range from cryogenic to approximately 2000º degrees Fahrenheit and in all pressures from vacuum to the standard 2500 psi flange ratings making it a high pressure and high temperature gasket. They are more resilient than any other type of metallic gasket with higher flexibility and recovery characteristics to maintain a seal under variable working conditions.

Spiral Wound Gasket

Get Price Quote

A gasket is a crucial component used to create a seal between two or more surfaces, preventing leaks of fluids or gases and reducing vibrations and noise. Typically made from materials such as rubber, metal, compressed fiber, or PTFE, gaskets are designed to accommodate minor surface irregularities and provide a tight, reliable seal. In various applications, gaskets are chosen based on factors like temperature, pressure, and the type of fluid or gas being contained. For instance, rubber gaskets are flexible and commonly used in plumbing and automotive systems, while metal gaskets are preferred for high-temperature or high-pressure environments. PTFE gaskets are known for their chemical resistance, making them ideal for corrosive substances. Proper installation is essential for effective sealing, involving clean surfaces and correct torque settings to avoid leaks. Regular inspection and maintenance ensure gaskets continue to function properly over time, preventing costly downtime and damage. Overall, gaskets play a vital role in maintaining the integrity and efficiency of mechanical systems across various industries, from automotive and industrial to plumbing and aerospace.

Spiral Wound Gasket

Get Price Quote

we are offering spiral wound gasket. ss304 ss316 ss316l ss304l

SPECIALTY SPIRAL WOUND GASKETS

Get Price Quote

DELTAONE Inhibitor gasket provides corrosion resistance in the most extreme conditions. It combines a HTG filler configuration with highest purity graphite, and a Kammpro inner ring laminated with soft PTFE material. The design of the Inhibitor gasket utilizes the Kammpro inner ring to provide the primary sealing interface. The inner ring material and its covering layer are inert in terms of corrosion through contact with dissimilar materials. This fire safe design incorporates the sealing integrity of highest purity graphite in conjunction with mica on the ID and OD, preventing the entrance of further corrosive conditions to the media.

Spiral wound gaskets

Get Price Quote

The Spiral Wound Gaskets are composed of a metallic continuous stripe with a special shaped profile, coupled with a continuous filling stripe (Asbestos, PTFE, Grafoil, Ceramic etc) evenly wound in concentric spiral under constant stress. The Spiral Wound Gaskets are reinforced on the inner and outer diametre by winding of several electrically welded spiral metal only.

Spiral wound gaskets

Get Price Quote

We are offering spiral wound gaskets. Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties. Spiral wound gaskets are used in refinery, petrochemical, chemical, steam lines and process industries, where they have many advantages over older types of gaskets. These gaskets are manufactured to international specifications such as bs, api, asme, din. We also manufacture to customer's specifications we have a huge capacity to produce precision machined components.

Silver Spiral Gasket

10 Per Piece

Style JG Spiral Wound Gaskets

Get Price Quote

We are offering bright bars. The standard gasket choice for rf and ff flanges, with the guide ring and sealing element made to asme b16.20din standards.

Spiral Wound Metallic Gaskets

Get Price Quote

Special Spring like Metal strips are wound with an Asbestos Filler by a special process to assure a leak proof seal. The sealing is done by the Asbestos Filler and the metal strip provides the spring.

Spiral Wound Gasket

Get Price Quote

We offers a complete range of spiral wound gaskets, Standard and non-standard spiral wound gasket. Gaskets can be made from a large selection of alloys and filler materials in a variety of shapes and sizes. The gasket is suitable for flange, valve, pump, heat exchange etc.

Spiral Wound Gasket

100 Per Piece

50 Piece(s) (MOQ)

Spiral Wound Gasket

Get Price Quote

Spiral wound gaskets

Get Price Quote

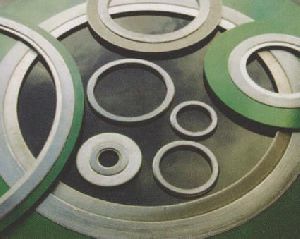

Spiral Wound Gaskets are special semi-metallic gaskets of great resilience; therefore they are very suitable for applications featuring heavy operating conditions. SWG manufactured by spirally winding a V-shaped metal strip and a strip of non-metallic filler material, The metal strip holds the filler, providing the gasket with mechanical resistance and resilience. SWG can be reinforced by an outer centering ring and/or inner retaining ring, The outer centering ring controls the compression and holds the gasket centrally within the bolt circle, The inner retaining ring increases the axial rigidity and resilience of the gasket and acts as a Heat and Corrosion barrier eliminating turbulence between the gasket Inner diameter and the flange bore so avoiding erosion of the flange faces.

Spiral Wound Gasket

Get Price Quote

Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties. Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets. These gaskets are manufactured to International specifications such as BS, API, ASME, DIN. We also manufacture to customer's specifications We have a huge capacity to produce precision machined components.

Spiral wound gaskets

Get Price Quote

Spiral wound gaskets (SWG) can be manufactured in several configurations of materials, range of dimensions and shapes. ASME B 16.20 covers materials, dimensions and markings

Spiral Wound Metallic Gaskets

Get Price Quote

Construction : Special Spring like Metal strips are wound with an Asbestos Filler by a special process to assure a leak proof seal. The sealing is done by the Asbestos Filler and the metal strip provides the spring. This combination of metal and soft asbestos Filler piles compresses to its predetermined thickness under bolting pressure and thereby preventing leakage within the limit of its specified pressure and temperature ranges. With the addition of Centering devices, adapt "SPITMAAN" Spiral Wound Gaskets to use on many types of flanges and closures. Materials : Standard materials are type 304 Stainless steel with white Canadian (Chrysotlie) Asbestos Filler. Hints Of Installation & Maintenance: When installing a Spiral Wound Gasket, check the dimensions of the Gaskets for use between pipe and pressure vessel flanges. The procedure is as follows:- Measure ID of flange contact face. Measure Gasket ID. If Gasket ID is not 1/8" larger than flange ID, do not use it unless it can be installed perfectly centered. A Spiral Wound Gasket does not have the same feel as other Metallic or Non-Metallic Gaskets during the bolting-up. It's different-because it gives a little bit under each bolt as it is tightened. It is therefore important to tighten the bolts in small steps in proper sequence as shown hereunder. Final tightening must be uniform with each bolt pulling same load. This will guarantee a trouble free joint. If not uniform, the joint may leak-particularly after it has been in hot service. Tighten the bolts after 24 hours and again a week later. How To Order: When ordering "SPITMAAN" Spiral Wound Gaskets, give the following information: Quantity Gasket shape Inside and outside Dimension of Gaskets Flange width Gasket Thickness Operating Pressure Operating Temperature

Spiral wound gaskets

75 Per Piece

Spiral wound gaskets

Get Price Quote

We are instrumental in Manufacturing, Supplying and Exporting Spiral Wound Gaskets from Tamil Nadu to our prestigious buyers. Available in an assortment of models, our Gaskets are widely preferred in many industries. We are capable of catering to bulk demands of Spiral Wound Gaskets by our customers. Our quality graded Spiral Wound Gaskets are available at most economical rates and can be delivered to any part of the world. Highlights : Used in varied industries like Petrochemical, Process Industries, Refiners and Steam lines sectors Varied models available like Type R, Type RIR, Type CG, Type CGI, Type HE, Type HE-CG, Type HE-CGI, Type CG-RJ, Type 625 and Type M, MC & MCS

Spiral Wound Gasket

Get Price Quote

Product Description Spiral Wound GasketsConstruction: Special Spring like Metal strips are wound with an Asbestos Filler by a special process to assure a leak proof seal. The sealing is done by the Asbestos Filler and the metal strip provides the spring. This combination of metal and soft asbestos Filler piles compresses to its predetermined thickness under bolting pressure and thereby preventing leakage within the limit of its specified pressure and temperature ranges. With the addition of Centering devices, adapt Spiral Wound Gaskets to use on many types of flanges and closures. Materials: Standard materials are type 304 Stainless steel with white Canadian (Chrysotlie) Asbestos Filler.

Spiral Wound Gasket

Get Price Quote

Spiral wound gasket by spirally winding a preformed metal strip and filler on the outer periphery of metal winding mandrels whose outside diameter form the inner diameter of the gasket and superposed metal and non-metallic windings are continually wound until the required outer diameter is attained.

Spiral wound gaskets

20 Per Piece

Spiral Wound Gasket

10 Per Piece

Spiral wound gaskets

Get Price Quote

spiral wound gaskets metal jacketed gaskets boiler gaskets flange gaskets washers shims cooper gaskets valve gaskets brake liners

Spiral Wound Gasket

Get Price Quote

We are offering spiral wound gasket type I filler with winding strip type ii filler with winding strip & outer ring type iii filler with winding strip & inner ring type iv filler with winding strip, outer & inner ring.

Spiral Wound Gasket

Get Price Quote

Heat exchanger maintenance, heat exchange tube cleaning, oil flushing service

Spiral Wound Gasket

Get Price Quote

non metals, industrial gasket, insulating gaskets, PRE-CUT SHIMS

Spiral wound gaskets

Get Price Quote

Compressed Asbestos Fibre, Rubber Profiles, Rubber Chords, Rubber Linings