Two Motor Seam Welding Machine

Get Price Quote

Hand Operated Spot Welding Machine

Get Price Quote

Portable Integrated Type

Best Deals from Spot Welding Machines

Desktop Laser Spot Welding Machine

1,000,000 - 1,100,000 Per piece

1 Piece (MOQ)

Projection Welding Machine

100,000 - 1,000,000 Per Piece

1 Set(s) (MOQ)

LASER JEWELRY SPOT WELDING

Get Price Quote

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts. Advantages: Very suitable to repair molds in all sizes. The adjustable range of power, pulse width, frequency and spot size is wide. The technical data were adjusted by the controlling bar in the hermetic cavity Easy to operate and high working efficiency Keep on working up to 24 hrs, the performance of the whole machine is very stable Prevent corrosion, the lifespan of the cavity can up to 8-10 years, and the lifespan of the xenon lamp can up to 8 million times. Protection shelter can protect your eyes from the hurt of laser, with a humanistic design, comfortable for working. All data can be adjusted by an intellectualized controller, easy and fast to operate.

Ortho Spot Welder

Get Price Quote

Portable table top, light weight spot welder Feather type finger witch,automatically activates the solid state circuit, releaing the welding energy. Rotary type switch with progressive heat station for welding and auxiliary functions. Turret with one soldering and 4 welding electrode combination. Rocker switch for easy transformation from welding to soldering and vise versa. The carbon electrode specially designed only for soldering. Functions Welding with four welding stations, sharp electrodes both sides for optimum welding. Soldering carbon with flat copper tip. All tips are made of special grade Copper Alloy high density. Technical Features Over load protection fuse 2 amps. Works on 220V AC Current. Output 2.5V AC Current very safe. Insulated AC Power transformer for various Optional Flexible soldering cable Annealing jack Foot switch welding and soldering

Spot Projection Welding Machine

Get Price Quote

We bring forth superior quality pneumatic SAI Spot Projection Welding Machine that are equipped with digital programmable thyristor control. These machines are custom designed for meeting the special needs and requirements of honored customers. Our range can also be customized as per the briefed specifications of the customers.

Die Spotting Machine

Get Price Quote

projection welding machines

Get Price Quote

These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and Rotary movements with PLC could be supplied for fast production. A variety of electrodes and toolings can be fitted to render them suitable for spot welding, simple projection welding, electro-brazing, hot riveting, electro-forging and upsetting.Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high speed automatic operation.These machines are designed and manufactured conforming to the Indian Standard Specification No.IS:4804 Part I and III or as per guidelines of JISC-9303 by a team of highly experienced engineers in welding technology.

Spin Friction Welding Machine

Get Price Quote

Product Introduction : It converts mechanical energy to thermal energy through spin friction at high speed so as to increase the surface temperature of the workpiece to be welded. Pressure is applied after melting to weld the parts together. It is not limited by the workpiece size and material, Compared with other techniques, it can reach a welding strength almost as high as the strength of the plastic body.

Spot Welding Machine

Get Price Quote

HX-DH500 PVC Positioning spot welding machine PVC sheets manual positioning spot welding Adopt bevel positioning, bevel angle adjustable. Hot press method positioning welding Spot welding head can be two or three

Seam Welding Machine

Get Price Quote

Non Woven Spot Welding machine

Get Price Quote

Ultrasonic Spot Welder

Get Price Quote

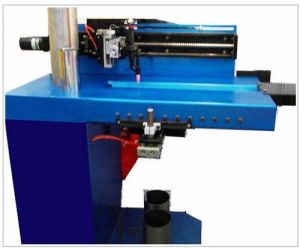

Circumferential Welder

Get Price Quote

We are dedicatedly betrothed in offering a commendable array of Circumferential Welding. Used to perform Circular Weld on boiler etc., our offered Cir- seam is manufactured with leading techniques utilizing best material under the direction of our experts. Along with that, this Cir-seam can be customized as per the need of customers within a committed time frame. This Cir-seam is tested on various parameters in order to make certain its flawlessness.

Spot Welding SPM

700,000 Per Unit

Spot Welding Robot

Get Price Quote

Tespa Robotics an Indian based company provides turnkey solutions for all Robotic and Automation applications introducing contemporary world-class standards in Robotic Cells & Line Automation in a wide spectrum of fields. Tespa Robotics Engineering team serves a range of industries like automotive, Power & energy, consumer goods, food and beverages, pharmaceutical, and more - for all their robot-based automation needs with three Manufacturing facilities in Chennai.

Spot Welding Machine

64,000 Per Units

spot welding

Get Price Quote

Spot Welding We offer ready-to use robot packages for high quality and high performance spot welding. Spot Welding Equipment is specifically designed to be a reliable solution for spot welding applications. All hardware, software and electrical modules you require to complete a function package except gun are included. The components are designed and configured to easily interface with each other.

Spot Welding Robot

Get Price Quote

To meet the stringent quality requirements for welding while ensuring 100% availability and reliability of the individual components and welding robots, controlled optimised cooling of the welding is imperative. Operators must therefore be in a position to quickly and accurately detect any leaks in the cooling system caused by worn electrode caps and other defects.