Vibrating table

The table mounted on mounting springs is vibrated by the unbalance vibro motor mounted at the bottom of the table. Sremag vibratory tables offer a fast efficient and economical method for compacting a wide variety of materials powdery, granular or flaky in boxes, drums or cartons. They are versatile and widely used for industrial applications to package, shock and fatigue test and for densifying refractory blocks, concrete products. They can also be used as shakeouts for some foundry flasks and in concrete block industries. Sremag compaction table are used to settle, compact and consolidate material features: electro flux unbalanced vibrating motor for vertical linear vibration standard vibrators offer adjustable frequency variable forcespeed control is an option heavy duty roller conveyors take any load air spring isolators for lifting mold boxes off the roller conveyor during vibration cycle SREMAG Compaction Table are used to settle, compact and consolidate material Features: Electro Flux Unbalanced Vibrating Motor for vertical linear vibrationStandard vibrators offer adjustable frequencyVariable force/speed control is an optionHeavy duty roller conveyors take any loadAir spring isolators for lifting mold boxes off the roller conveyor during vibration cycle

...more

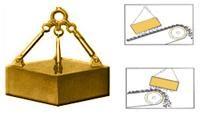

Suspension Magnet

SREMAG Suspension Magnets are designed for installation over conveyors where tramp iron contamination exists and needs to be removed for protection of subsequent processing machinery or providing cleaner product Just suspend it over the conveyor or over the head pulley. When the magnet surface starts to fill up, swing the magnet away from the conveyor and cut the power (electromagnet) or use the convenient wiper arm (permanent magnet) to release the attracted metal Suspension heights up to 10" to 12" are available. Manually cleaned magnets can be supplied with a stripper mechanism. No power consumption, virtually maintenance free. SREMAG Suspension Magnet available is in permanent Magnet and Electro Magnet Electro Suspension Magnet consisting of aluminum or copper wound coils immersed in a transformer oil (for prevention of overheating or shorting) or air- cooled for extreme or dusty environments.

...more

RECTANGULAR ELECTRO LIFTING MAGNET

Sremag magnets mainly used to lift heavy sheets, plates, rounds or squre bars, bundles, billets, ingots and many similar applications, in shipyards, steel miles and foundaries. The magnes makes direct contact with the surface, as a gap of as little as 1 mm can cause a 50% reduction in lifting capacity. These magnets can be used individually or in multiples with different types of suspension systems. the correct ch01se of system depends on the following factors: the stucture and function of the crane. The type of traverse fitted. The shpe and surface of the material to be lifted. THE CORRECT CH01SE OF SYSTEM DEPENDS ON THE FOLLOWING FACTORS: The stucture and function of the crane.The type of traverse fitted.The shpe and surface of the material to be lifted.

...more

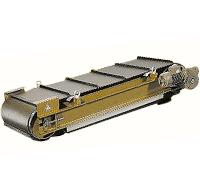

OVER BAND MAGNETIC SEPERATOR

SREMAG Self- Cleaning Separators are designed for installation over conveyors where tramp iron contamination exists and needs to be removed for protection of subsequent processing machinery or providing cleaner product. The self-cleaning type uses a two-pulley design. Parallel self-cleaning magnets are mounted in line with the material flow, while transverse self-cleaning magnets remove the ferrous materials over the side of the conveyor. SREMAG Self - Cleaning Magnet is available in permanent Magnet and Electro Magnet. OverBand Electromagnetic Separatorconsist of a stationary tri-polar design magnet unit, with coils wound in aluminum wire or foil (copper available as an option) dependent on size, and insulated to Class 'H' (or above) temperature specification to receive DC power supply. Magnets can be air or oil cooled, whichever is more suitable for the application. Oil cooled magnets are fitted with expansion tanks to ensure the coil is always immersed in oil.

...more

MAGNETIC HEAD PULL

SREMAG Magnetic Pulley Provide contentious protection against tramp iron Contamination of both large and fine iron particles. As product passes over the head pulley, non-ferrous material is discharged in a normal trajectory. Ferrous metal is attracted to the pulley and remains on the belt until the belt moves away from the pulley falling clear of the product stream. The separation is automatic and continuous. Widely used in Recycling/Processing of aluminum, plastic, glass, wood, and other non- ferrous materials flows including Chemicals, food, grains, textile, ceramic and coal. Metal recovery/separation of screws, nails, fasteners, blanks, wire, chain, tools and various ferrous objects from your product flows. APPLICATIONS:Tramp Metal Removal from Conveyor Systems, Purification and Concentration of Ores, Chemicals and Granular Products. Features Efficient, cost-saving recovery of harmful tramp metal; Super-tough, trouble-free operationExclusive continuous radial pole design grabs long rod-like tramp iron across the pulley faceDevelops especially powerful magnetic field at the center of the belt, where burden is deepestNo DC power supply requiredAll welded body and face construction — no bolts or screws to work looseEasy to install, permanent magnetic Pulley require no maintenance

...more

MAGNETIC GRILL AND DRAWER

SREMAG Grate Magnets provide a high intensity high gradient magnetic field to remove ferrous metals from free- flowing materials. Grate Magnets are available in round, square, and rectangular shapes as per your requirement. It is used in or below hoppers, in closed chutes, floor openings, catch bins, and other locations to protect processing equipment and insure product purity. These grids encased totally in stainless steel. For higher level of protection, double and triple banked grids can be used. All grids are available with either ferrite or powerful rare earth magnets. Magnetic Grates in housing effectively remove ferrous fragments and fines from free-flowing material. Housings are constructed of 12 gauges mild or stainless steel Inside the housing are two or more high intensity Magnetic Grates In Frames. Cleaning of the magnets is easily accomplished by removing the cover plate of the housing and sliding out each magnet assembly.

...more

Magnetic Grill

Sremag grate magnets provide a high intensity high gradient magnetic field to remove ferrous metals from free- flowing materials. Grate magnets are available in round, square, and rectangular shapes as per your requirement. It is used in or below hoppers, in closed chutes, floor openings, catch bins, and other locations to protect processing equipment and insure product purity. These grids encased totally in stainless steel. For higher level of protection, double and triple banked grids can be used. All grids are available with either ferrite or powerful rare earth magnets.

...more

Magnetic Floor Sweeper

Sre mag magnetic floor sweepers are well built and incredibly strong with powerfull magnetism. These sweepers perfect for cleaning metal debris from walkways, garages and yards. Reduce the possibility of costly flat tires or persona! insury and decrease the time needed to clean up scattered ferrous metal material.

...more

MAGNETIC DRUM SEPERATOR

SREMAG Magnetic drum separators offer the highest level of magnetic strength and are appropriate for many different applications, including scrap processing, auto shredding, mining, seggregate, or anywhere large volumes of ferrous metal need to be removed. Drum separators are offered with multiple options including: - Mounting frames - Custom magnetic arcs - Custom designs

...more

magnetic drawer

Sremag grate magnets provide a high intensity high gradient magnetic field to remove ferrous metals from free- flowing materials. Grate magnets are available in round, square, and rectangular shapes as per your requirement. It is used in or below hoppers, in closed chutes, floor openings, catch bins, and other locations to protect processing equipment and insure product purity. These grids encased totally in stainless steel. For higher level of protection, double and triple banked grids can be used. All grids are available with either ferrite or powerful rare earth magnets.

...more

Industrial Magnet Separator

98,000 Per unit

1 unit (MOQ)

Power : 1.5 to 3 Hp

Voltage : 240 V

Capacity : 3 ton

Material : m.s

...more

Gyro Screen Separator

47,000 Per Piece

Material : Iron

Capacity : 60 inch

Gyratory Screen

Sremag gyratory screen motion is the most effective method for screening. The heart of the vibrating screen is its specially designed heavy-duty energy efficiency motor, having un balanced weight at top & bottom end of the shaft rotation of un balanced top weight causes vibration in horizontal plane whereas the rotation of lower weight causes tilt & vibrations in vertical plane. By changing their lead angle, various spiral- screening patterns are obtained to suit different application. Advantages: Low power consumptionVaried range of applicationAccurate separationMinimum screen buildingHigh processing rate per unit area of screen Applications: Food IndustryChemical industryPharmaceuticalsCeramics & PlasticsAbrasives

...more

Electromagnetic Vibratory Feeder

20,000 Per unit

Power : 1 kW

Type : Gravimetric Feeders

Electromagnetic Drum Separator

45,000 Per Piece

Capacity : 5 Ton/Hour

Country of Origin : Made In China

Electro Lifting Magnet

SRE MAG Scrap Lifting Magnets feature the highest lifting capacity. It can handle tonnes of scrap continiuously throughtout the day. It is used in metalworking plants to hoist and transport steel parts, forgings, casting, plates, booms, channels, rods and bars. They save time and effort because they can lift steel more quickly and conveniently than any other mechanical device. With a lifting magnet there is no need to attached and secure and lifting supports and nor is it necessary to block up loads on the floor or to move for mechanical devices. APPLICATIONS:Applied to lifting and transporting magnet conductive materials such as steels and irons in metallurgy industry, mine industry, machinery industry, transporting industry and etc., Features Rugged-all-welded construction with goods moisture-proofing.Strong attraction force and low energy consumption.The energizing coils are designed to improve the electrical property and mechanical property of the energizing coils.Heat-resistent grade of insulating material reaches Grade C with long service life.Simple and convenient installation, operation and maintenance.SRE MAG Scrap lifting magnets TERMINAL BOX is designed to ensure protection whilst in operationand are of double entry type enabling the leads from the coils to be sealed in a separate cavity.The Outsidecable is brought through a gland into this second compartment ensuring no possibility of moisture entering the windings.MAGNETIZING COILS for magnet size up to 900 mm dia is pure annealed wire wound and above these are strip round.The glass insulation of class H standard with fibreglass NOMEX tape forming an interlayer makes coil withstand high temperature.BUMBING PLATES are of high grade manganese steel casting as per IS-276 with heavy ribs for added strength. These are clamped in position by the center and outer poles offering complete protection to the coil. The magnets are suspended with three legged STRING CHAINS made of best quality forged steel termination in a forged ring. A two core cable is provided for connection with the supply and suitable insulated plug and socket ensure easy operation.

...more

Conveyor Magnets

Material : Carbon Steel

Country of Origin : Made in India

Be first to Rate

Rate ThisOpening Hours