Wet High Intensity Magnetic Separators

we, at star trace are the recognized manufacturer, supplier and exporter of wet high intensity magnetic separators (whims). The wet high intensity magnetic separators offered by us are magnetic separation equipment for beneficiating weakly magnetic minerals, and for purifying non-metallic minerals. Star trace professionals have specializes in the field of magnetic separation technology. We have been manufacturing and supplying these wet high intensity magnetic separators since 1983. applications of wet high intensity magnetic separators star trace on vphgms is suitable for processing fine, weakly magnetic minerals, such as hematite, limonite, ilmenite, manganese, wolframite, tantalum-niobium, and etcit is also suitable for removing iron and titanium from non-metallic minerals such as quartz, feldspar, nephline, fluorite, ceramic material, and etcour company vertical ring and pulsating high gradient magnetic separator uses combined force field of magnetism, pulsating fluid and gravity to beneficiate weakly magnetic minerals with the advantages of large beneficial ratio, high recovery, matrix not easy to be blocked and excellent performance about wet high intensity magnetic separators the star trace on-1000, stpl-1250, stpl-1500, stpl-1750, stpl-2000 and stpl-2500 have developedthe maximum feed capacity is up to 120thowing to its unique design and its excellent performance for mineral beneficiation, stpl vphgms has successfully applied in several industries note : technical data and specification subject to change. Special wet high intensity magnetic separator can be made on request, customers have to just send their technical data and application required for our engineers.

...more

Wet Drum Separator-2

Stl is one of the leading manufacturers of ore dressing equipment. The present range of stl process equipment enables us to provide complete packages. wet drum separator constitutes an important part of the product range and are known for advanced engineering design and excellent performance. because of continuous development in separator technology stl can offer a complete line of wet drum magnetic separator to the mining and mineral industries. stl's industrial wet drum separator is offered in sizes of dia.1200 mm and 916mm in length up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishingcleaning applications. Each type can be supplied in single drum or multiple drum stages of taconite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent ceramic magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance. stl's magnetic wet separator dia 916 x 300 mm is the smallest full-scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, countercurrent and counter rotation versions. stl's magnetic wet separator for laboratory use has drum dimensions dia. 600 x 285 mm and dia. 200 x 100 mm and are suitable for batch or continuous testing. The test results from the stl laboratory separators correspond closely to those obtained in full-scale operation. stl's magnetic wet separators have been developed in close cooperation with the swedish mining industry for treatment of magnetite. Aprime consideration in its advanced engineering design has been high capacity, improved metallurgical performance and highest availability. The separator is constructed as a separate unit consisting of drum with magnet yoke, tank and drive package, all mounted on a heavy-duty frame. The design of the frame allows any number of units to be connected in series as multi-stage installation. This design offers a flexible flow sheet layout. the drum shell is made of non-magnetic stainless steel with abrasion-resistant wear cover and sealed heads of cast rigid aluminum alloy. The drum shaft runs in spherical, self-aligning antifriction bearings. adjustment of magnet yoke and drum the magnet yoke is mounted on the stationary drum shaft and its position can 0 be adjusted (+-35 ) by a lever at the end of the drum shaft to optimize running conditions in accordance with tank design and type of ore. The gap between tank and drum, which determines the pulp flow speed, can be adjusted vertically by shims inserted under the bearing housing and shaft support. Horizontal adjustment is by slotted holes. drive unit the standard drive train consists of a shaft end mounted torque arm speed reducer outside the tank with v-belt pulley driven from a standard electric motor. This arrangement provides a smooth protected transmission and has several advantages compared to chain drives. Also other driven arrangements can be supplied. the v-belt drive is protected by a steel guard. As an alternative the separator drive unit can be supplied with an easily removable fiberglass cover. These covers protect the entire drive unit and motor, with opening for lubrication maintenance and inspections. the steel v-belt guard is preferred for users in extreme climatic conditions, e.g. Tropical and subtropical. feed and discharge box the feed box is designed for high capacities with a uniform distribution of pulp over the full length of the drum. Removable tramp screens can be provided as an option. the discharge box is bolted to the heavy-duty frame and designed to give a smooth and easy discharge of the concentrate. Wear surfaces are typically rubber-lined. iron recovery a series of investigations have been made to study the effect of magnetic field strength on feed rate and iron recovery. it is evident from the results shown on the diagram to the left how the capacity and recovery figures increase at higher field strength. The studies are made on dia.916mm separator fed with a magnetite ore ground to 75% minus 0.044mm (325 meshes) and separated at 30% solids by weight. the diagram to the right shows the importance of correct tank design with respect to particle size. as shown increased magnetic field strength, gives decreased relative iron losses in the tails for finer fractions. It also proves that the countercurrent tank configuration produces a better recovery than the concurrent type in the fine particle range at the same magnetic field strength. For coarser fractions, the concurrent type is superior. influence of different drum diameters for many years, drum diameters 600mm, 760 mm and later on 916 mm dominated the sales of wet low intensity magnetic separators. realized the advantages of the larger drum diameter and was first to introduce the 1200mm diameter drum. The results from actual operations confirm the vast improvements in performance and capacity with 1200mm drums. the feed to the separators consists of partially martisied magnetite ore ground to 75% minus 0.044mm (325 meshes) and the purpose was to produce a concentrate containing less than 1% sio2. a comparative study was also made using different drum diameters but with the same magnetic field strength rating 850 gauss. The curves shown (right) are a summary of this study. Another advantage worth noting with increased drum diameter is higher concentrate densities and grade. tank configurations in the concurrent separator, the product enters the feed box from which it is uniformly distributed over the full length of the drum. The pulp passes over a weir in the tank, which directs flow against the drum, where upon the magnetic particles immediately, are attracted to the drum. The concentrate is carried forward by the drum and passes through a gap where it is dewatered before leaving the separator. The tailings are discharged through adjustable bottom valves. for best separation results feed pulp density should be 35- 45% by weight solids. the pulp level must be kept constant and approximately 25mm above the lower edge of the drum. This level is adjusted with the bottom valves and is reached when pulp overflows the tank side weirs. The standard stl concurrent separators is capable of handling material with particle sizes up to 6mm special tanks can be supplied for coarser material. the operation of the countercurrent separator differs from that concurrent type in that the tailings are forced to travel in the opposite direction to the rotation of the drum. extra water can be added through specially designed jet pipes, by which sedimentation of coarser particles is avoided. the stl countercurrent separator can handle fluctuating flows within wide limits. Best operating results are obtained at about 30% solids by weight. This type of separator can handle particle size up to 0.8mm (20 mesh). Adjustment of pulp level is not required. the counter rotating separator is recommended for applications where recovery is more important than grade. The pulp flows in opposite direction to the drum rotation and the extended magnet angle provides an extra long pick-up zone for maximum recovery. the particle size handled can be up to 3-4mm (5mesh). The best operating performance is obtained with pulp containing 30 - 40% solids by weight. a special type of separator is available for dense media recovery, requiring ability to treat dilute pulps with low content of very fine magnetic particle at extremely high recoveries. The dense media recovery separator has a modified tank of concurrent type with an extra long pick-up zone. A specially designed high gradient assembly is recommended for treatment of very dilute media. magnetic field strength the magnetic systems consist of ceramic strontium ferrite magnets and are designed to produce highest flux, gradient and flux patterns to match each tank configuration. the magnet systems have the highest field strength in the pick - up zone, and gradually decreasing strength in the transport and dewatering zones. above are shown typical field strength charts for stl magnetic wet separators dia. 1200mm. application guidelines the capacity varies considerably depending on metallurgical criteria. Most important variables are magnetic susceptibility characteristics of the magnetic particles, degree of liberation and size of the feed. mechanical features of the separator as tank design, magnet system and drum diameter do of course affect the capacity. The following capacity figures can be used as guidelines for stl magnetic wet separators in iron ore processing.

...more

Wet Drum Separator-1

Stl is one of the leading manufacturers of ore dressing equipment. The present range of stl process equipment enables us to provide complete packages. wet drum separator constitutes an important part of the product range and are known for advanced engineering design and excellent performance. because of continuous development in separator technology stl can offer a complete line of wet drum magnetic separator to the mining and mineral industries. stl's industrial wet drum separator is offered in sizes of dia.1200 mm and 916mm in length up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishingcleaning applications. Each type can be supplied in single drum or multiple drum stages of taconite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent ceramic magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance. stl's magnetic wet separator dia 916 x 300 mm is the smallest full-scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, countercurrent and counter rotation versions. stl's magnetic wet separator for laboratory use has drum dimensions dia. 600 x 285 mm and dia. 200 x 100 mm and are suitable for batch or continuous testing. The test results from the stl laboratory separators correspond closely to those obtained in full-scale operation. stl's magnetic wet separators have been developed in close cooperation with the swedish mining industry for treatment of magnetite. Aprime consideration in its advanced engineering design has been high capacity, improved metallurgical performance and highest availability. The separator is constructed as a separate unit consisting of drum with magnet yoke, tank and drive package, all mounted on a heavy-duty frame. The design of the frame allows any number of units to be connected in series as multi-stage installation. This design offers a flexible flow sheet layout. the drum shell is made of non-magnetic stainless steel with abrasion-resistant wear cover and sealed heads of cast rigid aluminum alloy. The drum shaft runs in spherical, self-aligning antifriction bearings. adjustment of magnet yoke and drum the magnet yoke is mounted on the stationary drum shaft and its position can 0 be adjusted (+-35 ) by a lever at the end of the drum shaft to optimize running conditions in accordance with tank design and type of ore. The gap between tank and drum, which determines the pulp flow speed, can be adjusted vertically by shims inserted under the bearing housing and shaft support. Horizontal adjustment is by slotted holes. drive unit the standard drive train consists of a shaft end mounted torque arm speed reducer outside the tank with v-belt pulley driven from a standard electric motor. This arrangement provides a smooth protected transmission and has several advantages compared to chain drives. Also other driven arrangements can be supplied. the v-belt drive is protected by a steel guard. As an alternative the separator drive unit can be supplied with an easily removable fiberglass cover. These covers protect the entire drive unit and motor, with opening for lubrication maintenance and inspections. the steel v-belt guard is preferred for users in extreme climatic conditions, e.g. Tropical and subtropical. feed and discharge box the feed box is designed for high capacities with a uniform distribution of pulp over the full length of the drum. Removable tramp screens can be provided as an option. the discharge box is bolted to the heavy-duty frame and designed to give a smooth and easy discharge of the concentrate. Wear surfaces are typically rubber-lined. iron recovery a series of investigations have been made to study the effect of magnetic field strength on feed rate and iron recovery. it is evident from the results shown on the diagram to the left how the capacity and recovery figures increase at higher field strength. The studies are made on dia.916mm separator fed with a magnetite ore ground to 75% minus 0.044mm (325 meshes) and separated at 30% solids by weight. the diagram to the right shows the importance of correct tank design with respect to particle size. as shown increased magnetic field strength, gives decreased relative iron losses in the tails for finer fractions. It also proves that the countercurrent tank configuration produces a better recovery than the concurrent type in the fine particle range at the same magnetic field strength. For coarser fractions, the concurrent type is superior. influence of different drum diameters for many years, drum diameters 600mm, 760 mm and later on 916 mm dominated the sales of wet low intensity magnetic separators. realized the advantages of the larger drum diameter and was first to introduce the 1200mm diameter drum. The results from actual operations confirm the vast improvements in performance and capacity with 1200mm drums. the feed to the separators consists of partially martisied magnetite ore ground to 75% minus 0.044mm (325 meshes) and the purpose was to produce a concentrate containing less than 1% sio2. a comparative study was also made using different drum diameters but with the same magnetic field strength rating 850 gauss. The curves shown (right) are a summary of this study. Another advantage worth noting with increased drum diameter is higher concentrate densities and grade. tank configurations in the concurrent separator, the product enters the feed box from which it is uniformly distributed over the full length of the drum. The pulp passes over a weir in the tank, which directs flow against the drum, where upon the magnetic particles immediately, are attracted to the drum. The concentrate is carried forward by the drum and passes through a gap where it is dewatered before leaving the separator. The tailings are discharged through adjustable bottom valves. for best separation results feed pulp density should be 35- 45% by weight solids. the pulp level must be kept constant and approximately 25mm above the lower edge of the drum. This level is adjusted with the bottom valves and is reached when pulp overflows the tank side weirs. The standard stl concurrent separators is capable of handling material with particle sizes up to 6mm special tanks can be supplied for coarser material. the operation of the countercurrent separator differs from that concurrent type in that the tailings are forced to travel in the opposite direction to the rotation of the drum. extra water can be added through specially designed jet pipes, by which sedimentation of coarser particles is avoided. the stl countercurrent separator can handle fluctuating flows within wide limits. Best operating results are obtained at about 30% solids by weight. This type of separator can handle particle size up to 0.8mm (20 mesh). Adjustment of pulp level is not required. the counter rotating separator is recommended for applications where recovery is more important than grade. The pulp flows in opposite direction to the drum rotation and the extended magnet angle provides an extra long pick-up zone for maximum recovery. the particle size handled can be up to 3-4mm (5mesh). The best operating performance is obtained with pulp containing 30 - 40% solids by weight. a special type of separator is available for dense media recovery, requiring ability to treat dilute pulps with low content of very fine magnetic particle at extremely high recoveries. The dense media recovery separator has a modified tank of concurrent type with an extra long pick-up zone. A specially designed high gradient assembly is recommended for treatment of very dilute media. magnetic field strength the magnetic systems consist of ceramic strontium ferrite magnets and are designed to produce highest flux, gradient and flux patterns to match each tank configuration. the magnet systems have the highest field strength in the pick - up zone, and gradually decreasing strength in the transport and dewatering zones. above are shown typical field strength charts for stl magnetic wet separators dia. 1200mm. application guidelines the capacity varies considerably depending on metallurgical criteria. Most important variables are magnetic susceptibility characteristics of the magnetic particles, degree of liberation and size of the feed. mechanical features of the separator as tank design, magnet system and drum diameter do of course affect the capacity. The following capacity figures can be used as guidelines for stl magnetic wet separators in iron ore processing.

...more

Wet Drum Magnetic Separators

we are one of the leading manufacturers, exporters, and suppliers of wet drum magnetic separators. The wet drum magnetic separators are process equipment that is known for advanced engineering design and excellent performance. We manufacture a wide range of wet drum magnetic separators to mining and mineral industries. Avail the wet drum magnetic separators from us at market leading price. product models and sizes stl's wet permanent magnetic separators are offered in sizes of dia.1200 mm and 916mm in lengths of up to 3000mmthree basic separator designs are available for cobbing, roughing and finishingcleaning applicationseach type can be supplied in single drum or multiple drum stages of taconite or magnetite and also for recovery for magnetic medium in dense media plantsthe stationary magnet yoke is an assembly of strontium-ferrite permanent ceramic magnetsthe rotating drum is available with optional rubber or stainless steel coversthe magnetic flux pattern will match the tank configuration for optimum performancestl's magnetic wet separator dia 916 x 300 mm is the smallest full scale separator in the 916 series and is primarily used for pilot plant teststhe separator can be delivered in concurrent, countercurrent and counter rotation versionsstl's magnetic wet separator for laboratory use has drum dimensions dia. 600 x 285 mm and dia.200 x 100 mm and are suitable for batch or continuous testingthe separators correspond closely to those obtained in full scale operationpilot unit dia. 916 x 300mm. Leftstl's magnetic wet separators have been developed in close cooperation with the swedish mining industry for treatment of magnetitea prime consideration in its advanced engineering design has been high capacity, improved metallurgical performance and highest availabilitythe separator is constructed as a separate unit consisting of drum with magnet yoke, tank and drive package, all mounted on a heavy-duty framethe design of the frame allows any number of units to be connected in series as multi-stage installationthis design offers a flexible flow sheet layoutthe drum shell is made of non-magnetic stainless steel with abrasion-resistant wear cover and sealed heads of cast rigid aluminum alloythe drum shaft runs in spherical, self-aligning antifriction bearings adjustment of magnet yoke and drum the magnet yoke is mounted on the stationary drum shaft and its position can be adjusted (+-35) by a lever at the end of the drum shaft to optimize running conditions in accordance with tank design and type of orethe gap between tank and drum, which determines the pulp flow speed, can be adjusted vertically by shims inserted under the bearing housing and shaft supporthorizontal adjustment is by slotted holes drive unit the standard drive train consists of a shaft end mounted torque arm speed reducer outside the tank with v-belt pulley driven from a standard electric motorthis arrangement provides a smooth protected transmission and has several advantages compared to chain drivesalso other drive arrangements can be suppliedthe v-belt drive is protected by a steel guardas an alternative the separator drive unit can be supplied with an easily removable fiberglass coverthese covers protect the entire drive unit and motor, with opening for lubrication maintenance and inspectionsthe steel v-belt guard is preferred for users in extreme climatic conditions, e.g. Tropical and subtropical.

...more

Wet Drum Magnetic Separator

We are celebrated Manufacturer, Exporter and Supplier of Wet Drum Magnetic Separator. Wet Drum Magnetic Separators offered by us, are available in the diameters of 1200 mm and 916 mm with lengths up to 3000 mm. This Wet Drum Magnetic Separator offers enhanced metallurgical performance. It has components such as tank, drum with magnet yoke, and drive package which make it efficient. Also, these Wet Drum Magnetic Separators are available with us at competitive prices. STL's wet permanent magnetic separators are offered in sizes of dia.1200 mm and 916mm in Lengths of up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishing/cleaning applications. Each type can be supplied in single drum or multiple drum stages of taco nite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent ceramic magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance. STL's magnetic wet separator dia 916 x 300 mm is the smallest full scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, counter current and counter rotation versions. STL's magnetic wet separator for laboratory use have drum dimensions dia. 600 x 285 mm and dia. 200 x 100 mm and are suitable for batch or continuous testing. The test results from the STL laboratory separators correspond closely to those obtained in full scale operation. STL's magnetic wet separators have been developed in close cooperation with the Swedish mining industry for treatment of magnetite. A prime consideration in its advanced engineering design has been high capacity, improved metallurgical performance and highest availability. The separator is constructed as a separate unit consisting of drum with magnet yoke, tank and drive package, all mounted on a heavy-duty frame. The design of the frame allows any number of units to be connected in series as multi-stage installation. This design offers a flexible flow sheet layout.

...more

Vibro Separator

We are offering vibro separator. Introduction: star trace vibro separator is a unique particle size gradable separator designed for greater capacity per meter square of screening area & over size material discharge with relatively much less percentage fines than other screening machines. Our company has been a leader in manufacturing and supplying a vast variety of screen separators to various industries across the country. We offer horizontal vibro separator and circular vibro separator which come with many special features. Our screen separators are known for their high performance, innovative designs, and affordable prices making them extremely popular among customers working principle: the motivation is through a unbalanced motor with a double extended shaft, fitted at both ends with eccentric weights .the top weight on the motor shaft rotates in a plane close to the center of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane, which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the center of mass creating tilt on the screen giving vibration in vertical and tangential plane. Increasing the vertical component of motion, this promotes turnover of material on the screen surface helping maximum quantity of undersize material to pass through the screen. Rugged springs placed over the circular motor base amplifies the vibration. The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weight creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery. Increasing the top eccentric mass, increases the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the centre of mass, creating tilt on the screen, giving vibration in vertical & tangential planes. Increasing the vertical component of motion, this promotes turnover of material on the screen surface helping maximum quantity of undersize material to pass through the screen. The vertical motion also minimizes blinding of screen by "near size" particles. The tangential component of motion is controlled by the angle of lead given to bottom weights with relation to top weight. Variation in lead angle controlled the spiral pattern of material travel over the screen cloth. Speed & flow pattern of material travel over the screen cloth can be set by the operator for maximum throughout & screening efficiency for any screen able product, wet or dry, coarse or fine, heavy or light, hot or cold. Typical material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet. Applications mineral processing ceramic food & beverages abrasive industries chemical pulp & paper rubber industry pharmaceutical animal feed effluent & waste water treatment paint & pigments sand & gravel petroleum sugar & syrup benefits the following are the benefits of gyratory screen are: low power consumption varied range of applications high processing rate per unit area of screen accurate separation minimum screen building screening up to 200 mesh ball tray for anti blinding modular design to yield up to 8 predetermined fractions dust-free and noiseless processing within closed circuit can be achieved

...more

Vibratory Motors

We are offering vibratory motors. Introduction: star trace vibratory motors are robust, reliable, high loadable, quiet running and require no maintenance. Star trace vibratory motors are totally enclosed 3phase, squirrel cage induction motors with adjustable, eccentric weights mounted at both ends of the shaft, to set up vibrations during rotation. The design of shaft and the selection of bearings has been carefully done to withstand heavy radial loads. Uses: plastics food petro-chemical processpackaging mining cement power stations technical data: centrifugal force range : from 42 to 14250n operating torque range suitable for vibrating units : from 3.6 to 3600 kgs. Working weight range : from 1 to 6000 kgs. Power connection : from 3phase current with 50hz 415v a.c. Rated consumption : 0.1 to 10kw. Ambient temperature : upto 60 deg.c degree of protection : ip 65as in din 40 050, p.2 or ip 55as in din iec 34, part 5. Insulation class : f class. Features : the following are the features of vibratory motor: increased efficiency. Enhanced reliability & low maintenance. Rugged construction for tough environment. Cylindrical roller bearing. Prelubricated for long life. Robust design, body made from high grade c.i. Casting totally dust proof air cooled design. Can operate in dusty environments. Winding f-class insulated. Impervious to dust, moisture & vibrations. Vibration force adjustable from zero to maximum by adjusting position of unbalance weights. Applications : these motors are used in various material handling equipment such as vibrating screens, conveyors and feeder. They are also used on hoppers, silos to prevent congestion of material flow. Foundry shake-outs and compacting machines use these motors for fast and efficient operation. Their special essential characteristics are: one of two lifting lugs. Absolutely secure centrifugal mounting. Quality-tested components, each motor tested under load. Reliable starting by means of a high-powdered starting torque. Permanent and well legible setting marketing of the unbalanced weights. Vibration-proof joining through the considerable tensility of the mounting screws. Dust-tight and water-tight through a sealing covering with special circular rubber washer. Universal mounting facilities through an optimum choice of inter spacing in the base mounting. Embedded in high-quality impregnating resin vibration-proof winding, insensitivity to damp and dust. Generously dimensioned cylindrical roller bearing, self lubricating maintenance-free, long life expectancy.

...more

Vibratory Motor

Vibratory Motor that we offer is acclaimed for its robust construction, high loadable, zero noise and low maintenance. Our Vibratory Motor is totally enclosed 3Phase, squirrel cage induction motor with adjustable eccentric weights mounted at both ends of the shaft to set up vibrations during rotation. The design of the shaft and the selection of the bearings are specifically done in order to make it withstand heavy radial loads. The Vibratory Motor is widely used in power stations, petro-chemical, food, plastics, mining, cement, process/packaging, etc. Technical Data Centrifugal Force Range : From 42 to 14250NOperating torque range suitable for vibrating units : From 3.6 to 3600 KgsWorking Weight Range : From 1 to 6000 Kgs. Power Connection : From 3Phase current with 50 Hz 415V A.C.Rated consumption : 0.1 to 10KWAmbient Temperature : Upto 60 deg.CDegree of Protection : IP 65as in DIN 40 050, P.2 OR IP 55as in DIN IEC 34, Part 5Insulation Class : F class Features Increased efficiency. Enhanced reliability & low maintenance. Rugged construction for tough environment. Cylindrical roller bearing. Prelubricated for long life. Robust design, body made from high grade C.I. casting Totally dust proof air cooled design. Can operate in dusty environments. Winding F-Class insulated. Impervious to dust, moisture & vibrations. Vibration force adjustable from zero to maximum by adjusting position of unbalance weights Applications These motors are used in various material handling equipment such as vibrating screens, conveyors and feeder. They are also used on hoppers, silos to prevent congestion of material flow. Foundry shake-outs and compacting machines use these motors for fast and efficient operation. Their Special Essential Characteristics are : One of two lifting lugs. Absolutely secure centrifugal mounting. Quality-tested components, each motor tested under load. Reliable starting by means of a high-powdered starting torque. Permanent and well legible setting marketing of the unbalanced weights. Vibration-proof joining through the considerable Tensility of the mounting screws. Dust-tight and water-tight through a sealing covering with special circular rubber washer. Universal mounting facilities through an optimum choice of inter spacing in the base mounting. Embedded in high-quality impregnating resin vibration-proof winding, insensitivity to damp and dust. Generously dimensioned cylindrical roller bearing, self lubricating maintenance-free, long life expectancy

...more

Vibratory Furnace Charger

Our Vibratory Furnace Charger offers precise charge enhancement capabilities, automated batch control and optional scrap drying. Vibratory Furnace Charger that we provide is specifically designed so as to control the fumes and direct the charge into the center of the furnace. Vibratory Furnace Charger can also be motorized so as to move it forward, backward, up, down, or transversely. Additionally, in some special applications our Vibratory Furnace Charger can be entirely radio controlled making it independent of rails. Operating Principle The required amount of scrap metal is loaded into the storage hopper at the loading point. The trolley then carries the vibrating feeder along with the storage hopper to the furnace charging point. Here, the vibrating feeder is energized and the material is effectively discharged into the furnace as per the required capacity. As the metal is melted down, fresh batch of metal can be fed into the furnace thereby keeping the furnace full. The capacity of the vibrating feeder can be varied by varying the amplitude of variations. The amplitude of vibrations can be varied by adjusting the position of centrifugal weights or by using a variable frequency drive (optional). A control panel specially designed to suit individual client requirement depending on the sequence of operations required is provided. Advantages Very fast as compared to manual charging of furnace thereby enabling optimum use of the melting system. Extremely controlled charging of material into the furnace. Prevents damage to the furnace lining since the material is properly guided into the furnace so as to avoid the material from hitting the furnace walls. No direct exposure of manpower to the furnace thereby preventing dangerous accidents due to metal splash (since the operator can carry out the operations at a very safe distance). Minimum heat loss of the furnace since the charging process can be maintained continuously at the required rate Features Patented charge feeder nosepiece expands to prevent jams, fits tight to furnace hood to contain fumes and any potential splashback, and directs charge into center of furnace to reduce furnace damage. Noise reduction vibrating feeder troughs for quiet loading and unloading. Heavy duty vibratory feeder designed for 24/7, 365 operation with little maintenance requirements reduces your planned downtime. Two-mass, natural frequency charge feeder design requires very little energy to operate, reducing your energy costs. Variable speed material discharge

...more

Vibratory Finishing Machine

Vibratory Finishing Machine, offered by us, is ideal for process like de-scaling, de-burring, polishing, surface improvement, edge reducing as well as pre-plating finishing all types of components that includes fully machined parts in metals & plastics. Our Vibratory Finishing Machine is widely applied to instruments, metal parts, apparatus, standard parts, sewing machines, auto parts, bearings, non-ferrous metal products, etc. Working Principle The vibratory finishing machine for metal working has a ring chamber to hold abrasives and work pieces. When the machine is working, it makes three-d high frequency vibration. The grinding stones and the work pieces are rolling spirally forward and they are grinding each other during the rolling. This makes the work pieces de-burred, chamfered, polished and clean, to replace the traditional cloth-wheel polishing, the vibratory finishing machine for metal working can save a lot of spending on manpower, and lower the cost of production. It can also be matched up with mass production, improve and stabilize the quality of the products. Applications Mainly applied to metal parts, standard parts, apparatus, instruments, bicycles, sewing machines, hydraulic parts, bearings, auto parts, plastics, ceramics, non-ferrous metal products and parts industry de burring parts to rust, polishing rough, medium polished, fine polishing, bright polishing, especially for special-shaped part of the surface finishing are superior to specific functions, as it after finishing the parts.

...more

Vibration Meter

Vibration Meter that we offer is a handheld analog instrument that is specifically designed for a large variety of vibration measurement applications. Our Vibration Meter is able to indicate True RMS vibration displacement. Vibration Meter, provided by us, is appreciated for its easy usage, high efficiency and accurate measurement. Our Vibration Meter is suitable for different vibration measuring needs like for turbines, fans, generators, blowers, pumps, motors, alternators, bearings, etc. Vibration Measurement Vibration measurement on rotating machinery is normally done for two major applications : Quality Control, and Predictive Breakdown Maintenance In addition to the commonly understood QC application on motors, generators, blowers, or a host of rotating or reciprocating machinery, vibration is increasingly being used with enormous benefits for the second application : Predictive Breakdown maintenance.In continuously running plant, where sudden breakdowns can be disastrous, vibration is an immensely important indicator for planning an effective predictive maintenance strategy. Periodically observed vibration readings at strategic points on the machine will indicate a rising trend well before a breakdown occurs. This signals the need for taking timely corrective action. This will drastically reduce sudden and unexpected machinery failures, thus resulting in substantial savings in downtime. Features Hand- Held unit for General Purpose Vibration Measurement. Accelerometer type sensor. Touch type membrane switch panel. RMS Velocity, Pk-Pk Displacement. Portable and compact unit. Economical, easy to use. Analog Display Surface-mount technology for high reliability. Rugged, suitable for industrial use

...more

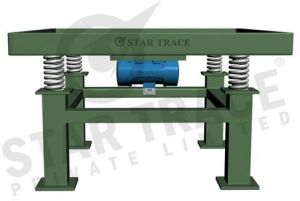

Vibrating Tables

our premium vibrating tables are designed to settle and compact dry bulk materials in various types of containers. The application of these vibrating tables offers either a sizable increase in the net weight of the container or reduction in the container size with succeeding savings in shipping and storage space. These vibrating tables come in two types namely electromagnetic & electromechanical. The choice of the proper type and model depends upon the application, characteristics of the materials or objects being handled, its reaction to vibration, the maximum weight to be handled and the type of container. Our vibrating tables are presented in five models with maximum capacities up to 6 tones. features the drives are totally enclosed, dust tight and splash proofsturdily constructedextra-heavy duty bearings for extended service life applications settle 2,000 kg coils of strip steel to obtain alignment before transportation and storageeffective for handling a wide array of metal parts like nuts, bolts and rivets.

...more

Vibrating Table

Vibrating Table that we present is designed to settle down the dry bulk materials in different kinds of containers. The application of a Vibrating Table either provides a sizeable increase in the net weight of the container or reduces the container size with consequent savings in shipping and storage space. We make available two types of Vibrating Table, namely Electromagnetic & Electromechanical. Vibrating Table is widely used in various industrial applications like construction, foundries, concrete, chemical and bulk materials, instruments and scientific apparatus, etc. Further, the selection of the appropriate Vibrating Table depends on the application, characteristics of the material or objects being handled, its reaction to vibration, the maximum weight to be handled and the type of container. Working Principle Unbalance motors make the table top to oscillate. An oscillation insulating elastic suspension connects the table top and table bottom part. By adjusting the unbalances on the unbalance motors during standstill the oscillation amplitude can be changed. If an electric control with frequency inverter is being used the vibration frequency can be changed even during operation. Both parameter have influence on the vibration intensity and allow an adaption to the different scopes. Industrial Uses Steel Foundries Concrete Chemical and Bulk Materials Food ProcessingInstruments and Scientific Apparatus Plastics Aerospace Construction Features User friendly. Can hold up to 200lbs. High operational efficiency. Low power consumption. Low on maintenance. Noiseless. Uniform Vibration. Vibration stays on the top plate. Trouble free & noiseless operation. Properly fitted with the motors and other pars to ensure smooth functioning Applications Used for compaction, detachment and aeration of bulk materials. Used for testing of welded joints in automobile industry and delicate joints in electronic industry. Used for effective packing of fluffy and difficult to handle powder in chemical and pharmaceutical industry. Used for proper flow of powder in dies and moulds to get perfect moulded parts Benefits Put more material into smaller containers. Ship less air. Reduce overflow and spillover waste at filling stations. Perform fatigue testing. Top quality, fastest delivery

...more

Vibrating Screen Separators

we are the major vibrating screen separators manufacturer, exporter and supplier in chennai, tamil nadu. Vibrating screen separators are exclusive particle size gradable separators made for greater capacity per meter square of screening area & huge material discharge with relatively much less percentage fines than other screening machines. used in food & beverages effluent & wasteceramic animal feedmineral processing pharmaceuticalabrasive industries water treatment working principle the top weight on the motor shaft rotates in a plane close to the center of the mass of assembly. Rotation of the top eccentric weight creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery. Increasing the top eccentric mass, increases the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the center of mass, creating tilt on the screen, giving vibration in vertical & tangential planes. Increasing the vertical component of motion, this promotes turnover of material on the screen surface helping maximum quantity of under size material to pass through the screen. The vertical motion also minimizes blinding of screen by “near size” particles. The tangential component of motion is controlled by the angle of lead given to bottom weights with relation to top weight. variation in lead angle controlled the spiral pattern of material travel over the screen cloth. Speed & flow pattern of material travel over the screen cloth can be set by the operator for maximum throughout & screening efficiency for any screen able product- wet or dry, coarse or fine, heavy or light, hot or cold. Typical material passes rapidly through the screen during its travel to the periphery. The oversize material get continuously discharged through a tangential outlet.

...more

Vibrating Screen ( Other Product For Gold)

We are offering vibrating screen ( other product for gold). vibrating screen :(other product for gold) the type universal vibro screen is a new generation vibratory screening machine characterized by low profile, efficient protection of support structure from vibrating masses and virtually noiseless operation. The various versions of these vibro screens permit its use for: wet and dry screening coarse and fine separations and are widely used in steel mills mineral beneficiation plants chemical mining food and fertilizer industries coal preparation plants and many others. The standard range of screens from 300x900mm to 3000x9000mm in single and multi deck configuration.

...more

Vibrating Machine

Our Vibrating Machine is manufactured using the most advanced techniques as well as manufacturing equipment. Vibrating Machine that we offer is convenient in usage and known for providing excellent performance for longer term. Our Vibrating Machine is easily cast by using a tamping bar or a vibrating table. Vibrating Machine is widely used for the preparation of the mortar cubes as well as for determining the compression strength of rapid and ordinary hardening portland cement, portland bleast furnace cement, low heat portland cement and high alumina cements.

...more

Vibrating Grizzly Feeder

The Grizzly Feeder is suitable to feed primary jaw crushers, selecting the large sizes which require primary crushing, the smaller sizes, and any fines which must be eventually rejected. The Grizzly vibro feeder consists of a very large vibrating body made of thick plate, with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder which may either be placed on a steel or concrete base rest on springs.

...more

Vibrating Feeders

Electromagnetic Vibrating Feeders provided by us are high frequency reciprocating machine capable of conveying bulk materials between various processes. These Electromagnetic Vibrating Feeders can handle all types of material irrespective of their nature like hot, damp etc. These can be used across various processes like sprinkling, weighing, mixing etc. (Electromagnetic Vibrating Feeders) These are supplied with base mounted, over hanging and combined single magnet drive. These can also be availed with dual twin magnet drives and with multiple drives to be served as vibrating conveyors. The drive unit is located below the tray consisting of two sets of leaf springs connected to mounting bracket. (Electromagnetic Vibrating Feeders) When magnetic coil is energized it gives horizontal vibrations to the tray to en cure free, smooth, volumetric flow to the material. (Electromagnetic Vibrating Feeders)These can be availed in various trough sizes as per is:8723-1978 standard.

...more

Vibrating Feed Furnace Charger

Type : Vibratory Furnace Charger

Color : Brown, Grey, Light White, White

Voltage : 110V, 220V, 380V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power Source : Electric

Warranty : 2 Yrs, 3 Yrs, 6 Months 1 Yr

...more

vibrating equipment

Grown with the years of business expertise, we manufacture a wide range of Vibrating Equipments for heavy machinery work assist (Vibrating Equipment). Our manufacturing unit follows the quality of reliability to provide the highly loadable quiet running and low cost maintenance facility. Our Vibrating Equipments are fabricated with high quality raw materials that are procured from the noted vendors. We provide many options in this section such as: Vibratory Motor Vibratory Feeder Vibro Screen Bin Vibrator Piston Impactor Screen Separator Electro Mechanical Feeder Vibrating Grizzly Screen Feeders Ball Vibrator Circular Motion Inclined Screens Tubular Feeders/Conveyors Vibration Meter Vibro Energy Finishing Machine Dewatering Screen Test Sieve Shaker Tandem Vibratory Road Rollers Vibrating Table Electro Magnetic Vibrator Vibrating Tumbler Vibrating Shifter Linear Motion Screen Extra Heavy Duty Vibrating Feeders

...more

Vibrating Conveyors

Being one of the most prominent Manufacturers, Exporters and Suppliers in Chennai, Tamil Nadu, we produce the high-end Vibrating Conveyer with latest technology. This Vibrating Conveyer is characterized by the low horsepower essential and high volumes of material. We are providing this Vibrating Conveyer with a flexible balanced design which facilitates exceedingly polish conveyor to handle it gently. Advantages Of Vibrating Conveyor Levels and orients material as it is conveyed, reducing surges to downstream equipmentMoves high volumes of material with low horsepower requirementsCounter balanced design provides an extremely smooth running conveyor with reduced foundation and support structure requirementsBuilt in 10 foot long sections which are bolted together to make up a conveyor of the required lengthOdd length sections are available for use at the ends of the conveyor when the length is not a multiple of 10 feet

...more

Ultrasonic Screen Separator

We bring forth highly efficient Ultrasonic Screen Separator for our valued customers. With large process capacity, Ultrasonic Screen Separator has screening efficiency of up to 80%. Our valued customers can avail Ultrasonic Screen Separator in different specifications as per their requirement. Benefits Screen frame support by rubber spring suspension, low noise, power consumption, dynamic load device is small, so no special requirements on the installed base The use of force distribution to the ore pulp, the pulp flow rate to reduce screen surface to extend screen life while allowing the pulp evenly spread on the screen. Surface, helps to improve the efficiency of processing and screening. Multiple parallel, small occupancy, it can achieve maximum parallel rd, extend the original multi-feed principle Dual vibrator configuration linear vibration with patented technology recycling pulp, the feed material of fines grade Frequency design, effective control of particle size screening, more rational use of mesh grading Spray corrosion resistance, surface treatment equipment, effectively extend equipment life, reduce the amount of equipment maintenance Configuration high quality, high opening rate, long life of proprietary products-anti clogging polyurethane mesh (fine mesh of 0.1mm), to ensure the lowest production costs Longer screening material flow region length, faster transmission speed, maximally screen Applications Iron ore, limenite ore concentration plants Used to size control and concentrate grading. High frequency vibration fine screen screening efficiency, the product is enriched under the effect of screening significantly, thereby increasing the selection of selected grade (concentrate grade can be an increase of 1% to 3%). As the classification efficiency improves, the average particle size concentrate thickness, so that the concentrate filter conditions improve, with cake moisture decreased 0.5% to 1%.Tungsten Ore, Tin, Da Ore, Niobium Ore Concentration Plants Such ore are more brittle, heavy and thin screen can be used to replace high frequency vibration spiral classifier, cyclone classification, or with their combination of classification to significantly reduce between 8% to 15%, while the grinding system processing capacity of about 20 to 30%.Glass Raw Material Quartz Sand, Feldspar Concentration Plants Quartz rod mill product fractions are wide, angular and more difficult to screen. The use of high frequency vibration fine screen stables production of qualified products.Kaolin Concentration Plants Used to control the final product size or high gradient magnetic separator before every coarse. Techanical Parameters Vibration frequency 1,500 times/min. Separation concentration 0.074mm. Feeding Concentration : 25 � 50% (determined according to material property). Handling Capacity : 30 � 300 tones/hour (different separation amount leads to different separation size). Feeding Loops : 3,4,5. Screen Surface Incidence : 20 � 30* (determined according to separation size). Mesh Pore : determine mesh size according to separation size and material property. Noise : - 80dB. Ambient Temperature : not exceeds � 20-40 C. Feeding Ways : three-way, four-way, five-way. Vibration Motor : three-phase, 230V/4, 400V-50HZ, customized by U.S. Martin Company, imported . Electric vibrator exciting force 0-80,000N, adjustable. Lubrication Oil : special high-temperature oil High Frequency Ultra fine Vibrating Screen The fine screen uses two mutually independent screening system components, which is two traditional fine screen mounted on the same movable frame. Driven by a vibrator, each system consists of two pieces of screen mesh and equips with pulp tank lined with wear resistant polyester between the screen mesh with sprinklers, the products on screen can completely reversed and cracked into pieces in recycled pulp making tank to separate crude and fine material. Feeding Method The mandatory ore separating, a patent technology can spread pulp evenly on the screen to improve screening efficiency and processing capability. Secondary Recycled Pulp Making Technology The nozzle of the device compensates water directly to one or more recycled pulp making tanks, and the screening material is completely reversed and cracked into pieces in recycled pulp making tank. When the material moves downwards along screen surface, the most effective wet classification and the uttermost material separation can be gained by repeated pulp making and various screening. It is especially remarkable that compensating water directly to recycled pulp making tank can avoid the quick wear of screen mesh via compensating water directly to screen surface and the crude-escape phenomenon of material on screen via penetrating screen mesh forcible. High frequency ultra-fine vibrating screen with dust-proof structure The fine screen uses the principle of multi-stage screening, with long screening material flow region and much quicker transmission speed, and can remove the fine-grained level material from the feeding uttermost, greater screening capacity and effect can meet dry screen sub-job requirements, open or full closed anti-dust structure with maintenance side door can be used.

...more

Tubular Vibrating Feeder

Tubular Vibrating Feeder ensures safe transportation of material from the feed hopper to the required destination. Tubular Vibrating Feeder is available in round or square sections, suiting diverse demands of clients. Tubular Vibrating Feeder is manufactured in a range of sections from 100 mm to 500 mm and in lengths of up to 6.5 meters. Either Tubular Vibrating Feeder is powered by vibratory motors or electromagnetic drive units can be operated at tube angles from 14 uphill to 15 declination.

...more

Trommel Drive

We are offering trommel drive ( other product for gold). Trommel drive :(other product for gold) vibrating trommel screen are used to separate materials into various sizes for further processing, or for end use. Depending on particular need, the material is separated by passing it through a vibrating “screen box” which has a number of different sized screens or meshes, which the material falls through like a sieve, the material falls onto attached conveyors which stock pile the end products. The end products can then be used in the building and construction industries. features of vibrating trommel screen: high screening efficiency high capacity and reliability long bearing lifetime easy maintenance

...moreBe first to Rate

Rate ThisOpening Hours