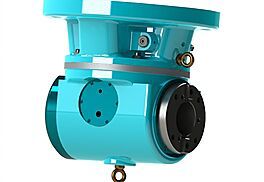

VWD FACING HEAD

VWD 500 / 630 – FACING HEAD The VWD 500 / 630 Facing Head is attached to the hollow spindle of horizontal boring machines. The Facing head is identical for all types of the machines with exception of the mount and the taper shank. Movement of the tool position is displayed by the digital read out, feed of the slide is selected from the panel of the machine. The Facing head performs operations such as Facing, Boring, Grooving, Contouring and Taper Boring etc., This Facing Head can perform as a NC Facing Slide when mounted on a CNC Horizontal Boring machine with independent movement of Ram & Spindle.

...more

VR FACING and BORING HEAD

VR 100 –FACING & BORING HEAD The VR 100 Boring and Facing head is applied for machining faces and cylindrical surfaces with different recesses, both from the front and from the rear of work piece. It is also suitable for the production of internal recesses and slots in holes. The Boring and Facing head is available with different taper shanks. The slide feeds are infinitely variable, derived from the rotary motion of spindle.

...more

IFW UNIVERSAL MILLING HEAD

1,690,000 - 1,700,000 Per Number

1 Set (MOQ)

VFW 1A – UNIVERSAL MILLING HEAD The VFW 1A Milling head is applied for light milling operations performed mainly in holes and on surfaces parallel with the main spindle centerline. No resetting of Work piece is required when using the mentioned Milling head. The VFW 1A Milling head is capable of being swivelled about two axes perpendicular to each other to scales provided. The swivel is effected manually by means of a worm gear through transmission 0-360°. After its adjustment the head is firmly fixed to its extension mount. Made in India since 1993

Finishing : Color Coated

Power : 55kw

Driven Type : Spindle

Automation Grade : Semi-automatic

...more

VFW UNIVERSAL MILLING HEAD

VFW 3A – UNIVERSAL MILLING HEAD The VFW 3A Milling head is applied for milling operations performed mainly in holes and on surfaces parallel with the main spindle centerline. No resetting of Work piece is required when using the mentioned Milling head. The VFW 3A Milling head is capable of being swivelled about two axes perpendicular to each other to scales provided. The swivel is effected manually by means of a worm gear through transmission 0-360°. After its adjustment the head is firmly fixed to its extension mount.

...more

VFW ANGULAR MILLING HEAD

VFW 3 – ANGULAR MILLING HEAD The VFW 3 Milling head finds its application mainly in milling operations performed in holes and on surfaces parallel with main spindle centerline. No resetting of Work piece is required when using the mentioned milling head. The VFW 3 Milling head is capable of being swivelled to various positions to a scale. The swivel is effected by hand by means of Worm Gear through 0-360° at required position.

...more

VFW ANGULAR MILLING HEAD

VFW 2 – ANGULAR MILLING HEAD The VFW 2A Milling head is applied for milling operations performed mainly in holes and on surfaces parallel with the main spindle centerline. No resetting of Work piece is required when using the mentioned Milling head. The VFW 2A Milling head is capable of being swivelled about two axes perpendicular to each other to scales provided. The swivel is effected manually by means of a worm gear through transmission 0-360°. After its adjustment the head is firmly fixed to its extension mount.

...more

VFW ANGULAR MILLING HEAD

VFW 1 – ANGULAR MILLING HEAD The VFW 1 Milling head is applied for light milling operations on small surfaces or for milling both external and internal slots which parallel with main spindle axis. It is also suitable for drilling small holes and, with special tools, for other operations such as production of internal clutch claws, internal splines and similar. The Milling head is capable of being swivelled by hand, to different angular positions through 0-360° to a scale provided. After adjusting the required angular position the Milling head is firmly fixed to its extension mount.

...more

VFH ANGLAR MILLING HEAD

VFH 3 – ANGLAR MILLING HEAD The VFH 3 duplex Milling head is applied for milling several faces which are parallel with the main spindle axis. The spindle of this head is fitted with taper at either end for clamping the cutters. The head may be swivelled through 0-360° by an worm and worm gear arrangement at required position. The VFH 3 duplex Milling head is designed for efficient Milling. It will prove advantageous in angular Milling of several faces which are parallel with the main spindle axis.

...more

TWO AXIS FORK TYPE MILLING HEAD

TWO AXIS FORK TYPE MILLING HEAD These Fork type milling head can be mounted on Rams of Vertical Lathes, Portal machining centers or on Ram type Horizontal boring machines.The heads are offered in two versions (i.e) Heavy duty spindle driven by the Ram spindle motor itself with max RPM of 2000 High speed motorized spindle delivering 15 – 20000 RPM.

...more

Travelling Column Horizontal Drilling MACHINE

This machine is designed as a floor type horizontal milling, drilling and boring machine. A column moves on a bed fitted with linear motion guide ways and on the faces of the column a Ram head moves vertically constituting X and Y axis. As the machines are built modular various X, Y, Z combinations can be offered to suit specific requirement of the customer. This machine can be offered with various accessories like right angle milling head, facing and boring head, universal milling head etc..

...more

TOS Horizontal Boring Machine

7,500,000 - 15,000,000 Per INR

1 Piece (MOQ)

Machine Travel Specifications X axis 3500mm Y axis 2500mm Z axis 1250mm W axis 800mm Table Specifications Size 1800mm X 2200mm Weight 12000kg / 26500lb max Table Travel Specifications B axis 360 V axis N/A

Type : HBM

Certification : Iso

Weight : 80000

Color : GREEN

Voltage : 220V

Condition : Used

Automatic Grade : Automatic

Power : 37

Driven Type : Electric

Country of Origin : CZECH REPUBLIC

Brand Name : TOS

...more

Skoda FV Plano Milling Machine

Skoda FV 1000 Plano Milling Machine Retrofitted with 3 axes Siemens CNC Control. Machine Table Size 3100 X 1100 retrofitted with 3 axis contouring capability.

...more

Cnc Vertical Lathe Machine

This machine is designed as 2 axis or 4 axis CNC VTL with fixed cross rail and two rams simultaneously turning the component for higher productivity. The CNC vertical lathe machine, CNC vertical turret lathe machine can be fitted with ATC on one ram or two rams. All the features of the vertical lathe machine and vertical turret lathe machine are designed keeping in mind higher productivity and are offered with various accessories like 4 Jaw Chuck, 3 Jaw Hydraulic Chuck, Chip Conveyor etc. The CNC vertical turret lathe machine can also be tooled up for your component. The CNC vertical lathe machine can be supplied with single ram as well CNC system offered are siemens/Fanuc. The sizes offered are 800 mm,1100 mm and 1400 mm Swing/Turning dia. Turn mill options also available. Get Catalogue

...more

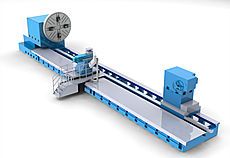

roll turning lathe

Customer: TYCO ROLLS LTD-JAMSHEDPUR 1600 Dia X 8 Mtr Roll Turning Capacity Retrofitted with Two Axis Siemens CNC Controller.

Country of Origin : India

Type : Horizontal Lathe

Brand Name : VHS MECHATRONICS SERVICES PVT LTD

Certification : CE Certified

Material : Cast Iron

LED Indicator : Yes

Phase : Three Phase

Condition : New

Warranty : 1 Year

Corrosion Resistance : Yes

Automation Grade : Automatic

...more

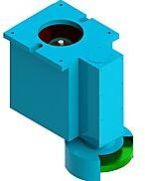

RIGHT ANGLE MILLING HEAD

RIGHT ANGLE MILLING HEAD The Right Angle Milling head finds its application mainly in milling operations performed in holes and on surfaces parallel with main spindle centerline. And can be mounted on the Ram of Vertical Lathe and Horizontal Boring machine and Portal machining centre.

...more

PLANING MACHINE CONVERTED TO PLANO MILLER

Planing Machine Converted to Plano Miller with Two RAM type, Universal Milling Head, Ball Screws and Servomotors PLC Controlled. Customer: BHEL Trichy, Machine Specification: Table: 2500 X 12000 Table Power: 80 KW. Milling Head Power: 37 KW each

...more

HEAVY DUTY CNC ROTARY TABLE

HEAVY DUTY CNC ROTARY TABLE The Rotary table models VRT series are designed for integrating with any CNC horizontal boring machine fitted with Siemens 840D controller having additional axis capacity or with an independent controller Siemens 802 D .The rotary table position can be continuously controlled in two axis one rotary ‘B’ axis and the another longitudinal ‘V’ axis. The rotary table bed made of grey cast iron grade 30 heavily ribbed. The Rotary table movement is through a Double Pinion Gear Box driven by one or two Servo motors as required. The table and saddle guide ways are hydrostatic and can be hydraulically locked after indexing.

...more

Heavy Duty CNC Roll Turning Lathe

The company has reached the pinnacle of success in offering CNC horizontal boring machines. Our offered product is known for the strength, excellent quality, reliability, low maintenance cost and ease of operation. The product is use in variegated industries, and is used to conduct efficient boring operations. Driven by a desire to attain maximum customer satisfaction, we have been able to deliver the products within the stipulated time frame.

...more

motorized grinding attachments

These motorized grinding attachments are offered for mounting on the Ram of Vertical lathes and also an Horizontal boring machines.

...more

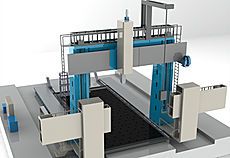

Gantry Machining Centre

These machines are designed for Milling, Drilling, Thread Milling and Contouring on large size components. Two Columns connected by a top beam, moves on two amply dimensioned bed ways, driven by two Servomotors in Master Slave mode. The movement is through hardened and profile ground helical rack and Double Pinion Gear Box with hydraulically eliminated Back lash. The guide ways of the Column saddles are hydrostatic.

...more

FACING and BORING HEAD

IV 25-FACING & BORING HEAD The IV 25 Boring head is applied in machining faces and cylindrical surfaces with different recesses, both from the front and from the rear of Work piece. It is also suitable for the production of internal recesses and slots in holes. The Boring head consist of the head body which serves as a guide for the traversing slide. The slide is fitted with several holes to receive different tool holders. The body is fitted with a cylindrical shank. The rotary motion of the spindle is transmitted by means of gears and a worm to a nut which is moving the slide. The feed motion is infinitely variable.

...more

DOUBLE COLUMN VERTICAL TURNING MACHINE

DOUBLE COLUMN VERTICAL TURNING AND BORING MACHINE MODEL SK 40 - 400MM TURNING DIA. Customer: M/s. Bay Forge Ltd-Chennai. Retrofitted with Siemens 4 Axis CNC Controller with Thread Cutting and Constant Surface Speed control.

...more

Double Column MCNC machine

This double column CNC machine or vertical double column CNC machine is designed as moving cross rail double column vtl with two ram slides moving across the cross rails and the rams moving vertically are controlled by servo motors through ball screws by CNC Controller. The table is located at the centre by two heavy duty spherical roller thrust bearings and at the periphery by a hydrostatic flat guide which is lined with “Biplast” material for smooth operation on load. The loading capacity of the table is designed for job weight upto 40 tons. A two speed gear box with automatic shifting of gears provides adequate torque / power at different speed of table. An encoder fitted with “one to one” ratio with table allows thread cutting and constant cutting speed facility with one of the ram slides.

...more

Double Column Fixed Cross Rail CNC VTL

Tell people more about this item. What's it about and what makes it interesting? Give people the info These machines are designed as 2 & 4 axis CNC VTL's with two rams simultaneously turning the components for high productivity. The double column vertical lathe machine and double column vertical turret lathe machine are offered with heavy duty 4 jaw face plate chuck as standard. Any other clamping device like hydraulic chuck or fixture or EPM chuck can be mounted on the 4 jaw face plate. These double column vertical lathe and double column vertical turret lathe can be offered with build in spindles on the ram and C - axis indexing of the table for PCD drilling/tapping etc. These machines can be offered from 1800 mm. dia. swing onwards to 5000 mm swing and for height of job upto 1500 mm.

...moreBe first to Rate

Rate ThisOpening Hours