Vibrating Screen

80,000 Per Piece

1 Piece(s) (MOQ)

Circular Gyro Vibrator Screen

110,000 Per Piece

2 Piece (MOQ)

Best Deals from Vibrating Screen

Horizontal Incline Screen

Get Price Quote

1 Piece (MOQ)

Horizontal Vibrating Screen

180,000 - 600,000 Per Number

1 Piece (MOQ)

Horizontal Type Vibrating Screen

Get Price Quote

We are offering horizontal screen. vibrating screens are used for vibratory motors to drive the mechanism. It has several advantages like simplicity, compactness, and reduced maintenance and less installation cost. By mounting the entire drive mechanism on screen, many accessories are made by external drive motor, motor support, v belts and shaft drive components. It is designed for wet and dry operation. These machines offer outstanding services in product sizing, regretting, medium recovery, and trash removal. Screen sizes range from 300 x 900 mm to 3000 x 9000 mm in single, double and triple deck configurations. The deck materials include wire mesh, polyurethane and perforated plate. Accessories such as dust enclosures, integral spray pipes, sub frames, outlet chutes are also provided. Rectangular screen separator made by us goes according to the pattern specification and requirement. Features: » versatile all round applications. These are efficient for screening of wet and dry sand, gravel, crushed stone, plastics, ores and minerals. » simple efficient vibrating motor offer drive mechanism » rugged construction. » compactness: less area required for installation and no external drives inclined screen: we manufacture a wide range of inclined screen that fulfills the specific requirement. These machines are powered by paired vibrating motors or three motors and tested externally by driven single oscillator mechanism. These screens can be made for variant configurations, number of decks and screen sizes.

Vibrating Screen

Get Price Quote

The offered range is manufactured using premium quality materials that are highly durable, resistant to adverse conditions and have superior tensile strength. Accessible at the most economical rates, we guarantee only quality tested products to be delivered to our customers.As one of the leading manufacturers, exporters and suppliers, we have the privilege to offer our clients an elaborate range of Vibrating Screens that is fabricated using optimum grade spring steel, galvanized steel, mild steel and stainless steel. The offered range finds wide application in the ceramics industry, automobiles industry, biscuit industry, cement industry, food industry, lime minerals industry and clay industry. Furthermore, these screens are available for our respected clients at highly cost-effective prices.

Circular Vibrating Screen

75,000 Per Piece

10 Piece (MOQ)

Vibratory Screens

Get Price Quote

We are the leading manufacturers and exporters of Vibrating Screens. Our vibrating screens have a wide range of applications such as coal dressing, power station and water conservancy project. These vibrating screens are used in many industries like metallurgy, mine, building, light and chemical industry. Features Durable High screening capacity Screen plates can change easily No transmission of screen panels

Dewatering Vibrating Screen

Get Price Quote

we bring forth cutting-edge dewatering vibrating screen that is tremendously advantageous for reduced maintenance, compactness and simple operations. Apart from the simplicity of the drive, a lot of other features have been incorporated in this dewatering vibrating screen for heavy duty applications, long life, and low operating and maintenance costs. This dewatering vibrating screen comes at a competitive price. advantages the use of the following equipment becomes unnecessary: external drive, with vee-belts or cardan shaftsoil bath oscillators, with synchronizing gears and oil leakssnubbers - the screen-mounted drive has eliminated the need for snubbers to reduce damage to vee-belts and external motors during the large oscillations that normally occur during stoppingbearing failure is limited to the bearing itself. Particles from a failed bearing cannot circulate in motor support stand, or overhead structure for motor supportan oil bath and cause possible damage to other bearings and synchronizing gearscompactness - screens can be positioned very closely with a minimum of space wastagedue to the absence of gears and vee-belts, the units use less power than conventional drivesa vibrator motor needing reconditioning can easily be exchanged for a standby unit, with a minimum of downtime.

Vibrating Screen

Get Price Quote

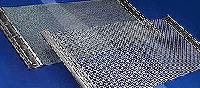

Vibrating Screen - Coarse type of wire mesh are normally used for making screen for vibrating machines. Salient Features ✔ Screens are woven accurately to the mesh size with appropriate wire or rod to meet specific requirements. ✔ Screens are offered in spring steel, mild steel, galvanized steel and stainless steel to suit particular applications. ✔ In vibratory finishing, energy in the form of vibratory forces is transformed by the machine's drive system into a mass of loose media and then into the parts. ✔ The entire load is in motion at the same time so that the media act against the parts throughout the complete mass. ✔ Basic elements of the system include the machine, the media, and the compound and/or water solution. Selection of each depends primarily on the parts being run - that is, the type of parts: size, shape, and condition; and the work to be accomplished.

Vibrating Screen

Get Price Quote

Supplier, Trader, Whole seller and Stockist of vibrating screens such as industrial Vibrating Screen, strong vibration screens, lesser noise vibrating screens, safe vibrating screens and construction vibrating screens.These Vibrating Screens are widely demanded in several small scales to large scale production industries and are widely used for crushing or grinding various kind of industrial raw material.Applications: Sand & gravel Crushing stone Minerals Pellets Granule material Salt & sugar Ceramics

Vibro Screens

Get Price Quote

Star Trace actively catering to the needs of various industries as the single source, for custom Built Material Handling systems and equipments, have added over the years to the manufacturing program, a wide range of size reduction and separation equipments. Star Trace updated know-how, product development, research and awareness is making crushing and screeing jobs more efficient. In addition to the various types of crusher and vibrating screens, Star Trace takesup turnkey jobs of complete crushing and screenng plants, right from concept to commissioning, capable to handle all kinds of rocks, ores, mineral and lumpy hard materials, even, quarries and other industries. VIBRATING SCREENS : Star Trace Vibrating Screens has wider range of applications. It is a two bearing free floating vibrating screen which efficiently screens all moderately free flowing materials. The circular throw action is dervied from unbalance weights which are suspended from the vibrator unit and transmit an uniform vibration to screening surface and ensures that material travels over the screening surface at a constant rate. The amplitude of degree of vibration can be adjusted to suit charge of duty by adding or removing unbalance weight plates. Circulars motion ensures rapid stratification at the feed end separates sized product in the shortest possible time. Screen's inclination normally varies between 15 Deg. and 20 Deg. and can can be installed with fixed angle or adjustable bracked arrangement. Speed of screen varies between 800 R.P.M and 1200 R.P.M Screens are manufactured in following widths 600, 800, 1000.1200, 1400, 1600, 1800, 2000 m.m and and lengths varying from 1200 mm to 600 mm Number of decks can be upto four.

Vibrating Screen

Get Price Quote

These are manufactured using superior quality MS plates obtained from reputed companies like ESSAR and SAIL. Our broad gamut is created in compliance with IS – 2405 part – II standards and known as embossed plate, screen as well as crusher screens. We develop the offered Vibrating Screens & Plates on automated power presses to ensure durability and precise dimensions. Specifications:❖ Range of production: 0.3mm to 90mm ❖ Dia Hole Sheet Thickness: 0.19mm to 12mm Product Specification Aiming on excellent quality, we are able to offer optimum grade Vibrating Screen Cloth. Cutting-edge technology and latest machines are used by our skilled professionals to manufacture these products. These products are mostly use in mining, chemical, coal and construction industries for their excellent performance and long lasting service. Keeping in mind the various needs of our customers, we offer the Vibrating Screen Cloth in many specifications. Our company is known as a genuine supplier, manufacturer of Vibrating Screen Cloth. The cloth ie created from graded spring steel, carbon steel, stainless steel and many other well inspected components. This Vibrating Screen Cloth is carefully placed over rubber beads to avert contact between metals. Our material is widely used in power plants and cement, paper, coal, mining, cement as well as many other industries. Moreover, we can custom design this cloth according to the demand. Product Range : Vibrating Screen cloth is available in sizes from 0.5mm to 100mm with wire diameter from 0.2mm to 16mm. Area Of Application : The vibrating screen cloth got an extensive use in many industries such as : power plants, coal, chemical, mining, paper and pulp, quarrying, iron ore and steel, cement and stone crushing, etc. End Use : Vibrating screen cloths are used for doing works like sizing, screening, shifting, grading, separating, scalping and washing.

Horizontal Vibrating Screen

Get Price Quote

''EFI'' Horizontal screen design is proven in hundreds of mining, ore and mineral applications. Custom-engineered designs may include side tensioned wire mesh screen decks. Multiple sizing decks (on a single unit), explosion-proof motors and Variable Frequency drives are important high-performance options. The wide variety of screening decks gives you improved performance for processing that follows size reduction mills or crushers.

Vibro Screen

Get Price Quote

We has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The screens works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power. The screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These screens can handle wide range of materials such as heavy, light, dry, wet, coarse or fine.

Vibrating Screen

Get Price Quote

Vibrating Screen is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. For material quality of screen mesh is changeable, the application is quite extensive.

Vibrating Screen

Get Price Quote

We are manufacturing Vibrating Screens in different models having single, double and triple decks, depending on the requirement of customers.Vibrating screens are used in Sieving, Sorting, Grading, Sizing, Extracting, Conveying, Segregating, Granulating, Dewatering and other Separating and Filtrating Solutions. Heavy Duty Wire Mesh Screens are specially manufactured for extremely rugged operating conditions in scalping, sizing or processing heavy abrasive materials such as ores, crushed stones, sand, gravel, metallic and non metallic minerals, coal slag etc.The strength and free screening area advantages of woven wire screens over other screening media make them suitable for many industrial sifting and separating applications. As well as supplying to the mine and quarry Industry, the screens are used in many other areas including precious metals, ore grading, water treatment, coal preparation, foundries, waste management, agriculture and food processing. Vibration Screens are made out of Spring Steel, Galvanized Iron and Stainless Steel, as per the specifications given. Vibration Screens can also be custom made from Coarse to Fine Apertures made out of Abrasion-Resistant Spring Steel, Stainless Steel, High Carbon High Tensile, GI, Mild Steel Wire etc. with or without Edge-

Industrial Vibrating Screen

350,000 - 400,000 Per Piece

Vibratory Screen

Get Price Quote

Vibrating Screening Machines are intended for screening of powders. These machines are basic and strong in development. The Vibrating screens are likewise accessible with attractive framework to uproot Fine iron. Sullying from items like Chemicals, Pharmaceutical and Nourishment items and so forth. We are one of the pioneer producer and exporter of Vibro Screen and Gyro Screen in India by prospering on proficient initiative, designing predominance, brilliance, and bleeding edge innovation.

Rotary Screener

150,000 Per unit

Polyurethane vibrating shale shaker screen

Get Price Quote

Rotating Drum Screen

600,000 Per Piece

Inclined screens

Get Price Quote

Inclined screens, Magnetic Equipments, electro mechanical feeders

gyratory screen separator

Get Price Quote

gyratory screen separator, Permanent Magnetic Separator, Separation Equipment

Vibrating Screen

Get Price Quote

dense phase conveying systems, apron conveyors, weigh feeder controller

Dewatering Vibrating Screen

Get Price Quote

VIBRATING SCREEN BOLTS, Vibrating Screen Cloth, PU Mesh, HYDROCYCLONE PU

Perforated Screen Plate

Get Price Quote

Perforated Screen Plate, Auto Guide, Hydro Pulper

Rotary Screen

Get Price Quote

Rotary Screen, cane mud filters, Industrial Process Equipment

Linear Motion Vibrating Screens

Get Price Quote

Electromagnetic Overband Magnetic Separator, Magnetic Grill Drawer

Vibrating Screen

Get Price Quote

Perforated Sheet, Silencer, sintered filter, moisture seperator