Ozone Water Treatment Plants

Get Price Quote

Ozone water filtration is an extremely solid, expansive range disinfectant that is broadly utilized as a part of around the world.

Water Purifier

Get Price Quote

Best Deals from Water Treatment Plant

Water Softener Plant

Get Price Quote

Owing to our capacity of meeting the exact requirements of the clients, we are supplying quality Water Softener Plant. We are a quality centric organization, offering the best-in-class products that are manufactured using the experts approved and certified raw material procured from reliable sources.Softener Plant for Cooling Tower Application and Other Indstries like Dairy Units

Industrial Ro Plant

Get Price Quote

We are a wide range of industrial reverse osmosis plants which comes at a flow rate from 200LPH. Our industry professionals utilize the company resource for incorporating efficient water treatment mechanism for commercial buildings and industries. the range is designed as per the set industrial norms and clients. Excellent functioning Fully automatic operation long operational life less maintanence Durable body structure

Dolphin Gold Plus RO Water Purifier

6,999 Per Piece

1 Piece(s) (MOQ)

dolphin gold plus ro water purifier chennai.

Sewage Treatment Plant

Get Price Quote

Sewage is generated by residential, institutional, commercial and industrial establishments. It includes household waste liquid from toilets, baths, showers, kitchens, sinks and so forth that is disposed of via sewers. In many areas, sewage also includes liquid waste from industry and commerce. The separation and draining of household waste intogreywater and backwater is becoming more common in the developed world, with greywater being permitted to be used for watering plants or recycled for flushing toilets. Sewage may include storm water runoff. Sewerage systems capable of handling storm water are known as combined sewer systems. This design was common when urban sewerage systems were first developed, in the late 19th and early 20th centuries.[2]:119 combined sewers require much larger and more expensive treatment facilities than sanitary. Heavy volumes of storm runoff may overwhelm the sewage treatment system, causing a spill or overflow. Sanitary sewers are typically much smaller than combined sewers, and they are not designed to transport storm water. Backups of raw sewage can occur if excessive infiltration/inflow (dilution by storm water and/or groundwater) is allowed into a sanitary sewer system. Communities that have urbanized in the mid-20th century or later generally have built separate systems for sewage (sanitary sewers) and storm water, because precipitation causes widely varying flows, reducing sewage treatment plant efficiency. As rainfall travels over roofs and the ground, it may pick up various contaminants including soil particles and other sediment, heavy metals, organic compounds, animal waste, and oil and grease. (See urban runoff.)[4] Some jurisdictions require storm water to receive some level of treatment before being discharged directly into waterways. Examples of treatment processes used for storm water include retention basins, wetlands, buried vaults with various kinds of media filters, and vortex separators (to remove coarse solids).

Disc Diffuser

Get Price Quote

We make available to the clients exceptional quality Fine Bubble Disc Diffuser, which is manufactured using highly advanced technology. The Fine Bubble Disc Diffuser offered by us is precisely engineered to suit the specifications of various clients. Additionally, clients can avail this Fine Bubble Disc Diffuser at most discounted prices. Features High shelf and service lifeVery fine bubble aerationEfficient oxygen transfer rateNon-cloggingLow maintenanceGood Mechanical strengthHigh temperature resistance Applications In a fixed Aeration system where the pipes are bolted to the floor, and longevity and low maintenance are required, disc diffusers are highly efficient.Textile EffluentPaper, Sugar EffluentAquaculture AerationSwimming PoolsSpecification Download

Wastewater Treatment Plant

Get Price Quote

We also provide an integrated system of anaerobic and aerobic process for treatment of waste water from various types of industries. In the Anaerobic Digester tanks populations of anaerobic bacteria typically take a significant period of time to establish themselves to be fully effective. It is therefore common practice to introduce anaerobic microorganisms from materials with existing populations. This process is called 'seeding' the digesters and typically takes place with the addition of sewage sludge or cattle slurry. Cattle slurry is filled in the anaerobic digester tanks. We use PVC pipe with close holes for uniform flow of raw water in the slurry. There is a typical baffle which settles the solid particles in the slurry from rising up. The purpose of horizontal launder is to collect the water overflowing from the tank to the next stage of aerobic process. The biogas produced by this process is collected in a duct and used for several application. This treatment plant employs coupled biological process with specific Bacterial Cultures and required Chemicals for decolorizing waste water and the output satisfies all parameters of Pollution Control Board.

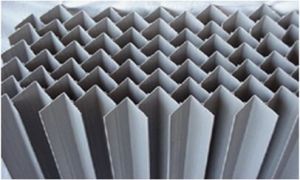

Tube Settler Lamella

7,900 Per Cubic Meter

1 Cubic Meter (MOQ)

Tube Settler

Get Price Quote

Description Leveraging on the expertise of our skilled professionals, we have been able to manufacture a comprehensive assortment of Tube Settler Media. Enhancing the settling capacity of water clarifiers, the tube settlers make use of isolated tubular channels. Our experts make use of flame resistant raw material, which is procured from the certified vendors of the market. Available at cost-effective prices, the entire range can be custom-designed in accordance with the specific requirements of the clients. Clarification/Sedimentation is the most important stage in the field of waste water treatment. The most efficient sedimentation systems have high settling surface area whilst maintaining a small structure. PROFLEX Tube Settler media provides a large settling surface area within the specified volume thus giving high flow rates. They have a chevron shaped self-supporting structure in a tubular form with six sides. They are primarily used in applications like water treatment, primary & secondary clarifiers in wastewater treatment. We are one of the distinguished manufacturers and exporters of a wide range of Tube Settler Media, which are ideally designed to augment the performance of new and old bio reactors. These products have received wide acceptance in the national and international market for its high usability, durability, cost effectiveness and wide variety. Some other salient features of these products are: Features High shelf and service lifeVery fine bubble aerationEfficient oxygen transfer rateNon-cloggingLow maintenanceGood Mechanical strengthHigh temperature resistance Applications Industrial Effluent TreatmentMunicipal Effluent TreatmentDiffused Aeration TanksSpecification Download

Sewage Treatment Plant

950,000 - 1,000,000 Per Piece

Hot Water Generator

400,000 Per Piece

Membrane Bioreactors

Get Price Quote

Two versions of the MBR process are offered by KANKYO, the KANKYO Submem and the KANKYO Crossmem. The KANKYO Crossmem is based on a cross-flow filtration process. The biomass is filtered in a filtration unit besides the bioreactor. The KANKYO Submem is based on filtration with submerged membranes that are submerged in the Membrane bioreactors for wastewater treatment is a combination of a suspended growth biological treatment method, usually activated sludge, with membrane filtration equipment, typically low-pressure microfiltration (MF) or ultrafiltration (UF) membranes. The membranes are used to perform the critical solid-liquid separation function. In activated sludge facilities, this is traditionally accomplished using secondary and tertiary clarifiers along with tertiary filtration. The two general types of MBR systems are vacuum (or gravity-driven) and pressure-driven systems. Vacuum or gravity systems are immersed and normally employ hollow fiber or flat sheet membranes installed in either the bioreactors or a subsequent membrane tank. Pressure driven systems are in-pipe cartridge systems located externally to the bioreactor An “MBR System” is considered to be a complete and integrated membrane unit (sub-systems) with related components necessary to allow the process to function as desired. An MBR, or Membrane Zone, can best be described as the initial step in a biological process where microbes are used to degrade pollutants that are then filtered by a series of submerged membranes (or membrane elements). The individual membranes are housed in units known as modules, cassettes, or racks and a combined series of these modules are referred to as a working membrane unit. Air is introduced through integral diffusers to continually scour membrane surfaces during filtration, facilitate mixing and in some cases, to contribute oxygen to the biological process. Advantages Very stable process The conventional biological system is sensitive to the wastewater composition. Due to variations in wastewater composition and/or presence of complex or toxic substances, high salt concentrations or low oxygen concentrations, the biomass floc formation is poor and the settling process will not perform well. This results in discharge of the micro-organisms and poor effluent quality. The membranes will however withhold all biomass and other suspended solids, ensuring a high effluent quality. Very compact design Due to the membrane separation the active micro-organism population in the bioreactor can be maintained at a concentration 4-5 times higher than in conventional systems. This results in bioreactor tank volumes of only 20-25% of the size of conventional systems. A clarifier, being a space-consuming tank, is not required. High effluent quality The ultra filtration membranes withhold all micro-organisms and most suspended solids, resulting in a clear and highly purified effluent. The effluent may be reused as low-grade process water or for irrigation purposes. Low sludge production The MBR can operate at a low F/M ratio, being the Feed of organic substance per amount of Micro-organisms per time unit. This results in a high mineralisation of sludge. In conventional systems 1 kg COD will result in about 0,3 -0,4 kg of biomass. With MBR systems 1 kg COD is converted to 0 - 0,2 kg biomass (zero biomass production can be obtained when operating at high temperatures). The discharge of biomass can have significant impact on the operational costs of the system. Treatment wastewater up to 60 °C is possible Treatment of wastewater with chlorine concentrations up to 120 g/l Insentive to shock and vibration (on board of ships) Field of Application: Poorly degradable water (lightly sludge-sensitive) In limited space Stringent discharge regulations Reuse

waste water recycling plant

Get Price Quote

Waste Water Recycling Plant With rich industry experience, we are trading and supplying a wide assortment of Waste Water Recycling Plant. Designed with utmost precision under the guidance of vendor’s experienced engineers, our offered plant is environment friendly and is the best way to produce fresh water for industries, agriculture, etc. Owing to the salient features such as easy installation, low maintenance, proper functioning, high efficiency and longer service life, this has gained huge demand in the market. Clients can avail this plant from us at industry leading prices.

Industrial Water Pump

25,000 Per Units

1 Units (MOQ)

Dolphin RO Water Purifier

Get Price Quote

Dolphin RO Water Purifier, aqua grand plus ro water purifier

Water Treatment Plants

Get Price Quote

Water Treatment Plants, Adhesives, latex adhesives

Water Treatment Plants

Get Price Quote

Water Treatment Plants, Activated Carbon Filter, Alum Powder

Hot Water Generators

Get Price Quote

Hot Water Generators, Steam Boilers, Thermic Fluid Heaters

Aquaculture Aerators

Get Price Quote

Aquaculture Aerators

Sewage Treatment Plant

Get Price Quote

Sewage Treatment Plant, Effluent Treatment Plants, Water Treatment Plant

Reverse Osmosis System

Get Price Quote

We are offering reverse osmosis system. we have emerged as foremost trader and supplier of superior quality reverse osmosis systems, which are sourced from the reliable vendors of the market. The key function of these systems is to remove salt contamination from brackish water sources and is improved water purity. Apart from this, our offered systems require less power and minimal co2 emission. Further, we provide these systems in various specifications in order to meet varied applications in hospitals, laboratories, industries, houses, etc.

Sewage Treatment Equipment

Get Price Quote

Sewage Treatment Equipment, Membrane Water Treatment, Sewage submersible pump

domestic ro

Get Price Quote

domestic ro, Resin, distribution systems

Water Purifier

Get Price Quote

Water Purifier, commercial water purifier machine, water filling machines

Water Purifier

Get Price Quote

Water Purifier, RO System, Water Softeners

Water Purifier

Get Price Quote

Water Purifier

Water Treatment Plant For Waste Water

Get Price Quote

Water Treatment Plant For Waste Water, Water Treatment Plant

Water Treatment Plants

Get Price Quote

Water Treatment Plants, Solar Off Grid power systems, Solar Street Lights

Containerized RO water Plant

Get Price Quote

Containerized RO water Plant, SS Water Coolers, Mineral Water Bottling Plant