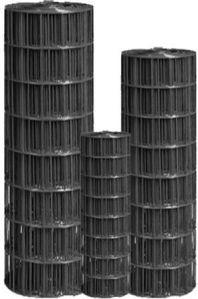

Welded Wire Mesh

Get Price Quote

In recent times the value for this product has become phenomenal. Manufactured in M.S., G.I stainless steel, PVC (304,316, 316 L, 310 and all other grades). Made from 1 feet to 3.2 meter width with a wire range of 0.5 mm to 25 mm wire dia. Wide variety of mesh opening offered is from 6 mm to 12 inches in opening. Few application of this are Cooling Tower, Concrete pipe (water line), Re-enforcement Road laying, Industrial roof insulation (G.l.3"x 16 G), Poultry cage, Mosquito repellent industries, Tree guards, Modern kitchen rack system, Partition and many more application, shapes like square and rectangular (vertically & horizontally) are available.

Welded Mesh

14 Per Square Feet

Best Deals from Welded Wire Mesh

Welded Mesh

Get Price Quote

The presented range is available in various sizes and shapes in accordance with the clients' requirements. Further, it is widely used in agricultural, industrial, transportation, horticultural and food procuring sectors. It also finds application in mines, gardening, machine protection and other decorations.With our specialization in manufacturing, exporting and supplying a range of fencing, we offer Welded Mesh which is developed using optimum quality substance. These are specially designed for commercial nurseries, greenhouses, horticulture and floriculture. The offered products are tested under different parameters to assure their durability and robustness. In addition, these are absolutely biodegradable & eco-friendly, and can be availed at industry leading prices.

Welded Wire Mesh

Get Price Quote

WELDED WIRE-MESH

Get Price Quote

Welded Wire Mesh (WWM), a relatively new product in India. Welded Wire Mesh is used as steel reinforcement in concrete, replacing the traditional “cut & bend” and placing of steel TMT bars. Welded Wire Mesh is used as steel reinforcement in concrete, replacing the traditional “cut & bend” and placing of steel TMT bars. We supply high quality WWM with precise dimensional control. The product will result considerable savings in time, labour and money. It is an Electric fusion welded prefabricated reinforcement consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. This concept is a step forward in the mechanization of reinforcement laying. It is the easiest and correct solution for achieving the requirements of quality, reliability, speed and efficiency at construction site.Advantages of Using Welded Wire Fabrics Because bars are welded in a mat, the bars do not move when concrete is placed, insuring bars are in their proper position. Since WWR is prefabricated and welded in plants, the risk of missing a bar is minimized. The chance of improper bending of bars is reduced by using WWR since bending machines bend the mat as a single unit The use of WWR minimized the chance of misplacement since only one type of mat is used on a given section. Provide the exact size of reinforcement where needed through variable bar size and spacing, thereby reduces steel waste. No site space needed for steel assembly. Faster erection time means you can beat changing weather conditions. Removes reinforcement placement from the critical path. Less field labour needed. The material fabrication is automated. With faster construction, insurance premiums are reduced. For example on bridge deck construction the barrier walls can be constructed faster reducing the time for fall exposure and reducing insurance premium. WWR can reduce construction time, thereby saving: Crane rental time Equipment leasing Increasing bonus Lower material cost because not fabricating small bar. Concrete ReinforcementStructural Slabs & WallsWWF instead of Individual Bars makes the job of reinforcing slabs/walls for residential, office and Institutional Buildings most quick and elegant. With detailing advantages, it also results in savings of 15 to 35% Roads / PavementsLarge area Floor labs on ground, pavements, airports, runways, aprons etc to achieve crack-free joints less surfaces.Precast MembersPrecast elements which are thin or are difficult to reinforce such as curved arch flat members, Hyperbolic Paraboloid Shells, folded plate roof girders, fins, thin pardis or chajja drops.

Mild Steel Weld Mesh

Get Price Quote

We are the leading exporters and supplier of this products.

Roll GI Welded Wire Mesh

Get Price Quote

Pvc Coated Welded Wire Mesh

750 Per Roll

Weld Mesh

Get Price Quote

Weld Mesh, Perforated Sheet, Expanded metals, Chain Link Fencing

Weld Mesh

Get Price Quote

Weld Mesh, Metal Component, metal sheet, Wire Netting, fencing

Welded Mesh

Get Price Quote

Welded Mesh, mesh products, Mosquito Mesh, Expanded Metal Mesh