Air Cooled Condensers

Get Price Quote

MODEL: ATE10-CON/ACIT REMOVES HEAT BY BLOWING AIR TO THE CONDENSER COIL. CHARACTERISTICS OF AIR COOLED CONDENSERS COMPACT,EASY AND ECONOMICAL TO INSTALL FLEXIBILITY IN CHANGING CAPACITY BY VARYING AIR FLOW HOT AIR MAY BE DISPOSED OFF EASILY EASY TO CLEAN FIN AND TUBE BY BLOWING AIR REQUIRES LESS MAINTENANCE HIGHER POWER REQUIREMENT PER TON OF REFRIGERATION

Sensors

Get Price Quote

For measurement and control in any industrial equipment, machines, automobiles, many data are required. Sensors are the key components which detects speed, position and temperature etc., and helps to take the necessary control actions. We offer sensors for measuring Speed, Temperature, Position and Pressure. We also offer customised sensors. Applications Speed : ABS in automobiles, engine speed, vehicle speed control, Turbine speed, forklift speed and direction, Locomotive Traction motor speed sensing. Applications Temperature : Engine oil temperature, Radiator coolant temperature, Air inlet temperature sensing. Over current protection Applications Position : Flap angle rotation, linear distance, arm position angle Applicati ons Pressure : Brake fluid, High pressure cleaner, Hydraulic systems and HVAC 01 Speed sensors : Contact and non-contact types, Single or dual output with either Voltage or Current output, Speed range 0 to 5000 rpm, output signal: sinewave or square wave. 02 Temperature sensors : NTC or PTC from -40 to 200°C, different threads and connector options. Pt 100 up to 500°C 03 Position sensors : Contact type, Resistive output, Standard angles of 90° / 180° / 360° Linear and rotary, long life, standard / custom rotary angles 04 Pressure sensors : Thick film technology, 0 to 500 bar, absolute/Relative Various thread sizes / connector options

Best Deals from Air Conditioning System

Three Phase AC Motors

Get Price Quote

Details : Well Suited for Industrial use. Work under low voltage Condition with high efficiency ISI & ISO certified company products. Easy to install and service Graded cast iron parts for longer duration. Aluminum die cast rotor only used Technical Specifications : High torque. High efficiency 180-220 voltage for Single phase 300 to 440 voltage for three phase operation. Application : All types of Industrial motors Bore well compressor motor, Air compressor,pulvarisor motor Special features : Using S.S 410 shaft , Double side sealed roller bearing Aluminum die cast rotor CRNO graded Stampings , Centrifugal switches are used

Double Skin Floor Mounted Air Handling Unit

110,000 - 230,000 Per UNIT

1 UNIT (MOQ)

Mild Steel Condenser

Get Price Quote

Exhaust Fans

Get Price Quote

Exhaust fans deliver the industry’s best performance and durability for grease contaminated air and general clean air applications as found in food service and fume hood exhaust. We offer the most comprehensive line of restaurant rated exhaust fans from up blast and utility sets to efficient inline options. Fully integrated ventilation systems that results in positive, balanced buildings where customers and employees prefer to dine and work. FEATURES A complete high quality modular system for your kitchen High Profile Centrifugal Blowers make sure elevated smoke extractions Ducts are neatly fabricated Available in various size according to customer need Instant result oriented equipment Highly durable

Scroll Compressor Chiller

80,000 Per Piece

1 Piece (MOQ)

Flameproof HVAC

650,000 - 1,400,000 Per Nos

1 Piece (MOQ)

DewSat specializes in the engineering and manufacture of Explosion Proof, Corrosion Resistant, and Severe Duty HVAC/R systems and Pressurization Equipment. Our explosion proof, severe duty systems are designed to offer a safe solution at a competitive price. We strive to maintain the highest level of quality in both our systems and services. Designed for Explosive atmosphere, Like Zone 1 & 2 Designed for Groups IIA, IIB or IIC. Designed for sites with explosive atmosphere, such as petroleum exploitation, refinery, storage, chemistry, medicine, military facilities, etc. Efficient energy saving and low noise. Single refrigeration type and refrigeration & heating type. CAPACITY: 1TR TO 25TR Technical consideration for HVAC system design: Self‐contained & packaged unit or central system. Outside and inside temperature and humidity, Volume of space to be conditioned. Equipment and/or people contained in the space to be conditioned. Refrigeration type, Compressor type, cooling capacity. Heating resource, Heating method, Cooling medium, Air flow External static pressure,External and internal pressure difference

02 TR Air Cooled Chillers

89,500 Per

Steel Commercial Air Cooling System

102,000 Per Piece

Air Cooled Condenser

Get Price Quote

Air cooled condenser is a heat-exchange system. Conversely, the vapour can be fed through the tubes with the coolant water or air flowing around the outside. Air cooled condenser, the coolant flows through the tube side and distilled vapor through the shell side with distillate collecting at or flowing out the bottom.Air cooled condenser are also used in industrial-scale distillation processes to cool distilled vapor into liquid distillate.

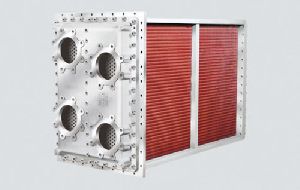

Fin Fan Coolers

Get Price Quote

The Air Cooled Heat Exchangers are also known as Fin fan Coolers. Fin Fan Cooler is nothing but traditional name of Air Cooled Heat Exchanger. Since Fins are used in the Cooler it is called as Fin fan Cooler. Please refer Air cooled Heat Exchanger for all the details. In the Fin fan coolers, the ambient air is used as the cooling media to cool. the main hot fluid which is used in tube side. All the tubes used in the coolers are finned tubes only. The finned tubes are having more contact surface , hence the fin fan cooler is one of the best closed circuit and water savable cooling system.

Air Fin Coolers

Get Price Quote

Air cooled Heat Exchangers manufactured and supplied by us are also known as air fin coolers. We manufacture these heat exchangers with excellent quality raw materials. Our air fin coolers successfully reduce the temperature of the circulating fluid inside the finned tubes by pushing air over the tubes. We customize the air cooled heat exchangers as per the client’s requirements and needs.The finned tube bundles in the exchanger are provided by us in modular construction so that it is easy to transport. The types of headers offered by us are Plug Header, Manifold header, Welded Bonnet Header, Plug and pipe header etc. ‘G’ type Embedded Fins, ‘L’ type Wrap-On Fins, and Bi-metallic Extruded Fins are some of the fin types offered by us to the customers. We are offering these exchangers at affordable prices. Features: Durable structure Less maintenance High quality and efficiency Long service life

Evaporator Cooling Systems

Get Price Quote

An evaporative cooling system offers effective cooling by combining water evaporation, which is a natural process, with a reliable and simple air-moving system. Air from the outside is pulled via moist pads where evaporation cools it and is circulated in a building or a house with the help of a large blower. During this process, the temperature of the air in the outside gets reduced as much as thirty degrees. Compared to the conventional systems, the fill type system attains maximum saturation. The design is compact and pre-fabricated, consumes less space, which is only about forty percent of that occupied by conventional systems. There is no requirement for masonry work and can be placed outside the building too. Consumption of power is negligible when compared to spray machines. This is due to low drop in pressure and low pump. The level of maintenance is also negligible since no nozzles are used. This promises trouble-free service. Since there are no nozzles of high pressure, the noise level is only about eighty decibel near the machines. Quick installation ensured as the machine is fabricated and tested at factory and possesses the flexibility for relocation. The equipments are available in FRP casings or stainless steel. The content material at the surface is specially engineered for the pupose of direct evaporative cooling & humidification. It is constructed from a unique cellulose paper that comes impregnated with compounds that are insoluble and prevent rotting. It also contains wetting agents and stiffening saturates. The material is made out of corrugated sheet that is assembled in pads that are self supporting. There is an arrangement of patented angle on the sheets in order to direct the flow of water towards the side of the air inlet, the place of occurrence of maximum evaporation. The pad is also constructed to flush away the dust from the atmosphere and has a contact surface of about 440 m2/ m3 between water and air. The cover of water distribution is of fiber glass reinforced plastic for its anti corrosive properties. The metal parts are of sixteen guage steel sheet that is galvanized. The water tank is of 3 mm frp that is of reinforced steel. Benefits of Evaporative Cooling System With the latest awareness on energy efficiency, evaporative cooling systems are gaining a lot of popularity Owing to the simple technology employed, the cost of the evaporative cooling system is cheaper The systems operate on 120V electricity which implies that they don't require special circuits of high-amperage unlike many air conditioners. It could be plugged into an outlet nearby The air gets moisture as a result of evaporative cooling. This helps in preventing the drying out of fabrics and wood furniture. The moist pads are good air filters and thus trap some pollen and dust. As the pads are kept wet, the trapped particles get flushed and caught in the cooler bottom. Not much of ductwork is needed in evaporative cooling systems. For a system that is newly installed, a short duct helps to direct the air that is cooled to the building's central point.

Water Cooled Chiller

Get Price Quote

We are offering chiller, chilled water is used to cool and dehumidify air in mid to large size commercial, industrial facilities like water chillers can be either water cooled chiller or air cooled chiller whenever a chiller's heat rejection can be used for a productive purpose, in addition to the cooling function. air cooled chillers are intended for outdoor installation and operation. Air cooled machines are directly cooled by ambient air being mechanically circulated directly through the machine's condenser coil to expel heat to the atmosphere.

Guillotine Damper

Get Price Quote

multi louver dampers

Fruits Condenser

Get Price Quote

With the aid of skillful professionals, we present a comprehensive range of Fruits Condenser. This product is available in diverse configurations. This product is extremely utilized by our customers for their top performance and longer service life. Our provided range of products is examined on definite quality parameters before its dispatch. We offer various models of products to suit dissimilar necessities of the customers. Features: Compact construction Longer working life High strength

charge air coolers

Get Price Quote

A charge-air cooler is simply an all-encompassing term, meaning that it cools the turbo's air charge before it is routed into the engine. Usually a charge-air cooler means an air-to-air cooler where the heat is rejected using ambient air flowing through the heat exchanger, much like the engine's coolant radiator. In general, an intercooler or aftercooler is said to be a Charge-Air Cooler.

Upvc Ventilator Louver

400 Per Square Feet

Air Cooled Condenser

Get Price Quote

We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plants.In systems involving heat transfer, a condenser ( Air Cooled Condenser )is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers. Specifications : A condenser unit used in central air conditioning systems typically has a heat exchanger section to cool down and condense incoming refrigerant vapor into liquid, a compressor to raise the pressure of the refrigerant and move it along, A fan for blowing outside air through the heat exchanger section to cool the refrigerant inside. Applications : A typical configuration of such a condenser unit is as follows: The heat exchanger section wraps around the sides of the unit with the compressor inside. In this heat exchanger section, the refrigerant goes through multiple tube passes, which are surrounded by heat transfer fins through which cooling air can move from outside to inside the unit. Advantages : There is a motorized fan inside the condenser unit near the top, which is covered by some grating to keep any objects from accidentally falling inside on the fan. The fan is used to blow the outside cooling air in through the heat exchange section at the sides and out the top through the grating. These condenser units are located on the outside of the building they are trying to cool, with tubing between the unit and building, one for vapor refrigerant entering and another for liquid refrigerant leaving the unit. Of course, an electric power supply is needed for the compressor and fan inside the unit.