Water Cooled Chiller

Get Price Quote

Water Cooled Chiller, which we offer, is manufactured, using world-class scroll compressors that are from Copeland and Danfoss-Maneurop. These Water Cooled Chillers are absolutely Microprocessor Based, making them suitable for any type of processing cooling applications ranging from (+) 20oC to (-) 15oC. Any type of applications demanding working in temperature up to (-) 50oC, refer Brine Chillers. We offer the best sources to get premium Water Cooled Chillers. Highlights CFC Free Refrigerant R- 407CNozzle sizes are at the chiller inlet / outlet.Bigger pump, if chosen, can be located within the chiller, only if possibleStepwise Capacity Control (20%, 50% & 75%)PLC Based Control without Communication. Bigger capacity tank, if chosen, will be external Design Conditions Connected Power 415V AC +/- 10% / 50Hz / 3 Phase + NeutralDesign Condensing Temperature (+) 40oC Design Evaporating Temperature (+) 5oC

JC Air Cooled Condenser

Get Price Quote

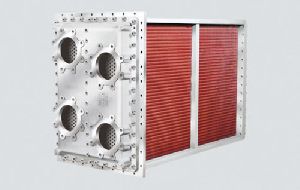

JC Equipments are certified ISO and ASME (The American Society of Mechanical Engineers) company with 23 years experience in Heat Exchanger Industry. We are manufacturing of heat exchangers since 1990. JC Equipments are speacially designed and developing of Air Cooled Condenser for all types of Thermal Power plants and indusries, Oil Plants and Gas Plants. JC has the good quality manufacturers and installing capability to supply the most excellent air cooled condenser for every applications. Air Cooled Condensers Types are : Natural Convection and Forced Convection. Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Best Deals from Air Conditioning System

Air Cooled Condenser

Get Price Quote

Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Air Cooled Condenser

Get Price Quote

The manufacturing of air cooled condenser is made of modules arranged in parallel rows as like air cooled heat exchanger. The air cooled condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. If your air cooled condensers (acc) are not operating at their optimum they are losing money. by using tube tech international’s innovative air cooled condenser cleaning service lower production rates, higher mechanical costs, higher maintenance costs plus lost time in both machinery and manpower will be problems of the past. Air cooled condenser tube cleaning with specialist industrial cleaning will make a huge difference to your operation. You will increase performance, improve safety, reduce your carbon emissions and reduce overall downtime the major benefits of air cooled condenser are: elimination of additional water usage from the condensing power cycle flexibility in power plant site selection decreased time required for plant permitting the fin tube is the core technology of the air cooled condenser. single-row condensers (src) - an elongated, flat tube with brazed aluminum fins. multi-row galvanized (mrc) - an oval tube with hot-dip galvanized steel fins.

Air Cooled Condenser

Get Price Quote

The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design.

Bare Tube Evaporator

10,000 - 30,000 Per Piece

1 Piece (MOQ)

Mild Steel Condenser

Get Price Quote

textile humidification system

Get Price Quote

We are the most promising name, involved in supplying textile humidification system. Ours is a well-established firm located in Coimbatore(India) and engaged in the business of providing a wide assortment of quality products.

Finned Evaporator

Get Price Quote

Finned Tube can also be suitable for liquid cooling applications. Copper is specified in supply and return manifolds and in tube coils. Finned Tube heat exchangers are most commonly used for forced air heating and cooling systems, such as with indoor and outdoor wood furnaces, boilers, and stoves.

Air Cooled Condenser (acc)

Get Price Quote

The gireesh is a well known manufacturer of a high quality range of Air Cooling Condenser which are high on demand in the market and they can be got customized by the clients as per their requirements. These products are made using advanced technology and they offer a high performance to the customers. They are easy to install and consume a very low amount of electricity. These products are very durable and offer a long lasting service life to the customers Gireesh Process cooling with air as cooling medium is used successfully in many industry branches. With steadily increasing costs for cooling water it also becomes more and more important in the power industry. At locations where cooling water is not available it is often the only possibility for the cooling of process streams.

Fruits Condenser

Get Price Quote

With the aid of skillful professionals, we present a comprehensive range of Fruits Condenser. This product is available in diverse configurations. This product is extremely utilized by our customers for their top performance and longer service life. Our provided range of products is examined on definite quality parameters before its dispatch. We offer various models of products to suit dissimilar necessities of the customers. Features: Compact construction Longer working life High strength

Air Fin Coolers

Get Price Quote

Air cooled Heat Exchangers manufactured and supplied by us are also known as air fin coolers. We manufacture these heat exchangers with excellent quality raw materials. Our air fin coolers successfully reduce the temperature of the circulating fluid inside the finned tubes by pushing air over the tubes. We customize the air cooled heat exchangers as per the client’s requirements and needs.The finned tube bundles in the exchanger are provided by us in modular construction so that it is easy to transport. The types of headers offered by us are Plug Header, Manifold header, Welded Bonnet Header, Plug and pipe header etc. ‘G’ type Embedded Fins, ‘L’ type Wrap-On Fins, and Bi-metallic Extruded Fins are some of the fin types offered by us to the customers. We are offering these exchangers at affordable prices. Features: Durable structure Less maintenance High quality and efficiency Long service life

Man Coolers

Get Price Quote

Man Coolers, electrical cooler

Air Cooled Chiller

Get Price Quote

Chilled water is used to cool and dehumidify air in mid to large size commercial, industrial facilities like Water chillers can be either water cooled chiller or air cooled chiller Whenever a chiller's heat rejection can be used for a productive purpose, in addition to the cooling function. Water Cooled Chillers : Water cooled chillers are typically indoor installation and operation, it’s are cooled by a separate condenser water loop and connected to outdoor cooling towers to expel heat to the atmosphere. Air Cooled Chiller: Air Cooled chillers are intended for outdoor installation and operation. Air cooled machines are directly cooled by ambient air being mechanically circulated directly through the machine's condenser coil to expel heat to the atmosphere. Quality Control: Our chillers are compact design covering minimum floor area. low cost maintenance, break throw technology and long life serviceability Chilled water temperature can range from 1.5°C to 7°C We manufacturing chillers range from 0.5 TR to 250 TR Function Of Industrial Chiller The industrial chillers are normally packaged, complete and closed-loop systems Include the condenser, pumps, chiller, temperature control systems and associated valves. Circulates water or any other coolant at constant pressure and temperature. The coolant flows from the chiller to the point of application and back again. Refrigeration is used as the cooling process in most of the industrial chillers. Some depend on air or water that flows over the coils containing a specific coolant in order to regulate the temperature. The coolant that is used most commonly in process chillers is water, though coolant mixtures are employed frequently. The latest development in industrial water chillers is the utilization of water cooling rather than air cooling. The condenser cools the refrigerant with water and not air. A cooling tower cools the air, thus reducing the need for energy as well as the chiller size. This is because of the condenser's small surface area and the lack of cooling fans which minimizes the noise levels too. Industry Chiller Application Chilled water or other liquid from the chiller is pumped through process or laboratory equipment. Industrial chillers are used for controlled cooling of products, mechanisms and factory machinery in a wide range of industries like. Plastic industry in injection and blow moulding, Metal working cutting oils, welding equipment, Die-casting and machine tooling, chemical processing, Pharmaceutical formulation, Food and beverage processing, Paper and cement processing, Vacuum systems X-ray diffraction Power supplies and power generation stations, analytical equipment, compressed air and gas cooling. Target chiller used to cool high-heat specialized items such as MRI machines and lasers, and in hospitals, hotels and campuses. The chillers for industrial applications can be centralized, Decentral chillers are usually small in size (cooling capacity), usually from 0.2 tons to 10 tons. Central chillers generally have capacities ranging from 10 tons to 100 Specifications When determining industrial chiller specifications, the following aspects need to be taken into consideration: Source of power Chiller rating Capacity of the evaporator and condenser Cooling capacity of the chiller Type of the evaporator Ambient temperature Material of evaporator and condenser Type of fan Expectations of efficiency Materials of plumbing and piping Limits of noise level Number of compressors and their type Number of circuits Fluid leaving temperature Coolant requirements Type of refrigerant

Air Blower

Get Price Quote

Air Cooled Condenser

Get Price Quote

Air Cooled Condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. The Air Cooled condenser is made of modules arranged in parallel rows as like Air Cooled Heat Exchanger. The module contains number of Finned Tube bundle. The axial flow forced draft fan is fixed in the module and forces the atmospheric cooling air across the Condensate area of the fin tubes.

Air Cooled Condenser

Get Price Quote

We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plants.In systems involving heat transfer, a condenser ( Air Cooled Condenser )is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers. Specifications : A condenser unit used in central air conditioning systems typically has a heat exchanger section to cool down and condense incoming refrigerant vapor into liquid, a compressor to raise the pressure of the refrigerant and move it along, A fan for blowing outside air through the heat exchanger section to cool the refrigerant inside. Applications : A typical configuration of such a condenser unit is as follows: The heat exchanger section wraps around the sides of the unit with the compressor inside. In this heat exchanger section, the refrigerant goes through multiple tube passes, which are surrounded by heat transfer fins through which cooling air can move from outside to inside the unit. Advantages : There is a motorized fan inside the condenser unit near the top, which is covered by some grating to keep any objects from accidentally falling inside on the fan. The fan is used to blow the outside cooling air in through the heat exchange section at the sides and out the top through the grating. These condenser units are located on the outside of the building they are trying to cool, with tubing between the unit and building, one for vapor refrigerant entering and another for liquid refrigerant leaving the unit. Of course, an electric power supply is needed for the compressor and fan inside the unit.

charge air coolers

Get Price Quote

A charge-air cooler is simply an all-encompassing term, meaning that it cools the turbo's air charge before it is routed into the engine. Usually a charge-air cooler means an air-to-air cooler where the heat is rejected using ambient air flowing through the heat exchanger, much like the engine's coolant radiator. In general, an intercooler or aftercooler is said to be a Charge-Air Cooler.

Air Cooled and Water Cooled Chiller

Get Price Quote

We carry out installations, preventive, maintenance, servicing, anti becterial treatment and repair of both domestic and commercial air conditioning units and refrigeration equipments.

stainless steel water boiler

Get Price Quote

stainless steel water boiler, dosa plate burner, rice cooking vessel

Foundry Sand Cooler

Get Price Quote

Foundry Sand Cooler, Aluminium Air Oil Cooler, Bottle Shape Cooling Tower

Ac Condenser

Get Price Quote

Ac Condenser

Cooling Tower

Get Price Quote

Frp Square Type Cooling Tower, Frp Seemless Cooling Tower

humidification plants

Get Price Quote

humidification plants, inter coolers, fuel coolers

cooling systems

Get Price Quote

cooling systems, bulk material handling equipment

scroll chillers

1 Per -

cooling systems

Get Price Quote

cooling systems, bulk material handling equipment, general fabrication

fan coils

Get Price Quote

cnc winding machine, chocks, Transformers

car air conditioner fitting

Get Price Quote

car air conditioner fitting, Air conditioner, WASHING MACHINE

Square Diffuser

Get Price Quote

Linear Slot Diffuser, aluminum air grille