industrial air conditioning

Get Price Quote

Carrier and Voltas Chiller projects with AHUs, BCUs, FCUs, Primary, Secondary, Tertiary Pump installation, Chilled water pipings, Ducting, Testing and commissioning etc in India and Middle east...

Industrial Rooftop Solar Power System

Get Price Quote

1 Set (MOQ)

Solar Powertech Solutions is the manufacturer of Industrial Solar Rooftop Power System in Coimbatore. Our entire product range is durable in nature and is easy to install. Offered product range is available in different technical specifications and can be customized as per preference. We source the entire product line from the reliable manufacturer who has maintained a strong foothold in fabricating these products. Product Details: Cost is reimbursed within 5 to 6 years of installation Requires cleaning of SPV panels apart from this no other part require maintenance because of zero movability Systems offered on basis of quality and cost competency Noise free, Clean and Eco-friendly Minimal maintenance Simple installation Other Details: A 100 KW Capacity Roof Top system helps in saving 50,000 liters of diesel every year

Best Deals from Air Conditioning System

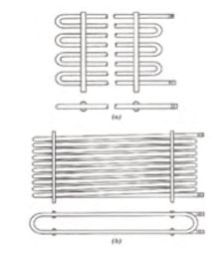

Shell and Tube Type Evaporator

30,000 - 80,000 Per Piece

1 Piece (MOQ)

Air Cooled Chiller

Get Price Quote

The Air Cooled Chiller, which we offer, is manufactured as per the set industrial standards and norms. We offer premium Air Cooled Chiller at competitive rates to the clients. We are among the reliable sources to get the best Air Cooled Chiller. Highlights Use special compressors from Copeland, Danfoss and Bitzer, having a capacity from 5TR up to 20TR with Single Compressor System Also, Multiple Compressor Systems are availableVaried range of Refrigerants available such as Freon R 22, R 404a, R 407c, R 507, R 134a, etc.Low NoiseLow VibrationLow Failure rateCompact modular design Maximum accessibility Total connectivityReliable and High Efficiency and High Performance Scroll Compressor Tropicalised design for high ambient temperatures up to 52 degree CBrazed Plate EvaporatorWide Choice of Capacities and EfficienciesEasy installationBetter part load efficiency with multiple compressorsPositive pressure designLower electrical infrastructure cost Available with heat pump application

Mild Steel Condenser

Get Price Quote

textile humidification system

Get Price Quote

We are the most promising name, involved in supplying textile humidification system. Ours is a well-established firm located in Coimbatore(India) and engaged in the business of providing a wide assortment of quality products.

air cooled scroll chiller

Get Price Quote

Water-cooled Screw Chillers are designed to work within extreme tropical zed weather conditions, while maintaining the highest energy efficiency. Designing and the choice of equipment are critical to conform to superior standards. Manufacturing and testing standards at our facilities are at par with the best, internationally. Installed equipments are operation friendly and are backed by competent engineering team to realize the advantage while being in operation. The Industrial Screw Chillers are designed and manufactured for the cooling processes, where each process is completely different from the other. The industrial chillers are designed using qualitative materials and metallurgy and are fitted with the most efficient compressors from Europe. The materials and metallurgies are chosen according to the process fluid being used as per the specific process requirements. Complete study of the process to ascertain peculiarity of the requirement, precedes the choice of equipment and accessories being proposed, through an engineering team with specific expertise. Salient Features Optimum selection of components for your application With evaporator options as immersed coil, plate type, shell, and coil Use of stainless steel tanks for corrosion free operation Digital controller for temperature control and fault indication High-efficiency heat transfer Low power consumption High-quality water pumps Refrigeration system and electrical safety devices

Fin Fan Coolers

Get Price Quote

The Air Cooled Heat Exchangers are also known as Fin fan Coolers. Fin Fan Cooler is nothing but traditional name of Air Cooled Heat Exchanger. Since Fins are used in the Cooler it is called as Fin fan Cooler. Please refer Air cooled Heat Exchanger for all the details. In the Fin fan coolers, the ambient air is used as the cooling media to cool. the main hot fluid which is used in tube side. All the tubes used in the coolers are finned tubes only. The finned tubes are having more contact surface , hence the fin fan cooler is one of the best closed circuit and water savable cooling system.

Finned Evaporator

Get Price Quote

Finned Tube can also be suitable for liquid cooling applications. Copper is specified in supply and return manifolds and in tube coils. Finned Tube heat exchangers are most commonly used for forced air heating and cooling systems, such as with indoor and outdoor wood furnaces, boilers, and stoves.

Fin Fan Coolers

Get Price Quote

The Air Cooled Heat Exchangers are also known as Fin fan Coolers. Since Fins are used in the Cooler it is called as Fin fan Cooler Specifications : The ambient air is used as the cooling media to cool the main hot fluid which is used in tube side. Applications : The finned tubes are having more contact surface. All the tubes used in the coolers are finned tubes. Advantages : This is one of the best closed circuit and water savable cooling system.

Air Cooled Chiller

Get Price Quote

Chilled water is used to cool and dehumidify air in mid to large size commercial, industrial facilities like Water chillers can be either water cooled chiller or air cooled chiller Whenever a chiller's heat rejection can be used for a productive purpose, in addition to the cooling function. Water Cooled Chillers : Water cooled chillers are typically indoor installation and operation, it’s are cooled by a separate condenser water loop and connected to outdoor cooling towers to expel heat to the atmosphere. Air Cooled Chiller: Air Cooled chillers are intended for outdoor installation and operation. Air cooled machines are directly cooled by ambient air being mechanically circulated directly through the machine's condenser coil to expel heat to the atmosphere. Quality Control: Our chillers are compact design covering minimum floor area. low cost maintenance, break throw technology and long life serviceability Chilled water temperature can range from 1.5°C to 7°C We manufacturing chillers range from 0.5 TR to 250 TR Function Of Industrial Chiller The industrial chillers are normally packaged, complete and closed-loop systems Include the condenser, pumps, chiller, temperature control systems and associated valves. Circulates water or any other coolant at constant pressure and temperature. The coolant flows from the chiller to the point of application and back again. Refrigeration is used as the cooling process in most of the industrial chillers. Some depend on air or water that flows over the coils containing a specific coolant in order to regulate the temperature. The coolant that is used most commonly in process chillers is water, though coolant mixtures are employed frequently. The latest development in industrial water chillers is the utilization of water cooling rather than air cooling. The condenser cools the refrigerant with water and not air. A cooling tower cools the air, thus reducing the need for energy as well as the chiller size. This is because of the condenser's small surface area and the lack of cooling fans which minimizes the noise levels too. Industry Chiller Application Chilled water or other liquid from the chiller is pumped through process or laboratory equipment. Industrial chillers are used for controlled cooling of products, mechanisms and factory machinery in a wide range of industries like. Plastic industry in injection and blow moulding, Metal working cutting oils, welding equipment, Die-casting and machine tooling, chemical processing, Pharmaceutical formulation, Food and beverage processing, Paper and cement processing, Vacuum systems X-ray diffraction Power supplies and power generation stations, analytical equipment, compressed air and gas cooling. Target chiller used to cool high-heat specialized items such as MRI machines and lasers, and in hospitals, hotels and campuses. The chillers for industrial applications can be centralized, Decentral chillers are usually small in size (cooling capacity), usually from 0.2 tons to 10 tons. Central chillers generally have capacities ranging from 10 tons to 100 Specifications When determining industrial chiller specifications, the following aspects need to be taken into consideration: Source of power Chiller rating Capacity of the evaporator and condenser Cooling capacity of the chiller Type of the evaporator Ambient temperature Material of evaporator and condenser Type of fan Expectations of efficiency Materials of plumbing and piping Limits of noise level Number of compressors and their type Number of circuits Fluid leaving temperature Coolant requirements Type of refrigerant

Water Cooled Chiller

Get Price Quote

We are offering chiller, chilled water is used to cool and dehumidify air in mid to large size commercial, industrial facilities like water chillers can be either water cooled chiller or air cooled chiller whenever a chiller's heat rejection can be used for a productive purpose, in addition to the cooling function. air cooled chillers are intended for outdoor installation and operation. Air cooled machines are directly cooled by ambient air being mechanically circulated directly through the machine's condenser coil to expel heat to the atmosphere.

air conditioner chiller

Get Price Quote

We are leading manufacturer of Chiller in india, and also we offer a full range of chiller services, installation. JC Equipments having 23 years of experience and in all industrial cooling applications and High quality design by our designing teams.The chiller with the aim of removes the heat from a liquid via a absorption refrigeration cycle and chiller is mostly used in heat processing industries. Vital parts of Air Conditioning Units are, Compressor, Condenser and Evaporator. Air Conditioner Chiller Works It's impossible to understand with air conditioner chiller works. The air conditioner's chiller Components are condenser and evaporator. They are moreover as well-known as the heat exchanger units and also the chilling system is able to integrated with supplementary heating systems such as boilers and solar panels and others. Chiller Applications The chiller is used in following industries, Plastic industry, Power Generation Plants Welding Plants Chemical Processing Industries Food Processing Units Ssemiconductors, Cement Industries Power Generation Plants Compressed air and gas cooling.

Humidification Plant

10,000 Per Piece

Air Blower

Get Price Quote

Air Cooled Condenser

Get Price Quote

We are leading manufacturers and suppliers, exporters of air cooled condenser in india and the condenser types are Natural Convection,Forced Convection and also manufacture the Water cooled condenser. Coal based and All Thermal power plants, Solar Power Plants, Nuclear power plants, Gas Based Power Plants.

Air Cooled Condenser

Get Price Quote

Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

mixed humidification system

Get Price Quote

Air Cooled Condenser

Get Price Quote

The manufacturing of air cooled condenser is made of modules arranged in parallel rows as like air cooled heat exchanger. The air cooled condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. If your air cooled condensers (acc) are not operating at their optimum they are losing money. by using tube tech international’s innovative air cooled condenser cleaning service lower production rates, higher mechanical costs, higher maintenance costs plus lost time in both machinery and manpower will be problems of the past. Air cooled condenser tube cleaning with specialist industrial cleaning will make a huge difference to your operation. You will increase performance, improve safety, reduce your carbon emissions and reduce overall downtime the major benefits of air cooled condenser are: elimination of additional water usage from the condensing power cycle flexibility in power plant site selection decreased time required for plant permitting the fin tube is the core technology of the air cooled condenser. single-row condensers (src) - an elongated, flat tube with brazed aluminum fins. multi-row galvanized (mrc) - an oval tube with hot-dip galvanized steel fins.

scroll chillers

1 Per -

Air Cooled Condensers

Get Price Quote

Air Cooled Condensers, Air Cooled Heat Exchanger, Heat Exchangers

Foundry Sand Cooler

Get Price Quote

Foundry Sand Cooler, Aluminium Air Oil Cooler, Bottle Shape Cooling Tower

car air conditioner fitting

Get Price Quote

car air conditioner fitting, Air conditioner, Car Accessories

Ac Condenser

Get Price Quote

Ac Condenser, Condensers

humidification plants

Get Price Quote

humidification plants, Water Treatment Chemicals, Heat Exchangers

fan coils

Get Price Quote

fan coils, cnc winding machine, chocks, Transformers

stainless steel water boiler

Get Price Quote

stainless steel water boiler, dosa plate burner, rice cooking vessel

Man Coolers

Get Price Quote

Man Coolers, Desert Air Coolers, electrical cooler

cooling systems

Get Price Quote

cooling systems, bulk material handling equipment, Conveyor Rollers

Plate Chiller

Get Price Quote

Plate Chiller, Pressure Vessel, Chemical Reactors, Piping Systems