Animal Feed Grinding Cum Mixing Machine

55,000 Per Piece

1 Piece (MOQ)

Screw Bowl Feeder

180,000 Per Piece

1 Piece (MOQ)

Best Deals from Animal Feed Making Machine

Ribbon Blender

Get Price Quote

By using quality packing material, we make sure that the products are properly packed and there will be zero damage during transit. Moreover, our packaging experts stringently check the entire lot before making the final dispatch. As we remain much concerned about the safety of the products, we store the entire lot in our capacious warehousing unit under secured environment and expert's supervision. Features : High tensile strength Longer service life Robust construction

Ribbon Blender

100,000 Per Piece

1 Piece (MOQ)

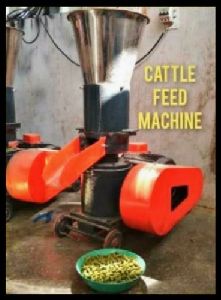

Cattle Feed Making Machine

59,999 Per Piece

1 Piece (MOQ)

pellet making machine

Get Price Quote

Mini Flat die Pellet Mil.Working principle of Pelletizing machine We are offering Pelletizing machine is one of the biomass molding equipment. It can make powdered biomass materials into pellets. The starting materials for the production of pellets are pressed by the pressing roller in the matrix. Due to the pressure and friction in the matrix, the starting materials are heated to a high temperature (nearly 60~80 °C). As a result of pressure and temprerature increasing, the materials were compressed into pellets. The output pellets will have very high strength after cooling. Wood pelletizing machine Wood pelletizing machine is mainly used for wood, straw, cotton stalk, rice husk, peanut shell, bamboo, empty fruit bunch, pulverized coal or waste paper, ect. There are two kinds of wood pelletizing machine: ring die & flat die. Advantage of our wood pellet machine is structure closely, easy to use, run stably; Advantages of output pellets is high density, high fuel value, low moisture and low ash content. Our ring die wood pelletizing machine are VPM series. Automatic lubrication system. Feed pelletizing machine is mainly used for making animal feed pellets. Corn, bean pulp, straw, grass, rice husk, alfalfa, wheat stalk, ect. Applicable industry: aquiculture, poultry feed making plant, stock farm, poultry farm, ect. There are two kinds of feed pelletizing machine: ring die & flat die.

Hammer Mill

30,000 Per Piece

With the assistance of our skilled and experienced workforce, we have been able to Exporter, Importe..With the assistance of our skilled and experienced workforce, we have been able to Exporter, Importe....

Heavy Duty Ribbon Blender Machine

Get Price Quote

1 Piece (MOQ)

rice mixer

Get Price Quote

Hammer Mill

600,000 - 700,000 Per piece

1 1 (MOQ)

Product includes Hammer mill, Screw conveyor, Shifter & Blender.

Ribbon Blenders

Get Price Quote

To furnish the diverse requirements of our clients we are involved in offering a wide range of Ribbon Blenders. These are made using optimum quality materials, which are procured from authentic vendors of the industry. Offered Ribbon Blenders are widely used for mixing various ingredients and materials. Our products have high tensile strength and well known for their dimensional accuracy. Apart from this, we also assure to deliver a defect free range of our products in a fixed time frame. Features: Exquisite design Fine finishing Affordable prices

pellet making machine

64,000 Per Piece

Ribbon Blender Mixer machine

60,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

Ribbon blender batch mixer for mixing all type of materials like eg: feed materials, food materials, fertilizers, etc,

Ribbon Blender

Get Price Quote

The ribbon blenders are an extraordinary creation. Ribbon blender’s main purpose is attained by the fine and thorough blending of powders with powders/liquids (upto 40%) with powders. The working principle of the ribbon blenders involve two mutually opposite turned ribbons are working at a very low rpm on horizontally mounted shaft inside the ‘U’ trough, which pushes, lifts, throws and splashes the raw material inside the mixing vessel. Ribbon blender vessels are provided with a leak proof lid, top grill as a feed guard, motor, gear box and an MS frame. Apart from this the contact parts are fabricated in SS. Ribbon Blenders are mainly used for blending powders of similar physical properties. It is widely used in : (a)Spice Powder Industries (b)Instant Tea/Coffee (c)Medicine Manufacturers (d)Feed Industries (e)Chemical Industry Main parts of the machines are top hinched lid, hinched safety grill for feeding,' U'trough left and right ribbons leak proof gland packing, motor, reduction gear box bearing assembly, bottom discharge shutter and frame. After thorough blending the product is discharged at the bottom shutter. Ribbon blenders are available in sizes from 10 kgs to 3000 kgs.The ribbon roasters are highly useful to grind curry powder, rice flour, health mix, cattle mix and soy powder. The maintenance of these ribbon roasters are quite simple and does not require much labour. “Blended material are fine once blending process is done through Ribbon Blender...”

Hammer Mills

Get Price Quote

Some pellet plants start their process by putting large pieces of wood through a chipping machine for processing. These are only necessary for mills that accept this non-uniform feed stock. There are many different configurations to pellet manufacturing plants depending on their raw material source. While they all don't have chippers, almost all of them have a hammer mill at the beginning of their milling process. These machines take sawdust and wood chips and break them down into a consistent smaller size, making drying and pressing through the pellet die quick and consistent.

Hammer Mill

Get Price Quote

Ribbon Blenders

Get Price Quote

We are Supplier of this product.

Ribbon Blender

78,000 Per

1 Piece (MOQ)

SCREW FEEDER

Get Price Quote

Overview: In the case of conveying of bulk materials which has material characteristics like free flowing by nature, which packs under pressure, which are very light and fluffy i.e., may be windswept and materials with very high temperature, in such cases belt feeders are not suitable ; only Screw Feeder are recommended. The Gravimetric Screw Feeder is custom engineered compact, enclosed and eco-friendly equipment that finds applications in continuous bulk proportioning of solids. This gravimetric feeder operated by a closed loop control system enables feeding at a controlled rate and exercises precise control over rate of flow. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in cement, fertilizers and chemical industries. Each system consists of control panel, local panel, loadcell to measure the instantaneous load, tacho to sense the speed of the screw which is mounted inside closed trough. The screw shaft is driven by a constant speed AC motor coupled through a gear box.