Sand Casting

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed. Sand casting is used to produce a wide variety of metal components with complex geometries like Automotive, Engineering and Other Industries.

...more

Aluminium Pressure Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. The company having its Pressure Die-casting unit and manufacturing a wide range of Aluminum Pressure Die Casting Components for various Industries in and around Coimbatore. At Present we are manufacturing and supplying the following components for a Leading Tractor Manufacturer. T 3 Rocker Cover V.W.H. Rocker Cover Idle Pulley

...more

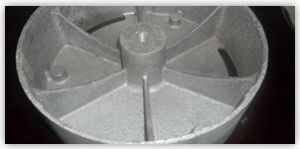

Aluminium Gravity Die Casting

The company having its own Non-ferrous and Aluminium Gravity Die-casting unit & manufacturing wide range of Aluminum Die Casting Components for various Industries. At Present we are manufacturing and supplying the following components for a Leading Tractor Manufacturer. Air Intake Manifold V.W.H. Air Intake Manifold Leaner Governor Assembly

...more

T3 Rocker Cover

High Pressure Aluminium Die Casting

Sand Mould Aluminium Castings

Four Cylinder Cover

Be first to Rate

Rate This