Automatic Oil Filter Press

Get Price Quote

1 Piece (MOQ)

The oil filter press is any easy to operate, safe and inexpensive piece of equipment to help filter impurities out of edible oils. An oil filter press can be built to food grade specifications.

Pp Filter Press

400,000 Per Piece

Best Deals from Cast Iron Filter Press

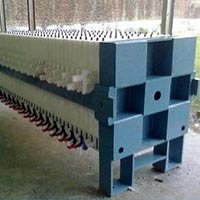

Pp Filter Press

Get Price Quote

The filter press is a solid liquid separation device using the principle of pressure feeding. It has been used successfully in almost every industrial filtration application . We are designed in such a way to give maximum filtration efficiency and less maintenance throughout its service life.

Filter Press

80,000 Per Piece

1 Piece (MOQ)

Cast Iron Filter

190 Per Piece

500 Piece (MOQ)

Filter Press

100,000 Per Piece

Filter Plate

75,000 Per Piece

Filter Press With Closing Devices

Get Price Quote

We provide Filter Press With Closing Devices, that has several modes of operation and is manufactured using high grade material. The Filter Press With Closing Devices comes with a variety of optional features that further enhance the efficiency of the equipment. Closing Devices : Ratchet GearManual HydraulicPower Hydraulic

Manual Filter Press

Get Price Quote

We manufacture a cost effective and highly efficient manual filter press which is available in 305mm (12") to 915mm (36") plate sizes. These machines are an effective, inexpensive choice for handling smaller quantities of material. This manually operated filter press with ratchet closing device consists of ratchet mechanism, pinion and gear wheel. By applying a ratchet lever to the pinion shaft the force is transmitted by small pinion to the larger gear-wheel which provides the final lightening on the plate pack. Applications: apply to solid-liquid separation process in petroleum, chemical, dyestuff, medicine, food, sewage treatment and other industries. Closing and opening of the filter press is manual cake discharge is manual cheaper in cost closing plates are shifted manually.

Automatic Filter Press

Get Price Quote

Plate shifting device shifts individual plates immediately after the filter press opens (i.e. After the moving end head is retracted) operated by hydro-motor with necessary chain and sprocket design. The system is along with the plate shaking mechanism which shakes the plates to the nos. Of time which helps cake to be de-loaded from the chamber. Shifter trolley will be of m.s. Construction. Necessary controls for speed and pressure are incorporated in the hydraulic power pack unit. The panel is designed to operate the plate transport system after the filter press opening.

sludge filter press

1,750,000 Per unit

Cast Iron Filter Press

900,000 Per Piece

1 Piece(s) (MOQ)

Fully Automatic Filter Press

Get Price Quote

1 Piece (MOQ)

We offer Fully Automatic Filter Press. products details : we manufacture fully automated advanced filter press with plate shifting & plate shaker for autocake discharge along with plc based electrical control panel & pneumatically opereated control valves, flow sensor and hydraulically operated bomb door drip tray. In this filter press initial filtration process takes place with the push of a button. Operator initiates filtration. Slurry is pumped into all chambers and cakes are formed as filtrate begins to flow. The end of filtration phase is automated by flow meter which is located on filtrate discharge pipe. The flow meter indicates the minimum flow rate of filtrate which is strictly related to the end of a cycle, the opening of filter press and the discharging phase a plate vibrating device during the discharge phase ensures 100 pct release of the cake. A plc controls the phases and cycle times for all the filter press functions including operation of the ancillary equipment. special features: 1-zero downtime 2-saves 95.7 % of labour cost. 3-achieve final solid consistency at outlet upto 76.2%. 4-short cycle time : 8 to 30 minutes. 5-less capital expenditure : filter press & dryer can be planned smaller 6-lower pollution control cost. 7-increased product yield 8-improved process economy 9-reduced space requirement. 10-fully automatic cycle. 11-manual mode option. 12-plc based controls 13-upto 2000 x 2000mm plate size 14-vibration system for cake drop 15-drip tray system application: excellent for etp-plants, granites, marble & ceramic industries, gypsum, bentoite, crystalline salts, pigments, dry precipitates, sludges generated from galvanizing plants containing chromium, zinc, aluminium, copper, nickel or cadmium,and many more. range of capacities and filtration areas: filtration areas range from 5 sq.mts to 100 sq mts and capacities from 0-1 to 125 tonnes of dry solids per hour. sha hydraulics private limited manufactures fully automated filter press by incorporating corner feed plates into its filter press design. Eliminating center-feed eyes and stay bosses removed restrictions to membrane movement and consistently produces more uniformly squeezed cake. A more uniform cake, in combination with newly developed filter fabrics, allows easy discharge of the cake from the plate. in this fully automated filter press simple cake removal system available with conventional fixed-volume, recessed-chamber plate filter presses, allows sha hydraulics private limited to automate your filter press. Our automated filter press includes a programmable logic controller (plc) and can be supplemented with a local control panel, crt, or touch-screen panel.

Fully Automatic Filter Press

Get Price Quote

We are providing our clients with the best-in-class gamut Fully Automatic Filter Press. Fabricated by making use of supreme quality basic material and components, these offered presses conform to the defined parameters of the industry. Furthermore, these offered products are highly appreciated for their remarkable attributes such as longer service life, resistance against corrosion, performance and compressive strength. Our clients can avail the offered products in both customized and standard forms as per their requirement. These offered products are provided with conventional fixed-volume, recessed-chamber plate filter presses, programmable logic controller (PLC) and can be supplied with a local control panel, CRT and touch-screen panel. Features: Zero downtime Saves 95.7 % of labour cost. Achieve final solid consistency at outlet up to 76.2%. Short cycle time: 8 to 30 minutes Less capital expenditure Filter press & dryer can be planned smaller Lower pollution control cost Increased product Yield

Oil Filter Press

405,000 Per Piece

air line filter

2,000 Per Piece

Sludge Dewatering Filter Press

Get Price Quote

We are offering sludge dewatering filter press.the sludge dewatering is a physical unit operation that reduces the water content in the sludge. Through a filter press, the sludge is dewatered due to the pressure applied; the resulting matter has a solid content of 25% or more.

Filter Press

100,000 Per unit

1 unit (MOQ)

Filter Press

Get Price Quote

Filter press is a separation process, specially employed by solidliquid separation using the principle of pressure drive, provided by a slurry pump. Filter press is a fixed volume and batch operation, which simply means that the operation must be stopped to discharge the filter cake before the next batch can be started.[1] The major components of filter press are skeleton and filter pack. The skeleton holds the filter pack together while pressure is being developed inside filter chamber. It however can only hold a specific volume of solids.

Hydraulic Filter Press

Get Price Quote

InfodirectoryB2B .com is an emerging online B2B marketplace for Small & Medium Size Businesses, connecting global buyers with suppliers. The company offers a platform & tools to suppliers to generate business leads from global buyers, who use the platform to find reliable & competitive suppliers.