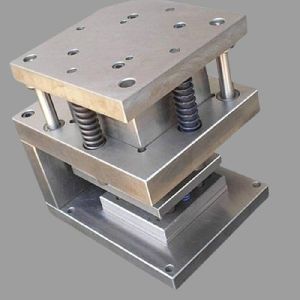

Press Tool Dies

35,000 - 50,000 Per Piece

1000 Piece (MOQ)

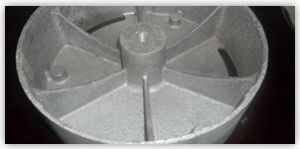

Aluminium Pressure Die Casting

80 - 10,000 Per Piece

100 Piece(s) (MOQ)

Aluminium Die Cast Rotors for -Motors -Pumps & Rotational equipments

Best Deals from Die Casting

cast iron castings

Get Price Quote

We are dedicatedly engaged in providing a wide array of Cast Iron Castings. Due to features like high durability, low maintenance and fine quality, our Cast Iron Castings are widely demanded in cement, chemical, engineering and automotive industries for various applications. Due to the low melting point, castability, good fluidity, resistance to deformation and wear, Cast Iron Castings are used as engineering material and in machines, pipes, automotive industry parts, etc. Cast Iron Castings are resistant to destruction and oxidation as well. Highlights : Sturdy construction Highly durable Low maintenance Corrosion resistance

Sand Casting

Get Price Quote

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed. Sand casting is used to produce a wide variety of metal components with complex geometries like Automotive, Engineering and Other Industries.

Casting Components

Get Price Quote

We have gained expertise in retailing and wholesaling a wide range of casting components.

Gravity die casting

Get Price Quote

Some of the products made using Gravity Die casting process are Housings, Junction boxes, impellers, Valve bodies, Flanges, Manifolds, Actuator bodies, Compressor parts, Electrical fittings parts, Covers. Permanent mould casting get their name from the fact that the process utilizes permanent metal moulds instead of temporary sand moulds for the casting process. Cast iron is the most commonly used mould materials as it offers great reliability during casting. The cores are made from other metals or sand. The cavity surfaces of the moulds are coated with fine layers of materials that have good heat-resistant properties such as clay or sodium silicate. The moulds used in casting are pre-heated upto 200 ºC (392 ºF) before the molten metal is poured into the cast cavity. Casting has to be done with care in order to ensure that proper thermal balance in maintained throughout the casting process. This is done through a variety of ways including external cooling techniques using water or relevant radiation techniques.Permanent mould casting, while not offering the same level of design flexibility and ease pattern usage as Aluminium Sand Castings, it has the advantage of offering relatively lower design and development costs as well as production costs. At VJP, we have the expertise to undertake permanent mould castings of complex components of diverse application in various industries.

Aluminum Die Casting Parts

Get Price Quote

Pressure Vessels

Get Price Quote

Pressure vessels are used in a variety of applications in industries. Pressure vessels are designed to operate safely at a specific pressure and temperature. A vessel that is inadequately designed to handle a high pressure constitutes a very significant safety hazard. Because of that, the design and certification of pressure vessels is governed by design codes.

Pressure Die Casting Dies

Get Price Quote

Pressure Die Casting Dies, Plastic Injection Molds 3

cast iron match plates

Get Price Quote

cast iron match plates, aluminium pattern casting, Aluminium Pattern

Sand Casting

Get Price Quote

Sand Casting, Grey Iron Casting, Iron Castings

Pressure Die Casting

Get Price Quote

Pressure die casting is a competitive casting method when the components are needed at high volumes or when better tolerances and surface finish are required .The need for machining is very low due to the close casting tolerances. Heat treatment of pressure die casting is not possible but due to the high rate of solidification the mechanical properties are good. The tooling costs are considerably higher than for gravity die casting.Pressure Die-casting is similar to permanent mold casting except that the metal is injected into the mold under high pressure . This results in a more uniform part, generally good surface finish and good dimensional accuracy, as good as 0.2 % of casting dimension. For many parts, post-machining can be totally eliminated, or very light machining may be required to bring dimensions to size.GowSai in association with UDC-coimbatore presents high quality range of high pressure die casting. We have 3 Horizontal Cold Chamber Pressure Die Casting Machine with each capacity of 120 tonne . We produce castings of weight ranging from 60 gms. to 600gms. The furnaces are individual holding and melting for specific alloy with necessary controls. At present we cast LM series alloys. Machines are replaced or upgraded regularly & the systems are ISO 9001 - 2000 compliant.

Sand Casting

Get Price Quote

Sand Casting, Grey Iron Casting, Gun Metal Valve, Aluminium Bronze Ring

Pressure Die Casting Tools

Get Price Quote

Pressure Die Casting Tools, Dies, Plastic Moulds, investment moulds

Pressure Die Casting

Get Price Quote

automobile product, pump products, aluminium moulded pieces

Divine Shirdi Saibaba Casting Ring

Get Price Quote

Divine Shirdi Saibaba Casting Ring, Ben Enamel Drops Stud, Kids Bengal Bangle

high pressure die casting

Get Price Quote

high pressure die casting, precision cnc machining

Pressure Die Casting Tool

Get Price Quote

Pressure Die Casting Tool, High Pressure Die Cast Rotor, plastic die maker

cast iron castings

Get Price Quote

steel grade castings, grade ci castings, Graded Ci Casting

cast components

Get Price Quote

cast components

gravity die casting component

Get Price Quote

gravity die casting component, casting pattern making, gravity die making

ductile iron casting components

Get Price Quote

ductile iron casting components, Motor Components

Die Castings

Get Price Quote

Die Castings, Castings

machine cast iron component

Get Price Quote

machine cast iron component, Precision Machined Component, Fly Wheels

Gravity Die Casting Components

Get Price Quote

One of the best Gravity Die Casting Components supplying company.

Aluminum Motor Housing Die

Get Price Quote

Aluminum Motor Housing Die, Aluminum Gun Metal Pattern, Disa Molding Jacket

rotor die casting

Get Price Quote

rotor die casting, Rotor

die casted parts

Get Price Quote

die casted parts, grinding components, press tool components

Pressure Die Casting

Get Price Quote

Die Castings, Plastic Injection Moulds, injection moulds components, Dies

Die Casting

Get Price Quote