Double Pipe Heat Exchanger

Get Price Quote

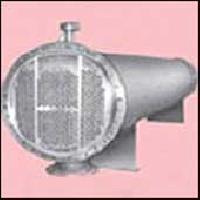

A double pipe heat exchanger, in its simplest form is just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface. The pipes are usually doubled back multiple times as shown in the diagram at the left, in order to make the overall unit more compact.

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger, in its simplest form is just one pipe inside another larger pipe. A hairpin heat exchanger may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. The wall of the inner pipe is the heat transfer surface. The pipes are usually doubled back multiple times as shown in the diagram at the left, in order to make the overall unit more compact. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes.

Best Deals from Double Pipe Heat Exchanger

Double Pipe Heat Exchangers

Get Price Quote

Double Pipe Heat Exchangers technologies are becoming more popular in modern air conditioning and refrigeration systems because they have better rates of heat transfer than conventional sized condenser and evaporator

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger, in its simplest form is just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface. The pipes are usually doubled back multiple times as shown in the diagram at the left, in order to make the overall unit more compact. The term ‘hairpin heat exchanger’ is also used for a heat exchanger of the configuration in the diagram. A hairpin heat exchanger may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. Types of Double Pipe Heat Exchangers :- 1. Counter flow2. Parallel Flow Heat Exchanger 1. Counter flow:-The main advantage of a hairpin or double pipe heat exchanger is that it can be operated in a true counter flow pattern, To get More Efficiency, In the mean Time, it will give the highest overall heat transfer coefficient for the double pipe heat exchanger design. 2. Parallel Flow:-Parallel Flow double pipe heat exchangers are focused to handle high pressures and temperatures applications. Also we can Achieve High Log mean Temperature using this. 3. Double Pipe Heat Exchanger Design:- Determination of the heat transfer surface area needed for a double pipe heat exchanger design can be done using the basic heat exchanger equation: Q = UA ΔTlm, where: Q is the rate of heat transfer between the two fluids in the heat exchanger in Btu/hr, U is the overall heat transfer coefficient in BTU/hr-ft2-oF,Remove term: A is the heat transfer surface area in ft2, and ΔTlm is the log mean temperature difference in oF, calculated from the inlet and outlet temperatures of both fluids. These parameters in the basic heat exchanger equation are discussed in ‘and they are used in an example in ‘ After determination of the required heat transfer surface area, the diameter and length of the inner pipe can be selected and then the diameter of the outer pipe. Finally, the length of the straight sections and the number of bends can be selected. Specifications : Some heat exchanger manufacturers advertise the availability of finned tubes in a hairpin or double pipe heat exchanger. These would always be longitudinal fins, rather than the more common radial fins used in a crossflow finned tube heat exchanger. Applications : A primary advantage of a hairpin or double pipe heat exchanger is that it can be operated in a true counterflow pattern, which is the most efficient flow pattern. It will give the highest overall heat transfer coefficient for the double pipe heat exchanger design. Advantages : Double pipe heat exchangers can handle high pressures and temperatures well. When they are operating in true counterflow, they can operate with a temperature cross. The cold side outlet temperature is higher than the hot side outlet temperature.

Double Pipe Heat Exchanger

Get Price Quote

Double Pipe Heat Exchangers A double pipe heat exchanger is one of the simplest form of Shell and Tube Heat System. Here, just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface. To make an Unit very Compact, The Arrangement is made Multiple Times and Continues Serial and Parallel flow. This is also called as a hairpin heat exchanger. These are may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. In some of the Special Cases the Fins also Used in Tube side. Types of Double Pipe Heat Exchangers 1. Counter flow and 2. Parallel Flow Heat Exchanger 1. Counter flow The main advantage of a hairpin or double pipe heat exchanger is that it can be operated in a true counter flow pattern, To get More Efficiency, In the mean Time, it will give the highest overall heat transfer coefficient for the double pipe heat exchanger design. 2. Parallel Flow Parallel Flow double pipe heat exchangers are focused to handle high pressures and temperatures applications. Also we can Achieve High Log mean Temperature using this. 3. Double Pipe Heat Exchanger DesignDouble pipe Heat Exchanger Thermal design is made based on Common Equation Q = UA ?Tlm After determination of the required heat transfer surface area, Other Mechanical Design are made, With reference to Process applications. The Design Process in Completely Simple Compare to All Other Heat Exchanger Design. 4. Construction and Standards:Before Construction we will have the Clear Discussion with our Customer, To select the Suitable Equipment, For a Customer Application. After Successful Analysis and Design We will submit our Valuable design with Suitable Drawings. We do Design and manufacturing of the heat transfer equipments as per the TEMA (Tubular Exchanger Manufacturers Association) ASTM Section (VIII) (unfired pressure vessels) BS, DIN Standards. And follows IS 2825, IS 6088, IS 4503, codes. We are capable to Construct the Hairpin Hear Exchangers in all Ranges based on Needs. It is an object of the invention to provide an inexpensive double-pipe heat exchanger having high performance and comprising an inner pipe and an outer pipe which constitute a double pipe without adding a heat-transfer facilitating material such as an inner fin. In the double-pipe heat exchanger having the inner pipe and the outer pipe, the outer pipe is dented from its outside toward its inside, thereby forming a plurality of projections which are dented toward the inner pipe.

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger is one of the simplest form of Shell and Tube Heat Exchangers. Here, just one pipe inside another larger pipe. To make an Unit very Compact, The Arrangement is made Multiple Times and Continues Serial and Parallel flow. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface.This is also called as a hairpin heat exchanger. These are may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. In some of the Special Cases the Fins also Used in Tube side.

Double Pipe Heat Exchanger

Get Price Quote

We are offering double pipe heat exchanger a double pipe heat exchanger is one of the simplest b forms of shell and tube heat exchangers. Here, just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface. To make a unit very compact, the arrangement is made multiple times and continues serial and parallel flow, features in double pipe heat exchanger design, an important factor is the type of flow pattern in the heat exchanger. A double pipe heat exchanger will typically be either counter flow or parallel flow. Cross flow just doesn't work for a double pipe heat exchanger. The flow pattern and the required heat

Double Pipe Heat Exchanger

Get Price Quote

The heat exchanger is completed of concentric inside also exterior pipe and the Heat exchangers are used to transfer the energy from one substance to another. Thermal design Calculation Q = UA ?TlmAfter determination of the required heat transfer surface area, Other Mechanical Design are made, With reference to Process applications. We JC Equipments Pvt Ltd Coimbatore India manufacturers of double pipe heat exchangers in India. A double pipe heat exchanger like Shell and Tube Heat Exchangers. We provide high and international quality standards double pipe heating system. We using latest raw material in the making development of double pipe heat exchangers.This type of heat exchangers are mostly used in the fields of Thermal Power Station, petroleum and Heat Industry, Oil and food Plants, Power Stations and etc. Counter flow and Parallel Flow Heat Exchanger Multi tube Double pipe exchangers Single tube Double pipe exchangers Countercurrent Double Pipe Heat Exchanger Double Pipe Hairpin Type Typical Double Pipe Heat Exchanger Double Pipe Heat Exchangers Applications JC Equipments are offering Double pipe for the below industrial application. Features of Double pipe heat exchanger: High Efficiency, International high quality, Low Maintenance Cost, Quick Heat Transfer. Double pipe heat exchanger Calculation: We are using most excellent softwares for support of complicated calculations while design of double pipe heat exchanger. Double pipe heat exchanger Design : JC Equipments Pvt Ltd used top rated softwares to design and best quality design engineers to design your double pipe heat exchanger. The heat exchangers are usually designed in a hairpin shape with ASME Code and will typically be either counterflow or parallel flow.1. ASME (American Society of Mechanical Engineers) ASME Code2. TEMA (Tubular Exchangers Manufacturers Association) Tubeside with High pressure Pasteurization Low allowable pressure drop Digester heating Heat recovery High flow rate ratios High terminal temperature differences. Pre-heating Its dependable and once-through Effluent cooling. Especially in cases of process-temperature crosses

Double Pipe Heat Exchanger

Get Price Quote

We are one of the major providers of Double Pipe Heat Exchanger manufacturers in india and the two types are Counter flow and Parallel Flow Heat Exchanger. The heat exchanger is one of the simplest form of Shell and Tube Heat Exchangers. This type of heat exchangers are mostly used in the following industries, Heat recovery Plants, Power Stations, and more industries.

Double Pipe Heat Exchanger

Get Price Quote

We are the leading manufacturer of double-pipe heat exchanger in india. The double-pipe heat exchanger is one of the simplest types of heat exchangers. It is called a double-pipe exchanger because one fluid flows inside a pipe and the other fluid flows between that pipe and another pipe that surrounds the first. This is a concentric tube construction. Flow in a double-pipe heat exchanger can be co-current or counter-current. There are two flow configurations: co-current is when the flow of the two streams is in the same direction, counter current is when the flow of the streams is in opposite directions. as conditions in the pipes change: inlet temperatures, flow rates, fluid properties, fluid composition, etc., the amount of heat transferred also changes. This transient behavior leads to 2 changes in process temperatures, which will lead to a point where the temperature distribution becomes steady. When heat is beginning to be transferred, this changes the temperature of the fluids. Until these temperatures reach a steady state their behavior is dependent on time. in this double-pipe heat exchanger a hot process fluid flowing through the inner pipe transfers its heat to cooling water flowing in the outer pipe. The system is in steady state until conditions change, such as flow rate or inlet temperature. These changes in conditions cause the temperature distribution to change with time until a new steady state is reached. The new steady state will be observed once the inlet and outlet temperatures for the process and coolant fluid become stable. In reality, the temperatures will never be completely stable, but with large enough changes in inlet temperatures or flow rates a relative steady state can be experimentally observed. advantage reliable closures for design pressures up to 15,000 psi (1055 kg/cm2) independent tube sheets for high-temperature differences, thermal shock and cycling. external split rings do not contact shell side fluid. all connections on the same end for ease of piping. moveable support brackets with slots for shell expansion and flexibility in installation. durable all welded baffle cage construction. all bolting is external. large radius u-bends for ease of cleaning and effective thermal expansion (no expansion joints)

Double Pipe Heat Exchanger

Get Price Quote

After determination of the required heat transfer surface area, Other Mechanical Design are made, With reference to Process applications. We JC Equipments Pvt Ltd Coimbatore India manufacturers of double pipe heat exchangers in India. A double pipe heat exchanger like Shell and Tube Heat Exchangers. We provide high and international quality standards double pipe heating system. We using latest raw material in the making development of double pipe heat exchangers.This type of heat exchangers are mostly used in the fields of Thermal Power Station, petroleum and Heat Industry, Oil and food Plants, Power Stations and etc.