dry coolers

Get Price Quote

dry cooler

Get Price Quote

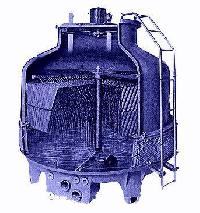

Cooling tower transfers heat from hot water to dry air by means of convection and evaporation and are often part of a total cooling package in combination with one or more of our heat exchangers. We can produce a complete turnkey system with the cooling tower, heat exchanger, water pumps, fan motor, fluid temperature controllers, variable speed fan drives, pressure and temperature gauges, automatic water treatment, all mounted on one galvanised skid needing only connection to power and water. The cooling towers are built with safety in mind as well as performance. Very low noise level cooling towers are available. Fan and Motor are mounted on the top of the frame. Fan has been dynamically balanced with the motor’s rotation RPM.In suction of air passing side fixed grid for security for finns . At the top of the area motor side fixed bird screen grid .

Best Deals from Dry Cooler

dry cooler

Get Price Quote

JC Equipments are designed and developed with to work with any size for various industries. Our Dry Cooling Tower designing department is routine updated with world standards according to the International Standards designing by CTI membership. Dry Cooling Tower Designing teams are technically qualified of engineer with facility to meet various application need.

dry cooler

Get Price Quote

The fluid coils of international standards are designed and selected through software providing accurate data on thermal transfer rate based on which they are manufactured. The tower designed incorporates the shell and tube designed with copper tubing and aluminium foil fins. The water losses are 0.01% since, the circuits are of the closed loop type and the towers are most space saving energy efficient once. They are best suited for applications such as Furnace coil water cooling, DG Sets, Compressors. The fans are of aluminium die cast with adjustable pitch and are individually tested for different flow rates. They are all dynamically balanced. Since, the complete fan is of Aluminium Alloy Plastic it does not corrode when used in out door applications. Dry cooling towers are in a single unit can be provided in capacities from 1000 kw to 1500 kw and they can be multiplexed to reach many thousand or kilowatts.

dry cooler

Get Price Quote

Predominantly used for air compressor and power generating units for applications of engine water cooling. Petroleum plant, power utility, steel manufacturing industry, cement, sugar factures , chemical and gas-processing industrials.There are no mobile parts except for the fan and the motors. Hence the cooling tower maintenance is negligible.

dry cooler

Get Price Quote

The main function of the offered dry cooling tower is to cool and maintain the temperature of process hot water at a particular level. The tower works on a principle of heat transfer and is driven by an electric motor. The wound copper tubes eliminate any unnecessary leakage after installation. The tubes also allow better heat transfer efficiency. The positive and controlled expansion between the tube and fin provides a clean, smooth inner tube surface for water pressure drop and guarantees uniform heat transfer. The rigid galvanized steel frame provides protection against tube damage during expansion and installation. Also, it is mounted on a heavy duty channel base frame. The axial flow fans are noise-free. The low speed of the motor minimises noise and increases efficiency. Motors are specially designed to withstand moisture, rain and dust.