Weighing Scale Hand Pallet Trucks

63,599 - 63,999 Per Nos

Our manufactured and supplied Weighing Scale Pallet Truck are well known in the market for their ergonomic design and high load carrying capacity. With the designing and fabrication being done in accordance with latest industrial norms, these products are highly robust, easy to use and possess effective functionality with maintenance free aspects. In addition to this, widely used in industries and warehouses for carrying cargo, these are offered to customers at competitive market rates. Specification: • Capacity: 2T• Division: 1kg• Fork dimensions:560*1160mm• Total dimensions:1245*1580mm• Weight units: Kg Features: • Easy entry:the fork of our easy entry makes the load of pallets easier.• With its battery charger and its removable battery system.it can operate without a break.• It fits in its steel structure(a good protection ),and allows you to receive data.• 4.Connecting without cables Optional: • Double data output: printer and RS232C• PR3 Printer or PR3W• RD-3W remote display. Specification: MODEL WT 20 Load Capacity (Kg/lbs) 2000 Loading Centre (mm) 520 Fork Length (L) 1150 Min. Fork height H1 80 Max. Fork height H2 200 Steering Wheels (mm) 180 x 50 PU (Polyurethane or Nylon) Fork Wheel (mm) 78 x 100 mm (Polyurethane or Nylon) Battery DC 12V, 5.0 Ah

Size : Load Capacity (Kg/lbs) 2000 Loading Centre (mm) 520 Fork Length (L) 1150 Min. Fork heigh

Brand Name : Fabtex Engineering Works

Shape : Rectangle

Color : Blue

Condition : New

...more

Waste Paper Baling Press Machine

345,000 - 345,500 Per Nos

1 Nos (MOQ)

Paper Baling Press: The FABTEX manufacture Paper baling press is designed to bale up to 260kg, which can be compressed up to 1000mm. This important process in recycling resolves the problem of space and efficiency for most of the users. The volume reduction is approximately 10:1, this will mean reduced waste storage area and savings on transportation and labor costs. This machine mainly focuses on reliability, superior press force, and simple mechanism, maintenance free and safe functional working environment for the operator. Application: Aluminum cans, Cardboard, Paper, Pet Bottle, Coco Peat, Cotton pulp, Plant Fiber, Paper, Soft Plastic etc, Salient Features: · Wide feed Opening: for easy and efficient to feed large sized waste sheets. · High compaction ratio · Effective Operation: Inspection window for safety and dust reduction. · Electric Controlled for easy and simple operation. · High compaction ratio to meet the buyers demand. · Semi-Automatic bale ejection enables the work of operator easier. Technical Specification: Type FAB/PB/25 FAB/PB/30 FAB/CB/50 Capacity (t) 25 30 50 Hydraulic Pressure 150 180 200 Bale Size (mm) (L x W x H) 800 x 600 x 600 - 800 800 x 600 x 600 - 800 800 x 760 x 900 1100 x 760 x 900 Bale Weight (Kgs) Up to 100 Up to 160 Up to 200 Up to 260 Motor Power (HP) 7.5 10 15 Production (Bales/hr) Up to 4 Weight of the Machine (t) 2.0 2.3 2.5 3.25

Brand Name : Fabtex Engineering Works

Material : Steel

Finishing : Chrome Finish

Shape : Vertical

Color : Blue

Condition : New

Power : 5-30kw

Type : Hydraulic

Warranty : 12 months

Country of Origin : India

...more

Used Cloth Baling Press

3,510,000 - 3,510,500 Per Nos

Used Cloth Baling Press: We hold immense proficiency in manufacturing and supplying supreme quality Used Cloth Baling Press. This baler machine is specially designed to meet the demands of textile waste recycling industry. This has unique design and very simple to operate. One person can operate the complete cycle of each bale which saves huge cost on labor. In regards to the bale weight it can produce large capacity customized bale sizes.Features: Automatic Door: for easy operation and provide more work efficiency. Adjustable Bale Size: its easy to adjust the bale height by means of limit switches. Feeding: have provided weight less doors on the front which eases the material loading easier. Specification: MODEL UCB - 10 UCB - 20 UCB - 30 UCB - 40 UCB - 50 Baler Application Used Cloth, Quilt, Towel Bale Size (mm) Length 700 750 1100 1300 1500 Width 400 550 750 800 760 Height 700 800 350 900 900 Bale Weight (Kgs) Up to 70 Up to 200 Up to 500 Up to 750 Up to 1200 Bale Production (kgs/h) Up to 1500 Up to 1800 Up to 2500 Up to 3000 Up to 4000 Drain Channel Optional Conveyor Included Bale Ejection Automatic

...more

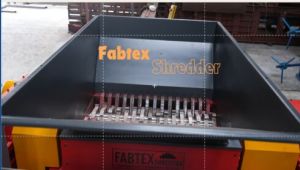

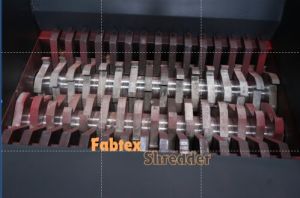

Tyre Shredder, 25 HP

5,150,000 - 5,150,500 Per Nos

The Fabtex make two-shaft shredder series features the latest in shredding technology with two high-powered electric motors engaging a rotor filled with exclusive cutting blades and knives.The newly designed cutting blade operates at extremely close tolerance which produce low wear cost features for new or existing shredder systems.Each shredder contains 24 blades for both the shaft that provide 6 cutting edges per insert. It undergoes at 13 processing steps to ensure the best performance and precision tolerance. This powerful combination provides years of worry free operation with minimal operating costs and maintenance…critical savings in a tire recycling operation. The Tire Shredder/Tyre shredder machine/Tire recycling machine is suitable for crushing the big solid material like television, washing machine, shell of refrigerator, big size pipe, pipe fittings, forklift splint, tyres, packing barrel, vehicle body, aluminum, copper and steel

...more

Twin Shaft Metal Shredder Machine

2,500,005 - 2,500,500 Per Nos

Fabtex Engineering Works: Advanced Twin Shaft Metal Shredding Solutions Introducing the high-performance Twin Shaft Metal Shredder Machine from Fabtex Engineering Works, Coimbatore, India. Our robust and efficient shredding solution revolutionizes metal waste processing for scrap yards, recycling facilities, and industrial metal recovery operations. Key Features: Powerful twin-shaft design for superior shredding capabilities Customizable shaft configurations for various metal types and sizes Hardened alloy steel blades for maximum durability and cutting efficiency Intelligent torque control system for optimal performance and safety Low-speed, high-torque operation for reduced noise and energy consumption Applications: Automotive scrap processing Industrial metal waste reduction White goods and appliance recycling Electronic waste pre-processing Foundry returns and metal swarf shredding Technical Specifications: Motors: 2 x [X] HP ([Y] kW) Shaft configuration: Twin counter-rotating shafts Blade material: High-strength, wear-resistant alloy steel Cutting chamber dimensions: [A] mm x [B] mm Throughput capacity: Up to [Z] tons per hour Power supply: 3-phase, 415V, 50Hz Benefits: Increased metal recycling efficiency and throughput Improved material liberation for better sorting and recovery Reduced transportation costs due to volume reduction Enhanced processing of tough and bulky metal scrap Lower operational and maintenance costs Our Twin Shaft Metal Shredder Machine effectively processes a wide range of materials, including: End-of-life vehicles and automotive parts Heavy steel scrap and structural steel Aluminum profiles and extrusions Copper and brass components Stainless steel and specialty alloys Fabtex Engineering Works' commitment to innovation ensures that our metal shredding machines meet the highest standards of performance, reliability, and efficiency. With years of expertise in recycling technology, we deliver customized solutions to meet your specific metal processing requirements. Why Choose Fabtex Engineering Works: Made in India: Supporting local manufacturing excellence Customization options to align with your recycling processes Comprehensive technical support and spare parts availability Proven track record in metal recycling solutions Competitive pricing for advanced shredding technology Optimize your scrap metal processing operations with Fabtex Engineering Works' Twin Shaft Metal Shredder Machine. Contact us today for expert consultation and a personalized quote.

...more

Twin Shaft E-Waste Shredder Machine

2,000,000 - 2,000,500 Per Nos

1 Nos (MOQ)

Our company is the prominent manufacturer, supplier, trader and exporter of the qualitative chain of Textile Machinery. Our offered products are well known for efficiency, high robustness, user-friendly controls and long functional life.

Application : E-Waste Shredder Machine

Capacity : 1000-1500 Kg/hr

Material : Iron

Shredding Material : Electronic waste

Shredding Capacity : 1000-1500 Kg/hr

Brand Name : Fabtex Engineering Works

Country of Origin : India

...more

triple action scrap baling press

575,500 - 575,600 Per Nos

1 Nos (MOQ)

Hydraulic Triple Action Scrap Baling Press: The ‘FABTEX’ make Scrap Baling Press machine is basically used in the processing of best quality Steel scrap material depending upon the requirement of the User. The steel block machine resolves the problem of space and efficiency for most of the users considering their production needs. Compact and small in size, these single action baling machines are highly suitable for lesser processing applications. These are not just easy to use but are capable of saving considerable costs for small traders by bundling their scrap. Furthermore, these machines are highly appreciated for their high tensile strength, longer functional life, reliability and low running cost.

Brand Name : Fabtex Engineering Works

Driven Type : Hydraulic

Color : Blue

Condition : New

Automatic Grade : Semi Automatic, Manual, Automatic

Power : 5-30kw

Warranty : 12 Months

Country of Origin : India

...more

Silk Waste Baling Press

1,255,009 - 1,255,510 Per Nos

Silk Waste Baling Press:We are instrumental in manufacturing Hydraulic Silk Waste Baling Press to our clients. It is constructed utilizing the latest technology and best quality factor inputs in accordance with the specified quality criteria. This press has the baling capacity of 6- 8 bales/hour. And consumes less power. Features: Electric Controlled for easy and simple operation Nine to twelve hoops or PP straps tying for a more secure and to maintain uniform bale shape Retainer Dogs optional depending upon the type and density of material used High Compact Ratio to meet the buyers demand Oil Cooler provided for maintaining viscosity and trouble free flow of Hydraulic Oil Hydraulic Door to make the work of operator easier Applications: Cotton Waste Cotton Coconut Fibre Synthetic Fibre Palm Fibre Silk Waste Technical Specifications: MODEL CFB - 10 CFB - 20 CFB - 30 Baler Application Cotton, Waste Cotton (Card Waste, Droppings etc.,), Acrylic Cotton, Waste Cloth, Coir fiber, Silk Waste, Raw Jute Bale weight (kgs) Up to 120 Up to 120 Up to 120 Bale Size (mm) Length 1220 1080 1080 Width 550 450 450 Height 700 550 550 Bale Production (kg/h) Up to 360 Up to 360 Up to 960 Material Feeding Conveyor Optional Bale Ejection Automatic

...more

Semi Electric Hydraulic Stacker

156,500 - 156,600 Per piece

We are into offering a quality assured assortment of Semi Electric Stacker. The Semi Electric Stacker we offer is recommended amongst the clients for its safe use. Offered products are known for their availability in committed time frame. Moreover, one can get these products at reasonable rates. Features: Lifting by fast manual pump (Without load) Manual Traction Descent by lever Nylon Rollers Parking brake Chromed Piston Adjustable forks 800 mm in length Oscillating double front rollers Technical Specifications: Model FMS 1000 FMS 1500 Load Capacity (Kg/Lbs) 1000/2200 1500/3300 Loading Centre (mm) 1600 1600 Fork Width (mm/inch) 140/5.5 140/5.5 Outside Width of Fork (mm) 680 680 Max. side of goods Outside (mm) 760 760 Front Wheel (mm) 90 78 Rear Wheel (mm) 180 180

Driven Type : Electric, Hydraulic

Color : Black, Blue, Brown

Condition : New

Automatic Grade : Semi Automatic

Power : 1-3kw

Application : Lifting Goods

...more

Scrap Metal Crusher

2,505,000 - 2,505,500 Per Piece

1 Nos (MOQ)

Advanced Scrap Metal Crushing Solutions Introducing the high-performance Scrap Metal Crushing Machine from Fabtex Engineering Works, Coimbatore, India. Our cutting-edge recycling equipment revolutionizes metal waste processing for scrap yards, foundries, and metal recycling facilities. Key Features: Powerful crushing mechanism designed for various metal types Adjustable crushing force for optimal material processing Wear-resistant alloy steel components for extended lifespan Advanced safety systems ensuring operator protection Energy-efficient design for reduced operational costs Applications: Automotive scrap processing Industrial metal waste reduction Foundry returns crushing Electronic waste pre-processing Metal recycling and recovery Technical Specifications: Motor: [X] HP ([Y] kW) Crushing mechanism: Hydraulic-powered compression system Crusher material: High-strength manganese steel Feed opening dimensions: [A] mm x [B] mm Throughput capacity: Up to [Z] tons per hour Power supply: 3-phase, 415V, 50Hz Benefits: Increased metal recycling efficiency Improved material density for transportation Enhanced metal separation and sorting capabilities Reduced processing time and labor costs Maximized scrap value through size reduction Our Scrap Metal Crushing Machine effectively processes a wide range of materials, including: Automotive parts and body panels Aluminum profiles and extrusions Steel drums and containers Copper wire and cable scrap Cast iron and steel components Fabtex Engineering Works' dedication to innovation ensures that our metal crushing machines meet the highest standards of performance and reliability. With years of expertise in recycling technology, we deliver customized solutions to meet your specific metal processing requirements. Why Choose Fabtex Engineering Works: Made in India: Supporting local manufacturing excellence Customization options to align with your recycling processes Comprehensive technical support and spare parts availability Proven track record in metal recycling solutions Competitive pricing for advanced crushing technology Optimize your scrap metal processing operations with Fabtex Engineering Works' Scrap Metal Crushing Machine. Contact us today for expert consultation and a personalized quote. Fabtex Engineering Works [Address] Coimbatore, Tamil Nadu, India Phone: [Phone number] Email: [Email address] Website: [Website URL] Keywords: scrap metal crusher, metal recycling equipment, industrial metal shredder, automotive scrap processor, foundry waste management, electronic waste recycling, metal recovery machine, Made in India, Coimbatore manufacturing, environmental sustainability, circular economy, resource recovery, waste reduction, green technology Embrace the future of metal recycling and contribute to a more sustainable industrial ecosystem with Fabtex Engineering Works' innovative crushing technology. Experience the power of Indian engineering in transforming metal waste into valuable resources. Certifications and Compliance: ISO 9001:2015 Quality Management System ISO 14001:2015 Environmental Management System CE Marked for European market compliance Adheres to national and international safety standards Join the metal recycling revolution with Fabtex Engineering Works' Scrap Metal Crushing Machine – where engineering excellence meets environmental responsibility in material processing and recovery.

Country of Origin : India

Brand Name : Fabtex Engineering Works

Warranty : 12 months

...more

Rubber Bale Cutting Machine

100,005 - 100,500 Per Nos

1 Nos (MOQ)

Raw Rubber Bale Cutter / Hydraulic Rubber Cutter / Rubber Sheet Cutting Machine1. Primary Uses This bale cutter is primarily designed for slicing natural rubber, synthetic rubber, and various plastic materials. It is especially effective when placed near a rubber mixer to segment smaller rubber pieces. The machine is equipped with a track system, facilitating easier rubber feeding. 2. Structure The main components of this bale cutter include a rubber knife, frame, cylinder, base, auxiliary table, hydraulic system, and electrical system. A lead plate is positioned on the base beneath the rubber knife to safeguard its edge. During operation, raw rubber is placed under the knife, and upon pressing the start button, the knife slices the rubber. Two limit switches on the frame regulate the reversal valve, directing the knife's movement and protecting the cylinder cover. 3. Features: Low noise operation Consistent temperature maintenance Automatic pressure maintenance and supplementation Robust construction, well-thought-out design, high efficiency, and user-friendly operation The cutting knife operates via a hydraulic system with a reciprocating motion

Country of Origin : India

Operation : Rubber Bale Cutting

Material : Steel

Brand : Fabtex Engineering Works

...more

Roofing Sheet Shredder Machine

2,000,005 - 2,000,500 Per Nos

Fabtex Engineering Works: Innovative Roofing Sheet Recycling Solutions Introducing the cutting-edge Roofing Sheet Shredder Machine from Fabtex Engineering Works, Coimbatore, India. Our advanced recycling solution revolutionizes the processing of metal and composite roofing materials for scrap yards, construction waste management facilities, and metal recycling plants. Key Features: Robust shredding mechanism designed for tough roofing materials Adjustable cutting parameters for various sheet types and thicknesses Hardened steel blades for long-lasting performance Integrated safety systems for operator protection Energy-efficient operation for reduced running costs Applications: Metal roofing sheet recycling Construction and demolition waste processing Scrap metal recovery Composite material breakdown Industrial waste management Technical Specifications: Motor: [X] HP ([Y] kW) Shredding mechanism: Heavy-duty rotary system Blade material: High-carbon, wear-resistant steel Feed opening dimensions: [A] mm x [B] mm Throughput capacity: Up to [Z] tons per hour Power supply: 3-phase, 415V, 50Hz Benefits: Increased recycling efficiency for roofing materials Improved material separation and recovery Reduced landfill waste from construction projects Enhanced value extraction from scrap roofing sheets Compliance with construction waste management regulations Our Roofing Sheet Shredder Machine effectively processes a wide range of materials, including: Corrugated metal sheets Standing seam panels Asphalt shingles Fiber cement roofing Composite roofing materials Fabtex Engineering Works' commitment to innovation ensures that our roofing sheet shredders meet the highest standards of performance and durability. With extensive experience in recycling technology, we provide tailored solutions to meet your specific material processing needs. Why Choose Fabtex Engineering Works: Made in India: Supporting local manufacturing excellence Customization options to suit your recycling requirements Comprehensive after-sales support and maintenance services Proven track record in industrial shredding solutions Competitive pricing for advanced recycling technology Optimize your roofing material recycling process with Fabtex Engineering Works' Roofing Sheet Shredder Machine. Contact us today for expert consultation and a customized quote.

...more

Reel Splitter Machine Paper Plastic

800,000 - 800,500 Per piece

1 piece (MOQ)

Paper Reel Splitter by Fabtex Engineering Works ### Advanced and Efficient Solutions for Paper Reel Splitting Looking for a high-performance solution for splitting paper reels with precision and ease? Fabtex Engineering Works introduces the Paper Reel Splitter, designed to handle paper reels of various sizes with exceptional accuracy and efficiency. Our splitter ensures optimal performance, enhancing productivity and supporting sustainable paper waste management practices. ### Why Choose Our Paper Reel Splitter? #### High Efficiency and Performance Fabtex Engineering Works' Paper Reel Splitter is equipped with powerful motors and precision-engineered blades, ensuring efficient and effective splitting of paper reels. The machine is designed to handle high volumes of material, providing consistent and reliable performance to enhance productivity in your operations. #### Durable and Robust Construction Built with high-quality materials and advanced manufacturing techniques, our paper reel splitter is designed to withstand the rigors of heavy-duty use. This durability ensures a long service life and minimal maintenance, saving you time and money in the long run. #### Precision and Accuracy Our paper reel splitter features precision-engineered blades and advanced control systems, ensuring accurate and clean cuts. This precision minimizes waste and maximizes the usability of split paper reels, improving overall efficiency. #### Safety and Compliance Safety is our top priority. Our paper reel splitter is designed with advanced safety features to protect operators and ensure safe processing of paper reels. The machine complies with all relevant safety and environmental regulations, ensuring that your operations meet industry standards. #### User-Friendly Design Our paper reel splitters feature intuitive controls and advanced safety mechanisms, making them easy to operate and maintain. Whether you're an experienced technician or new to industrial equipment, you'll find our machines user-friendly and efficient, ensuring smooth operation and safety for all users. ### Key Features - **Powerful Motors**: Ensure efficient splitting of paper reels. - **Precision Blades**: Engineered for accurate and clean cuts. - **Robust Construction**: Built to withstand heavy-duty use and ensure long-lasting durability. - **Safety Features**: Advanced mechanisms protect operators and ensure safe processing. - **User-Friendly Operation**: Intuitive controls for easy operation and maintenance. ### Applications Our Paper Reel Splitter is ideal for various applications, including: - Paper manufacturing plants - Printing industry - Recycling facilities - Packaging industry - Industrial waste management ### Contact Fabtex Engineering Works Ready to enhance your paper reel handling with the best Paper Reel Splitter on the market? Contact Fabtex Engineering Works today to learn more about our products and how they can benefit your operations. Invest in efficiency, precision, and durability with Fabtex Engineering Works – your trusted partner in advanced paper reel splitting solutions.

Brand Name : Fabtex Engineering Works

Color : Blue

Condition : New

Power Source : Electric

Warranty : 12 Months

Country of Origin : India

...more

Pp Raffia Lumps Shredder Machine

1,254,000 - 1,254,500 Per Nos

1 Nos (MOQ)

Our company is the prominent manufacturer, supplier, trader and exporter of the qualitative chain of Textile Machinery. Our offered products are well known for efficiency, high robustness, user-friendly controls and long functional life.

Application : Shredding

Capacity : 1000-1500 Kg/hr

Material : Iron

Shredding Material : Pp Raffia Lumps

Shredding Capacity : 1000-1500 Kg/hr

Shredding Machine Type : Single Shaft

Brand Name : Fabtex Engineering Works

Country of Origin : India

...more

Plastic Waste Shredder Machine

150,500 - 150,600 Per Nos

Plastic Waste Shredder Machine by Fabtex Engineering WorksEfficient and Reliable Solutions for Plastic Waste Management Are you searching for a high-performance shredder to tackle plastic waste? Fabtex Engineering Works presents the Plastic Waste Shredder Machine, engineered to efficiently handle various types of plastic waste with exceptional durability and performance. Our shredder ensures optimal processing and recycling of plastic materials, promoting sustainable waste management practices. Why Choose Our Plastic Waste Shredder Machine?High Efficiency and Performance Fabtex Engineering Works' Plastic Waste Shredder Machine is equipped with robust motors and precision-engineered blades, ensuring efficient and effective shredding of plastic waste. The machine is designed to handle high volumes of material, providing consistent and reliable performance to boost productivity in your operations. Durable and Robust Construction Built with high-quality materials and advanced manufacturing techniques, our shredding machine is designed to withstand the rigors of heavy-duty use. This durability ensures a long service life and minimal maintenance, saving you time and money in the long run. Eco-Friendly and Sustainable Our shredders are designed with sustainability in mind. By enabling thorough material recovery and recycling, our machines help reduce environmental impact. Choosing our shredders contributes to a cleaner and greener future, aiding in the responsible management and recycling of plastic waste. User-Friendly Design Our shredders feature intuitive controls and advanced safety mechanisms, making them easy to operate and maintain. Whether you're an experienced technician or new to industrial equipment, you'll find our machines user-friendly and efficient, ensuring smooth operation and safety for all users. Key Features Powerful Motors: High-torque motors for efficient shredding of various plastic materials. Precision Blades: Engineered for maximum cutting performance and longevity. Robust Construction: Built to withstand heavy-duty use and ensure long-lasting durability. Eco-Friendly Operation: Designed to minimize environmental impact through efficient material recovery. Safety Features: Advanced safety mechanisms to protect operators and ensure smooth operation. Applications Our Plastic Waste Shredder Machine is ideal for various applications, including: Recycling facilities Industrial waste management Manufacturing plants Packaging industry waste processing Environmental cleanup projects Municipal waste management Contact Fabtex Engineering Works Ready to enhance your plastic waste management with the best Plastic Waste Shredder Machine on the market? Contact Fabtex Engineering Works today to learn more about our products and how they can benefit your operations.

...more

plastic bags shredder machine

510,505 - 510,506 Per piece

Plastic Bags Shredder Machine by Fabtex Engineering Works**Product Overview:**The Plastic Bags Shredder Machine, manufactured by Fabtex Engineering Works, is an advanced shredding solution designed for efficiently processing plastic bags and a variety of other materials. Built with precision engineering and high-quality components, this machine is ideal for industries aiming to improve their waste management and recycling processes.**Key Features:**1. **Dual Shaft Shredding System:** - The machine features a robust dual shaft design, providing powerful and efficient shredding capabilities. This system ensures consistent and uniform particle size, facilitating further processing or recycling.2. **High Torque, Low Speed Operation:** - Incorporating high torque and low-speed technology, the shredder operates quietly and with reduced dust emission. This design minimizes wear and tear on the machine, extending its operational life.3. **Durable Construction:** - Made from high-grade materials, the shredder is built to withstand the demands of continuous industrial use. Its durable construction ensures long-term reliability with minimal maintenance requirements.4. **Automated Control System:** - Equipped with a sophisticated PLC-based control system, the shredder offers automated operation with minimal manual intervention. Safety features such as overload protection and automatic reverse function enhance usability and safety.5. **Versatile Shredding Capability:** - While optimized for shredding plastic bags, the machine is versatile enough to handle a wide range of materials including textiles, paper, cardboard, and other packaging materials. This versatility makes it a valuable asset for various industrial applications.6. **Energy Efficient:** - Designed to optimize energy consumption, the shredder provides high performance with low power usage, reducing operational costs and environmental impact.**Applications:**- **Recycling Centers:** Ideal for processing a variety of recyclable materials, improving the efficiency of recycling operations.- **Waste Management:** Suitable for shredding different types of waste, aiding in effective waste reduction and management efforts.- **Manufacturing:** Efficiently handles production waste such as plastic bags and other materials, contributing to cleaner and more organized production facilities.- **Retail and Distribution:** Helps in managing packaging waste from retail and distribution centers, promoting sustainable practices.**Technical Specifications:**- **Shredding Capacity:** Customizable to meet specific industrial needs- **Motor Power:** High torque motors designed for heavy-duty shredding- **Shredding Chamber Dimensions:** Adjustable to accommodate different material sizes- **Blade Material:** High-strength alloy steel for superior durability and performance- **Control System:** Automated PLC controls with integrated safety features**Customer Support and Service:**Fabtex Engineering Works provides extensive customer support, including installation, training, and maintenance services. This ensures that the Plastic Bags Shredder Machine operates at optimal performance, offering a reliable and efficient shredding solution.**Conclusion:**The Plastic Bags Shredder Machine by Fabtex Engineering Works is a versatile and efficient tool for shredding plastic bags and various other materials. Its robust design, advanced features, and broad application range make it an indispensable machine for industries focused on improving their waste management, recycling efforts, and overall operational efficiency.

...more

Pcb Circuit Board Crusher

850,000 - 850,500 Per Nos

1 Nos (MOQ)

Our company is the prominent manufacturer, supplier, trader and exporter of the qualitative chain of Textile Machinery. Our offered products are well known for efficiency, high robustness, user-friendly controls and long functional life.

Brand Name : Fabtex Engineering Works

Power : 5-30kw

Country of Origin : India

...more

Organic Waste Shredder

2,150,000 - 2,150,500 Per Nos

1 Nos (MOQ)

Organic Waste Shredder Machine by Fabtex Engineering WorksProduct Overview: The Organic Waste Shredder Machine, manufactured by Fabtex Engineering Works, is a powerful and efficient solution designed to manage and process organic waste. Ideal for industries and facilities focused on waste management, composting, and recycling, this machine ensures effective shredding of organic materials, promoting environmental sustainability and operational efficiency.Key Features:High-Efficiency Shredding:The machine is equipped with a robust shredding mechanism capable of processing a wide range of organic waste, including food scraps, garden waste, and agricultural residues. This ensures consistent particle size for effective composting and recycling.Dual Shaft Design:Featuring a dual shaft design, the shredder provides superior shredding capabilities, allowing it to handle large volumes of organic waste effortlessly. This design guarantees reliable performance even under heavy-duty conditions.Low-Speed, High-Torque Operation:Operating at low speed with high torque, the shredder minimizes noise and dust emissions, enhancing safety and comfort in the working environment. This also reduces wear and tear on the machine, extending its lifespan.Durable Construction:Constructed from high-quality materials, the organic waste shredder is built to withstand continuous industrial use. Its sturdy construction ensures long-term reliability and minimal maintenance requirements.Advanced Control System:The shredder is equipped with an advanced PLC-based control system, offering automated operation with minimal human intervention. Safety features such as overload protection and automatic reverse enhance usability and safety.Applications:Composting Facilities: Ideal for shredding organic waste into smaller, manageable pieces, facilitating faster and more efficient composting processes.Waste Management: Suitable for processing various types of organic waste, aiding in effective waste reduction and management efforts.Agricultural Sector: Efficiently handles agricultural residues, promoting sustainable agricultural practices and waste recycling.Food Processing Industries: Helps in managing food waste, contributing to cleaner and more organized production facilities.Municipal Waste Management: Enhances the processing of organic municipal waste, supporting community recycling and waste reduction programs.Technical Specifications:Shredding Capacity: Customizable to meet specific industrial needsMotor Power: High-torque motors designed for heavy-duty shreddingShredding Chamber Dimensions: Adjustable to accommodate different material sizesBlade Material: High-strength alloy steel for superior durability and performanceCustomer Support and Service: Fabtex Engineering Works provides comprehensive customer support, including installation, training, and maintenance services. This ensures that the Organic Waste Shredder Machine operates at optimal performance, providing a reliable and efficient shredding solution.Conclusion: The Organic Waste Shredder Machine by Fabtex Engineering Works is a versatile and efficient tool for shredding various types of organic waste. Its robust design, advanced features, and wide range of applications make it an indispensable machine for industries focused on waste management, composting, and recycling, enhancing their overall operational efficiency and sustainability.

Usage/Application : waste management

Shredding Material : Waste

Country of Origin : India

...more

Movable Dock Ramp

4,355,000 - 43,550,500 Per Nos

A movable dock ramp, also known as a mobile loading ramp or portable loading dock, is a versatile and essential piece of equipment designed to facilitate the loading and unloading of containers and trucks. This ramp is specifically engineered for flexibility and ease of use, making it ideal for warehouses, distribution centers, and industrial facilities. Key Features: Mobility: Equipped with durable wheels or casters, allowing easy movement and positioning around the loading area. Adjustable Height: Features a hydraulic or mechanical system to adjust the height, ensuring compatibility with various truck and container bed heights. Non-Slip Surface: The ramp surface is designed with anti-slip materials or textured patterns to provide secure traction for forklifts and personnel. Heavy-Duty Construction: Built from high-strength steel or aluminum, ensuring it can support substantial weights typically encountered in loading and unloading operations. Safety Features: Includes safety rails or curbs to prevent equipment from falling off the sides, and often comes with locking mechanisms to secure the ramp in place during use. Load Capacity: Designed to handle significant weight loads, often ranging from several tons to accommodate various industrial needs. Easy Setup and Breakdown: Engineered for quick assembly and disassembly, enabling efficient setup and storage when not in use. Applications: Loading and unloading shipping containers. Bridging the gap between dock height and truck bed height. Facilitating forklift and manual pallet truck operations in loading docks. Temporary loading solutions at construction sites or remote locations. Overall, a movable dock ramp enhances operational efficiency, safety, and flexibility in material handling tasks, making it a crucial asset for industries that require regular and efficient loading and unloading operations.

...more

MCC Waste Shredder

255,000 - 255,500 Per Nos

1 Nos (MOQ)

Our company is the prominent manufacturer, supplier, trader and exporter of the qualitative chain of Textile Machinery. Our offered products are well known for efficiency, high robustness, user-friendly controls and long functional life.

Brand Name : Fabtex Engineering Works

Shredding Material : MCC Waste

Usage/Application : Shredding

Country of Origin : India

Model Name : MCC Waste Shredder

...more

Manual Tie Horizontal Balers

1,350,005 - 1,350,500 Per Nos

1 Nos (MOQ)

Manual Tie Horizontal Balers by Fabtex Engineering Works**Introduction:**Fabtex Engineering Works introduces the Manual Tie Horizontal Balers, a robust and reliable solution for compacting various recyclable materials. This machine is ideal for recycling centers, waste management facilities, and manufacturing units, offering an efficient and cost-effective way to manage waste.**Key Features:**1. **Manual Tie System:** - The manual tie system allows for precise control over the baling process. Operators can easily secure bales with ties, ensuring uniformity and stability of the compacted materials.2. **Horizontal Design:** - The horizontal configuration of the baler facilitates easy loading and handling of materials. This design is particularly suited for bulky items, maximizing space efficiency and operational productivity.3. **High Compression Force:** - Equipped with a powerful hydraulic system, the baler delivers significant compressive force, producing dense and uniform bales. This ensures optimal space utilization during storage and transportation.4. **Sturdy Construction:** - Built with high-quality materials, the baling press is designed for durability and longevity. Its robust construction ensures reliable performance even in demanding industrial environments.5. **User-Friendly Operation:** - The machine features an intuitive control panel, allowing operators to easily manage and monitor the baling process. Adjustable settings provide precise control over bale size and density.6. **Efficient Bale Ejection:** - The efficient bale ejection system facilitates easy removal of compacted bales, minimizing downtime and enhancing productivity.7. **Safety Features:** - Multiple safety mechanisms, including emergency stop buttons, safety interlocks, and protective guards, ensure a safe working environment for operators.8. **Energy Efficiency:** - Designed with energy-saving components, the machine minimizes power consumption while maintaining high performance, reducing operational costs and supporting sustainable practices.**Technical Specifications:**- **Compression Force:** High-powered hydraulic system- **Motor Power:** Efficient motors for continuous operation- **Control System:** Advanced, user-friendly control panel- **Construction:** Heavy-duty steel frame- **Bale Size:** Adjustable to meet different material requirements- **Tie System:** Manual for precise and secure bale tying**Applications:**1. **Recycling Centers:** - Efficiently compacts recyclable materials like cardboard, paper, plastics, and textiles, making them easier to store, transport, and process.2. **Waste Management Facilities:** - Helps manage waste more effectively by reducing the volume of waste materials, enhancing storage and transportation efficiency.3. **Manufacturing Units:** - Ideal for managing production waste, ensuring efficient handling and disposal of offcuts and scrap materials.**Benefits:**1. **Enhanced Productivity:** - The manual tie system allows for flexible and precise control over the baling process, increasing overall productivity in waste management and recycling operations.2. **Cost Efficiency:** - By reducing manual labor and optimizing material handling, the machine lowers operational costs. Its durable construction and energy-efficient design further contribute to long-term cost savings.3. **Environmental Sustainability:** - Facilitates recycling efforts by compacting recyclable materials, reducing landfill waste, and supporting sustainable waste management practices.

Brand Name : Fabtex Engineering Works

Material : Iron

Driven Type : Electric, Hydraulic

Color : Blue

Condition : New

...more

LDPE Milk Pouches Shredding Machine

150,000 - 150,500 Per Nos

LDPE Milk Pouches Shredding Machine by Fabtex Engineering WorksInnovative Solutions for Efficient LDPE Milk Pouch Waste Management Are you in need of a reliable and efficient shredder specifically designed for LDPE milk pouches? Fabtex Engineering Works offers top-of-the-line shredding machines tailored to handle LDPE milk pouch waste with outstanding performance and durability. Our shredders are perfect for various applications, ensuring optimal processing and recycling of LDPE milk pouches. Why Choose Our LDPE Milk Pouches Shredding Machine?High Efficiency and Performance Fabtex Engineering Works' LDPE Milk Pouches Shredding Machine is equipped with powerful motors and precision-engineered blades, ensuring efficient and effective shredding of LDPE milk pouches. The machine is designed to handle high volumes of material, providing consistent and reliable performance. Eco-Friendly and Sustainable Our shredders are designed with sustainability in mind. By enabling thorough material recovery and recycling, our machines help reduce environmental impact. Choosing our shredders contributes to a cleaner and greener future, aiding in the responsible management and recycling of LDPE milk pouch waste. Robust and Durable Construction Built with high-quality materials and advanced manufacturing techniques, our shredders are designed to withstand the rigors of heavy-duty use. This durability ensures a long service life and minimal maintenance, saving you time and money in the long run. User-Friendly Design Our shredders feature intuitive controls and advanced safety mechanisms, making them easy to operate and maintain. Whether you're an experienced technician or new to recycling equipment, you'll find our machines user-friendly and efficient. Key Features Powerful Motors: High-torque motors for efficient shredding of LDPE milk pouches. Precision Blades: Engineered for maximum cutting performance and longevity. Robust Construction: Built to withstand heavy-duty use and ensure long-lasting durability. Eco-Friendly Operation: Designed to minimize environmental impact through efficient material recovery. Safety Features: Advanced safety mechanisms to protect operators and ensure smooth operation. Applications Our LDPE Milk Pouches Shredding Machine is ideal for various applications, including: Recycling facilities Dairy industry waste management Industrial waste processing Packaging industry waste processing Environmental cleanup projects Contact Fabtex Engineering Works Ready to enhance your LDPE milk pouch waste management with the best LDPE Milk Pouches Shredding Machine on the market? Contact Fabtex Engineering Works today to learn more about our products and how they can benefit your operations. Invest in efficiency, durability, and sustainability with Fabtex Engineering Works – your trusted partner in advanced LDPE milk pouch shredding solutions.

...more

Industrial Wood Shredder

2,160,000 - 2,160,500 Per Nos

### Industrial Wood Shredder by Fabtex Engineering Works**Product Overview:**The Industrial Wood Shredder, crafted by Fabtex Engineering Works, is a versatile and robust machine designed for efficiently shredding wood and a variety of other materials. Engineered for heavy-duty performance and durability, this shredder is ideal for industries seeking to enhance their waste management and recycling processes.**Key Features:**1. **Powerful Shredding Mechanism:** - The machine features a high-torque, dual-shaft design, enabling it to handle large volumes of wood and other materials with ease. This ensures consistent shredding performance and uniform particle size.2. **High Torque, Low Speed Operation:** - Utilizing a high-torque, low-speed system, the shredder operates quietly and with minimal dust emission. This not only enhances safety but also reduces wear and tear, extending the machine's lifespan.3. **Sturdy Construction:** - Built with high-quality materials, the shredder is designed to withstand continuous industrial use. Its durable construction ensures long-term reliability and minimal maintenance requirements.4. **Automated Control System:** - Equipped with an advanced PLC-based control system, the shredder offers automated operation with minimal human intervention. Features such as overload protection and automatic reverse enhance safety and ease of use.5. **Multi-Material Capability:** - Although optimized for shredding wood, this versatile machine can also handle a range of other materials, including plastics, metals, textiles, and paper. This flexibility makes it a valuable asset for various industrial applications.6. **Energy Efficient:** - Designed for energy efficiency, the shredder delivers high performance with low power consumption, helping to reduce operational costs and environmental impact.**Applications:**- **Woodworking Industry:** Ideal for shredding wood scraps, off-cuts, and other wood waste, promoting efficient waste management and recycling.- **Recycling Centers:** Enhances the processing of various recyclable materials, improving overall recycling efficiency.- **Manufacturing:** Efficiently handles production waste such as wood, plastic, and metal, contributing to cleaner and more organized production facilities.- **Construction Sites:** Shreds construction debris and materials, facilitating sustainable construction practices.- **Waste Management:** Suitable for shredding different types of waste, aiding in effective waste reduction and management efforts.**Technical Specifications:**- **Shredding Capacity:** Customizable to meet specific industrial requirements- **Motor Power:** High torque motors designed for heavy-duty shredding- **Shredding Chamber Dimensions:** Adjustable to accommodate different material sizes- **Blade Material:** High-strength alloy steel for superior durability and performance- **Control System:** Automated PLC controls with integrated safety features**Customer Support and Service:**Fabtex Engineering Works offers extensive customer support, including installation, training, and maintenance services. This ensures that the Industrial Wood Shredder operates at optimal performance, providing a reliable and efficient shredding solution.**Conclusion:**The Industrial Wood Shredder by Fabtex Engineering Works is a versatile and efficient tool for shredding wood and various other materials. Its robust design, advanced features, and broad application range make it an indispensable machine for industries focused on improving their waste management, recycling efforts, and overall operational efficiency.

...more

Industrial Plastic Waste Shredder

125,009 - 125,509 Per Piece

1 Nos (MOQ)

Plastic Shredding Machine Our company is the prominent manufacturer, supplier, trader and exporter of the qualitative chain of Textile Machinery. Our offered products are well known for efficiency, high robustness, user-friendly controls and long functional life.

Application : Shredding

Capacity : 1000-1500 Kg/hr

Material : Iron

Shredding Material : Waste

Shredding Capacity : 1000-1500 Kg/hr

Brand Name : Fabtex Engineering Works

Country of Origin : India

...more

e-waste

1,275,000 - 1,275,100 Per Nos

The Fabtex manufacturer E-Waste Shredders and Granulators are tailor-made to suit specific customer requirements of recycling different types of e-wastes. This machine developed and designed Shredders and Granulators, especially suitable for recycling of e-waste at affordable price and easy recovery of economical products during recycling process. These powerful shredders Hard Drives, Network Servers, Printers, Copy Machines, Computers, Motherboards, and much more with ease. With a large range of e-waste shredders, ranging in size from 8.5” x 16” to 40” x 72” has an electronic waste shredder to meet your need. Our low-speed, double shaft shredders are particularly suited for this process. The low speed ensures that the electronic waste is carefully shredded with low emissions. The shredded material is ideally suited for e-scrap recycling machines and subsequently for cutting facilities where precious metals are separated from their impurities. Applications: Light electronic scrap, laptop, hard drives, etc.,

...moreBe first to Rate

Rate This