Finned Tube Heat Exchanger

Get Price Quote

We offer Finned Tube Heat Exchangers, which are designed as per the international standards and requirements of the clients. These Finned Tube Heat Exchangers can be employed for cooling or heating of air or other gases which flow in a duct or cooling of water and other liquids using air. Also, these Finned Tube Heat Exchangers are provided with Aluminium extruded finned tubes. These Finned Tube Heat Exchangers are manufactured with copper, aluminum, stainless steel, admiralty brass, cupro-nickel or carbon steel. Apart from this, these strongly constructed Finned Tube Heat Exchangers are widely used in different applications like air laden with abrasive particles, corrosive fluids and air heating with steam and designed for special custom-built applications. Highlights Rugged construction Corrosion resistant Available with customization High durability Low maintenance cost Trouble-free operation Industrial Applications Food processing Textile SugarDrier Manufacturing Cement plants

Finned Tube Heat Exchanger

Get Price Quote

JC Finned Tube Heat Exchangers are specially designed and developed by our team and for your applications using Europe Technology ie., with Spiral Wound Finned Tubes and also the heat exchangers are extremely efficient in recovery of heat without an supplementary segment change. The types of FTHE are, Stainless Steel, Copper, Brazed, Finned Coil, Aluminium.

Best Deals from Finned Tube Heat Exchanger

Finned Tube Heat Exchanger

Get Price Quote

Dear sirmadam, greetings for the day… we jc equipments pvt ltd take pleasure to introduce ourselves as one of the leading designers, manufacturers & exporting of all kind of cooling towers,heat exchangers pressure vessels columns, storage tanks, air cooled condensers, etc.. In india. Jc equipments pvt ltd started in the year of 1989. We have wide knowledge in this field and we have regular customers throughout the world. We are authorized manufacturers of asme and we have “u, s & r” stamp certification also. We are corporate member of cti, usa. We are a world class manufacturers and we never compromise in quality. We assure our product will be best quality and competitive price. Herewith we have enclosed the product profile for your kind reference. Kindly refer the attachment. Looking forward your valuable enquiry for us to quote our best and competitive offers, with assuring you of our best quality and prompt service at all times.

Finned Tube Heat Exchanger

Get Price Quote

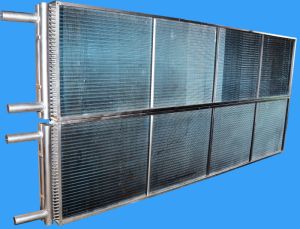

We are offering Plate-fin heat exchanger is one of the most efficient compact heat exchanger. The gaps between constitute a fluid layer. A core is made of a great number of layers. The exchanger can be made of one or more cores. The number of plate and fin layers, the size of the plates and fin, the height of the fin and the type of fin are engineered for optimum performance. The core is assembled (stacked) and typically held together by tack welding a weld rod to the top and bottom layer of the core. The stacked core is then placed within a fixture that exerts force on the individual pieces to keep them in contact. The part is then vacuum brazed in an environmentally-controlled room to ensure high quality and reliability. After brazing the core is typically heat treated or aged in order to increase its strength. Manifold ducting and mounting brackets are then welded in place as required, and any required paint or coating can be added.

finned tube heat exchangers

Get Price Quote

FTH is a pressure vessel which cools a circulating fluid within finned tubes by forcing ambient air over the exterior of the tubes. It does not required water. Major Elements of Finnned Tube Heat Exchanger: Tubes, Fins and Fan (Actuating Device for Heat Transfer) Finned Tube Material: The material selection is made as per Process Application, And Cost of Heat Exchangers We use following materials for Constructions: Carbon Steel, Stainless Steel, Admiralty brass, Copper and Exotic Alloys, Seamless, and Welded Stainless Steels, Seamless, and Welded, 2205 Duplex, Copper Nickel, Admiralty Brass, Titanium. Fin Materials: We use mostly Aluminum Fins and Copper Wire Fins for Specific Applications. Galvanized Iron Fins – For Low cost Projects. Types of JC Finned Tube Heat Exchanger: Stainless Steel Finned Tube Heat Exchangers Copper Finned Tube Heat Exchangers Finned Coil Heat Exchangers Brazed Fin Heat Exchanger Aluminium Finned Heat Exchanger International Codes & Specification: ASME Section I & VIII Division 1 TEMA API 660 API 661 National Board

Finned Tube Heat Exchanger

10,000 - 300,000 Per Piece

1 Piece (MOQ)

finned tube heat exchangers

Get Price Quote

Finned Tube heat exchangers are most commonly used for forced air heating and cooling systems, such as with indoor and outdoor wood furnaces, boilers, and stoves.These units rely on air-to-air heat exchange through evaporator units similar to those used for air conditioners. Finned Tube can also be suitable for liquid cooling applications.

Finned Tube Heat Exchanger

Get Price Quote

Finned Tube Heat Exchangers consist of a shell & finned tubes assembly. Fins are used to increase the effective surface area of heat exchanger tubing. Finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside; as in heat transfer from a liquid to a gas, vapor to a gas, such as steam to air heat exchanger, thermic fluid to air heat exchanger. When an extended surface is needed on only one fluid side (such as in a gas to liquid exchanger) or when the operating pressure needs to be contained on one fluid side, a finned tube heat exchanger may be selected. Applications of finned tube heat exchangers include Steam air heater / steam radiator, Thermic fluid air heater / thermic fluid radiator, Hot water air heater / hot water radiator, Air heater for fluid bed dryers, Air heater for spray dryers, Air heater for flash dryers and Air heater for dryers.

finned tube heat exchangers

Get Price Quote

FTH is a pressure vessel which cools a circulating fluid within finned tubes by forcing ambient air over the exterior of the tubes. It does not required water. Major Elements of Finnned Tube Heat Exchanger: Tubes, Fins and Fan (Actuating Device for Heat Transfer) Finned Tube Material: The material selection is made as per Process Application, And Cost of Heat Exchangers We use following materials for Constructions: Carbon Steel, Stainless Steel, Admiralty brass, Copper and Exotic Alloys, Seamless, and Welded Stainless Steels, Seamless, and Welded, 2205 Duplex, Copper Nickel, Admiralty Brass, Titanium.

Finned Tube Heat Exchanger

Get Price Quote

The surface area of the heat exchanger tubing is increased by our extraordinarily designed fins and in turn this increases maximum heat transfer.They are durable, reliable and require less maintenance. Steam or thermic fluid is utilized as hot medium in these exchangers.

finned tube heat exchangers

Get Price Quote

Finned Tube Heat Exchangers is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids. It is often categorized as a compact heat exchanger to emphasise its relatively high heat transfer surface area to volume ratio. The plate-fin heat exchanger is widely used in many industries, including the aerospace industry for its compact size and lightweight properties, as well as in cryogenics where its ability to facilitate heat transfer with small temperature differences is utilized. A high degree of flexibility is present in plate-fin heat exchanger design as they can operate with any combination of gas, liquid, and two-phase fluids. Heat transfer between multiple process streams is also accommodated, The main four type of fins are: plain, which refer to simple straight-finned triangular or rectangular designs; herringbone, where the fins are placed sideways to provide a zig-zag path; and serrated and perforated which refer to cuts and perforations in the fins to augment flow distribution and improve heat transfer. Specifications : Originally conceived by an Italian mechanic, Paolo Fruncillo. A plate-fin heat exchanger is made of layers of corrugated sheets separated by flat metal plates, typically aluminium, to create a series of finned chambers. Separate hot and cold fluid streams flow through alternating layers of the heat exchanger and are enclosed at the edges by side bars. Heat is transferred from one stream through the fin interface to the separator plate and through the next set of fins into the adjacent fluid. The fins also serve to increase the structural integrity of the heat exchanger and allow it to withstand high pressures while providing an extended surface area for heat transfer. Applications : The cost of Fin heat exchangers is generally higher than conventional heat exchangers due to a higher level of detail required during manufacture. However, these costs can often be outweighed by the cost saving produced by the added heat transfer. Fin heat exchangers are generally applied in industries where the fluids have little chances of fouling. The delicate design as well as the thin channels in the fin heat exchanger make cleaning difficult or impossible. Advantages : High heat transfer efficiency especially in gas treatment Larger heat transfer area Approximately 5 times lighter in weight than that of shell and tube heat exchanger. Able to withstand high pressure

Finned Tube Heat Exchanger

Get Price Quote

wooden cooling towers, Cooling Tower Pvc V Bar, Cooling Tower Branch Pipe

finned tube heat exchangers

Get Price Quote

dry cooler, evaporator coil, humidification plants, Marine Heat Exchanger

Finned Tube Heat Exchanger

Get Price Quote

Flue Gas Air Pre Heater, Air Cooled Heat Exchangers