Economy Punch Cum Splitter

Get Price Quote

We are offering economy punch cum splitter. economy version of punch cum splitter without storage facility and tray.

Hammer Mill

600,000 - 700,000 Per piece

1 Bag (MOQ)

Product includes Hammer mill, Screw conveyor, Shifter & Blender.

Best Deals from Grinding Mill

Hammer Mill

30,000 Per Piece

With the assistance of our skilled and experienced workforce, we have been able to Exporter, Importe..With the assistance of our skilled and experienced workforce, we have been able to Exporter, Importe....

Coconut Disintegrator

55,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Block Splitter

Get Price Quote

Hydril Equipments - This Machine is a hydraulically operated shearing machine used to shear concrete blocks, which gives the sheared face a granite like surface. Hydraulic Block Splitter Specification: Semi Automatic Operation. Blade : 600 mm long. Power : 7.5 HP. Shearing Height : 40 to 230 mm. Cutout force : 20,000 kg Hydraulic pressure : 115 kg / cm2 Fully Automatic Operation. Blade : 600 mm long. Power : 20 HP. Shearing Height : 60 to 230 mm. Cutout force : 20,000 kg Hydraulic pressure : 115 kg / cm2

Ink Grinding Mill

Get Price Quote

wood splitter

Get Price Quote

Medium Speed Trapezium Grinder

Get Price Quote

MTM Medium Speed Trapezium grinder is a kind of leading-world-level industrial milling machinery. It is designed by our own engineers and technical workers, basing on industrial mill research of many years and adopting world-leading-powder processing technology. Now a number of customers are fond of it for its incomparable features. Pretreatment: Using the hydraulic hammer to crush the big stone into smaller one, and arrange the worker to cut through the long reinforcement to prevent damaging the belt conveyor. Technical improvement based on environmental protection concept.. High efficient and energy saving centrifugal draft fan. High density and precision impeller device. Quick adjustment and maintenance

Planetary Ball Mill

Get Price Quote

PSG Planetary ball mill is ideally suitable for industries and educational institutions, wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding. The extreme high centrifugal forces of the planetary ball mills results in very high pulverization energy and hence the time required for grinding is comparatively less.Nano particle dimensions and other physical properties can be modified by adjusting the process parameters such as grinding medium, ball ratio, ball material, motor rpm, etc., Thus, the machine would greatly help the researchers and students to learn the nano particle synthesis in bulk using top down approach. Customized set up can also be supplied.

Mini Skid Steer Log Splitter

Get Price Quote

Hammer Mill

Get Price Quote

Disintegrator

Get Price Quote

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Hammer Mill

Get Price Quote

The usage of Hammer Mill is varied and widespread. At our Mill, these Hammer Mills are used mainly for the purpose of grinding. The underlying principal of a Hammer Mill is quite simple. A vertical and horizontal rotating steel shaft in the form of a drum is used and on which a hammer is mounted. Inside, the hammers contain a central rotor which is spun into high speed thereby shredding the particles fed into it, in required shapes or sizes. The electricity used can range from 1.5-3.7MW depending on the requirement from the end user.

Ball Mill

120,000 Per Piece

De-Airing Pug Mill

Get Price Quote

The De-Airing Pug Mill that we Manufacture, Export, and Supply is highly acclaimed by the clients due to its excellent quality. Manufactured from quality components, this De-Airing Pug Mill ensures exceptional reliability to the users. This De-Airing Pug Mill is user friendly and due to that, it is highly admired by the clients.

wood log splitter

Get Price Quote

Hydraulic wood splitter

Get Price Quote

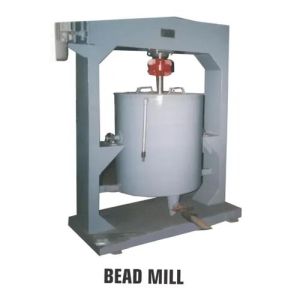

Stainless Steel Bead Mill

500,000 Per Piece

2 Piece (MOQ)

Hammer Mills

Get Price Quote

Some pellet plants start their process by putting large pieces of wood through a chipping machine for processing. These are only necessary for mills that accept this non-uniform feed stock. There are many different configurations to pellet manufacturing plants depending on their raw material source. While they all don't have chippers, almost all of them have a hammer mill at the beginning of their milling process. These machines take sawdust and wood chips and break them down into a consistent smaller size, making drying and pressing through the pellet die quick and consistent.

wood splitter

Get Price Quote