GASKETED PLATE & FRAME HEAT EXCHANGER

Get Price Quote

The Gasketed Plate & Frame Type Heat Exchanger that are made by us are premium in quality which is made using the best variety of raw materials. This plate heat exchanger is corrosion resistant and can easily be installed anywhere. Plate and frame heat exchangers comes in a compact design that assures greater efficiency, low hold-up volume, expandability and flexibility, easy maintenance, and close temperature approaches. Typical Applications HVAC Refrigeration Food, Beverage & Dairy Process Systems Sanitary Plate Heat Exchangers

Heat Exchanger

Get Price Quote

The primary function of a Heat Exchanger is to efficiently transfer heat from one medium to another. We are the Manufacturer and Supplier of excellent quality Heat Exchanger that is precisely manufactured by using the best quality raw materials. These Heat Exchangers are designed by using the latest metal forming and cutting equipments that produces the best exchangers. Our Heat Exchangers are fabricated from different materials like carbon steel, aluminum bronze, stainless steel, naval brass, nickel and cupronickel. Features : Lower vibration riskImproved two-phase flow distributionReduced shellside foulingLower shellside pressure drop Uses : Separation of air gasesHydrocarbon processingNatural gas liquefactionIndustrial gas liquefaction

Best Deals from Heat Exchangers

Tube Bundles

Get Price Quote

We can make timely delivery of bulk as well as retail orders courtesy a wide vendor, distributor and logistic service provider base. One of the leading companies based in Tamil Nadu(India), we are a known for the exceptional assortment of products.

Wire Wound Heat Exchanger

Get Price Quote

PVC Cooling Tower Fills

150 Per Piece

100 Piece (MOQ)

Air Blast Oil Cooler

Get Price Quote

Hi tech offers Air Blast Oil Coolers or Air Blast Coolers for heat dissipation ranging from 1500 kcalhr (1.7 kW) to 90000 kcalhr (105 kW). These air blast oil coolers are typically used in places where raw water availability for cooling purposes is scarce. Typical applications are for hydraulic oil, lube oil and transformer oil cooling. Teccon Air Blast Coolers effectively overcome heating problems and provides optimum heat transfer depending on the application. These coolers are supplied as O.E. fitments to leading machinery manufacturers.

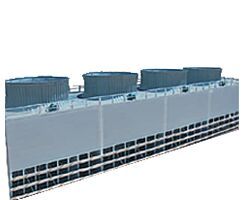

Forced Draft Cooling Towers

Get Price Quote

We are offering forced draft cooling towers, gireesh are an accredited manufacturer and supplier of high quality forced draught cooling towers that are widely used in various industries. These cooling towers are manufactured using quality-approved factor inputs, which we source from the authentic vendors of the industry. Our offered range is available in various specifications in order to meet the varied needs of the clients. features: • rigid construction • corrosion resistance • longer service life features • forced draught fan handles cold and dry air with less specific volume, and hence, air flow quantity is lesser for a given duty than induced draught • also, we use world renowned high efficiency fills, which has lesser static resistance than any other type of fill • finally, the velocity pressure which gets wasted into the atmosphere in induced draught is utilized effectively in the forced draught system that we offer, contributing to savings in power • the exit air velocity is less in a forced draught cooling tower, therefore, the carry over loss gets minimized • coupled with this, very high efficiency drift eliminators reduce the total drift loss to max. 0.05% compared with 0.2-0.3% for other systems • this also eliminates the drift nuisance as well as algae formation.

Coil Type Heat Exchanger

Get Price Quote

Coil Type Heat Exchanger is nothing but Copper tubes are artificial to special requirements as to dimensional tolerances, finish and tempers for use in condensers and heat exchangers. These copper heat exchanger tubes are normally supplied in straight length in annealed & half hard temper. The copper tubes shaped by are metal industries not only have the stiff tolerances but also have the most dependable dimensions throughout the tube length. The tube surface is clean both inside and outside with no caustic stains. The copper tubes produced by are metal industries are suitable to transfer heat in a wide variety of operating conditions and to refuse to accept decay for the longest period of time possible under the harshest operating circumstances.Coil type exchangers are more efficient than shell and tube exchangers for low flow rates. Due to their simple construction they are low in price and easy to clean on the shell side. Their thermal efficiency approximates that of a true countercurrent flow type exchanger. Condenserors are used for condensation of vapours and cooling of liquids. Condensers are made by fusing number of parallel coils in a glass shell. Coils are made in different diameters using tubes of different bores. Specifications : Copper tubes are important because motors and motor-driven systems account for 43%-46% of all global electricity consumption and 69% of all electricity used by industry. Increasing the mass and cross section of copper in a coil increases the electrical energy efficiency of the motor. Copper motor rotors, a new technology designed for motor applications where energy savings are prime design objectives, are enabling general-purpose induction motors to meet and exceed National Electrical Manufacturers Association (NEMA) premium efficiency standards. Applications : The major applications of copper are in electrical wires (60%), roofing and plumbing (20%) and industrial machinery (15%). Copper is mostly used as a metal, but when a higher hardness is required it is combined with other elements to make an alloy (5% of total use) such as brass and bronze. A small part of copper supply is used in production of compounds for nutritional supplements and fungicides in agriculture. Machining of copper is possible, although it is usually necessary to use an alloy for intricate parts to get good machinability characteristics. Advantages : The electrical properties of copper are exploited in copper wires and devices such as electromagnets. Integrated circuits and printed circuit boards increasingly feature copper in place of aluminium because of its superior electrical conductivity (see Copper interconnect for main article) Heat sinks and heat exchangers use copper as a result of its superior heat dissipation capacity to aluminium. Vacuum tubes, cathode ray tubes. The magnetrons in microwave ovens use copper, as do wave guides for microwave radiation. Copper’s greater conductivity versus other metallic materials enhances the electrical energy efficiency of motors.

Plate Heat Exchangers

Get Price Quote

Plate Heat Exchangers is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This is a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible.

aluminum heat exchangers

Get Price Quote

Aluminum Heat Exchangers high thermal conductivity allows heat to pass through it quickly. Other desireable properties of copper in heat exchangers

adiabatic cooling tower

Get Price Quote

Adiabatic Cooling Tower unit built thus on scale back the body of water air temperature to the coil. This provides the shoppers with important reductions within the price|cost of capital opportunity cost of the cooler further as reductions within the cost of power consumption. associate electronic temperature controller is employed to regulate the fluid (process water) temperature inside rigorous tolerances. This temperature controller pulses the sprays of water onto the cooling pads to relinquish solely the minimum of adiabatic cooling of the body of water air needed for any given load and close condition.All style options area unit in to produce a protracted product life.

Air Aftercoolers

Get Price Quote

We are successful suppliers of various industrial coolers. Realizing the need to increase device performance, we have introduced the After Coolers. They are an important component of air compressors. Our after cooler cools discharged air, decreases air moisture level and protects the equipment from heat. Along with protection, it plays a vital part in increasing system capacity and performance.Along with standard models, we also customize after coolers as per the specifications and requirements given by the customers. These coolers manufactured by us successfully reduce temperature of air, down to within 8° C. We offer our range at most affordable prices. Features: Long service life Easy to transport Highly efficient Excellent quality Less maintenance

Round Shape Cooling Tower

Get Price Quote

Round shape cooling tower are called as Bottle shape cooling towers and induced draft counter flow cooling towers. Round shape Cooling Tower Capacities Round shape cooling tower gives 100% cooling efficiencies it’s give good appearance flow rate from 5 M³/Hr To 550 M³/Hr gives differences in temperature 4ºC To30 ºC Availability of Capacities from 5 TR T0 600 TR. Features The bottle shaped FRP cooling tower is utilized in several industries and has the following features. All the components have a modular and compact design The casing and the design has an exclusive circular design. Therefore no impact of the direction of prevailing wind is encountered. This FRP water cooling tower has a very efficient sprinkler head system that is rotative and is made of aluminum alloy Axial flow fans that are designed aerodynamically with adjustable pitch are used The bottle shaped FRP cooling tower helps conserve power Quiet operation is ensured The sump is given easy access with a galvanized mesh of hot dip. This is done to avoid entry to foreign objects into the water basin The possibility of corrosion and rust gets minimized due to the framework steel components that are galvanized hot dip Though the cooling tower maintenance is not difficult, it is important. Cooling Tower Maintenance Efficient treatment of water Prevent scale deposits Do way with or clean spray nozzles that get clogged Adequate air flow should be ensured Adequate performance of pump also should be assured Round shape Cooling Towers Spares PVC Fill : A good quality fill and is of long life too. Drift Eliminator: The carry over losses due to moisture drops. Sprinkler: Due to the even water distribution over the honey comb fills. Fan: flow type fan that is aero dynamically designed is of well balanced construction. we have availability of FRP fan and Aluminum fan

Panel Cooler

20,000 - 50,000 Per Piece

1 Piece(s) (MOQ)

tube bundle heat exchangers

Get Price Quote

In nuclear power plants called pressurized water reactors, large heat exchangers called steam generators are two-phase, shell-and-tube heat exchangers which typically have U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most shell-and-tube heat exchangers are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. In a single pass heat exchanger, the fluid goes in one end of each tube and out the other. In Offshore Industries, Water Makers are made up of U tube Heat Exchangers. To Maintain the Lower Pressure Drop in High Tube Length. A tube bundle heat exchanger with baffles is disclosed wherein a tube bundle is housed within an inner casing which is acted upon from both the inside and the outside by a heating medium A multiple tube bundle heat exchanger includes axially opposite tube plates, a housing, and a plurality of tube bundles disposed between the tube plates. Each of the tube bundles is an independent tube bundle subassembly forming an integral unit having at least one heat exchanger tube with two axial tube ends.

Rcc Cooling Tower

Get Price Quote

We are Specialist in the establishment of Reinforced Concrete Cooling Towers. We Do RCC Cooling Towers Design and Construction for both in Cross Flow RCC Cooling Towers and Counter Flow RCC Cooling Towers, With Long life Compare to FRP and Timber Cooling Towers. RCC Towers made of Concrete cell. All Internal Parts are As per Other Cooling Towers. The Performance of Cooling Tower is Pre Determined and Over Designed based on Long Life Approach. Also Our style of construction is Completely User Friendly and Attractive suitable for huge wate flow application plants like RCC Cooling Tower Applications power plants, sugar plants, Cement plants, Boilers and water treatment plants etc., RCC COOLING TOWER DATA We manufacture high quality Induced draft Cooling Tower in RCC Construction also both in Cross Flow and Counter Flow design that require easy maintenance and low recycle cost. As a result our industrial RCC cooling tower is highly demanded by a number of companies. With our hard work we have been able to enlist ourselves among the leading RCC cooling tower manufacturers and exporters in India. Since the structure of Cooling Tower is complete with RCC, the tower life will be more than timber as well as FRP. Available in two designs: Cross Flow design Counter Flow design Capacity of RCC Cooling Tower : The ranges of our RCC Cooling towers are 500 m3/hr to 3000 m3/hr per Cell Applications : Power Plants Sugar Plants Chemicals Plants

U Bundle Heat Exchanger

Get Price Quote

The U-tube head (U) is a very simple design requiring a bundle of U tubes, only one tube sheet, no expansion joints, and no rear-end head at all, allowing easy removal of the bundle. The thermal stress problem is eliminated because each tube is free to expand/contract independently. One disadvantage is, individual tube replacement is not possible except in the outer rows, and an even number of tube passes is required. Some tubes are lost in the center due to HEAT EXCHANGERS 17.7 tube bend limit, and tube side mechanical cleaning of the bends is difficult. Flow-induced vibration could be a problem for tubes in the outermost row. It is the lowest-cost design because there is no need for the second tube sheet.

Air Cooled Aftercooler

Get Price Quote

Our organization is listed amidst the reputed manufacturers of Air Cooled After Coolers. These products are suitable to be used in removing heat created after the compression. Furthermore, our range is favored for its ability to retain water and approximately doubles with rise in temperature of 11°c. On cooling, moisture can be collected in the air network network and associated equipment. Our range also facilitates in washing the lubricants and creating possible freezing problems. We also provide After Cooler (Air Cooled), which is available in both water cooled & air cooled models. Our range can be availed in 50 to 1000 cfm for operating pressure from 7 to 35 kg/sq. cm. These products also have moisture separators of demister/baffle & centrifugal types. This facilitates in removing the moisture immediately after the after cooler.

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger is one of the simplest form of Shell and Tube Heat Exchangers. Here, just one pipe inside another larger pipe. To make an Unit very Compact, The Arrangement is made Multiple Times and Continues Serial and Parallel flow. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface.This is also called as a hairpin heat exchanger. These are may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. In some of the Special Cases the Fins also Used in Tube side.

Tube Heat Exchanger

15,200 Per Piece