Inter Cooler

Get Price Quote

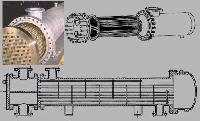

Shell and Tube Heat Exchanger

Get Price Quote

Target Equipments design of the shell and tube heat exchanger is quite complex. The tubes used internally are deliberately of various shapes and design to obtain different outcomes. While a few of the tubes may be plain, others may come finned longitudinally or horizontally. Additionally, the tubes can also be of various materials and thermal conductivity. For instance, Target equipments can be designed from carbon steel, stainless steel, cupronickel, copper or brass. Testing Of Heat Exchanger Owing to the complex nature of the shell and tube heat exchangers, regular inspection of the equipment is necessary. This can help to assess the thickness of the tube walls that are prone to pitting, erosion and corrosion over time. The status of the whole bundle of tubes may be charted and assessed through a thorough inspection with the help of a device known as Internal Rotary Inspection System that functions via ultra tonic testing and also has a non-destructive nature Specification Features Materials we used for Shell :, Copper, Carbon steel, stainless Steel sizes up to 20000 mm, Tubes Copper, Brass, Cupro-nickel , Carbon Steels in sizes from 6 mm to 50 mm OD, Stainless Steels, Tube Sheets: Carbon Steel, Stainless Steel, Brass etc. Channels and Cover : Carbon Steel, Stainless Steel, Case Iron, Brass etc. Gaskets : Rubber, Compressed Application Chemical, Petrochemical, Fertiliser. Thermal Power plants, Refrigeration Plants, marine Engines, Turbines, Hydraulic Systems, Sugar Machinery .

Best Deals from Heat Exchangers

Shell and Tube Heat Exchanger

Get Price Quote

Gireesh shell and tube heat exchanger is the most common type of heat exchanger designs. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, etc. process liquid or gas cooling process or refrigerant vapour or steam condensing process liquid, steam or refrigerant evaporation process heat removal and preheating of feed water thermal energy conservation efforts, heat recovery compressor, turbine and engine cooling, oil and jacket water hydraulic and lube oil cooling

Spiral Heat Exchanger

50,000 - 100,000 Per Piece

1 Piece (MOQ)

Shell & Tube Heat Exchanger

Get Price Quote

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. We are a dependable Manufacturer, Supplier and Exporter of Shell & Tube Heat Exchanger. Also, these Shell & Tube Heat Exchangers are designed as per the leading-edge technology. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Shell & Tube Heat Exchanger, which we offer, can be operated within a temperature range of -40oC to 150oC on either side. However, differential temperature should not exceed 120oC at any point. All the Shell and Heat exchangers can be use pre-dominantly under full vacuum, provided differential pressure does not exceed 3 bar g. Details Type: Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double PipeCapacity Range : As per Customer requirementShell Diameter : 4� to 125�Tube Length : 3� to 40�Tubes : Plain, Integrally Finned or U-TubeNo of Passes: Single, Double & Four passesM.O.C. Tubes : Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminium, Titanium, Tantalum, Hastolloy, Aluminium Bronze, Monel, Duplex, CupronickleShell : Carbon Steel, Stainless Steel, Copper, Monel. Brass, AluminiumChannels : Carbon Steel, Stainless Steel, Gun Metal, Cast Iron, Brass, Cast Aluminium, Alloy Technical Information : All the Shell & Tube Heat Exchanger are constructed with 12 mm OD, 1.5 mm thick glass tubes. These tubes are arranged in triangular pitch of 21 mm. Baffles are provided with 30% cut at a distance of approximately equal to inner diameter of shell. Generally, PTFE baffles are used in Glass shells and PP baffles in Metal Shells. Our Applications DG set for all capacitySpace heatingRefrigerationAir conditioning Power plantsChemical plantsPetrochemical plantsPetroleum refineriesNatural gas processingSewage treatment

Cooling Towers

Get Price Quote

World Cooling Towers high quality FRP cooling towers in India which is helps to reduce the excess heat from various oindustries and commercial buildings. Our ccoling towers system are manufactured with belt-drive motor, which is designed to minimize power consumption up to 20-25%. Get affordable and best cooling tower solution in India with 1 year warranty.

Air Cooled Heat Exchanger

Get Price Quote

Our air fin coolers successfully reduce the temperature of the circulating fluid inside the finned tubes by pushing air over the tubes. We customize the air cooled heat exchangers as per the client’s requirements and needs.The finned tube bundles in the exchanger are provided by us in modular construction so that it is easy to transport. The types of headers offered by us are Plug Header, Manifold header, Welded Bonnet Header, Plug and pipe header etc. ‘G’ type Embedded Fins, ‘L’ type Wrap-On Fins.

Kettle Reboiler Type Heat Exchanger

Get Price Quote

Kettle reboilers are very simple and reliable. They may require pumping of the column bottoms liquid into the kettle, or there may be sufficient liquid head to deliver the liquid into the reboiler. In this reboiler type, steam flows through the tube bundle and exits as condensate. The liquid from the bottom of the tower, commonly called the bottoms, flows through the shell side. There is a retaining wall or overflow weir separating the tube bundle from the reboiler section where the residual reboiled liquid (called the bottoms product) is withdrawn, so that the tube bundle is kept covered with liquid.Kettle reboilers are reliable in that they can handle high vaporization of up to 80 percent and are easy to maintain. The liquid from the bottom of the tower flows through the tube bundle and exits as condensate. A restraining device (baffle) controls the liquid level over the bundle. Specifications : Proper reboiler operation is vital to effective distillation. In a typical classical distillation column, all the vapor driving the separation comes from the reboiler. The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides the heat required for the vaporization. Applications : The high level of vaporization makes it prone to fouling, and these reboilers are expensive due to their large shell size and maintenance. Advantages : Reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation.

Brazed Plate Heat Exchanger

Get Price Quote

Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. The SB-Series features corrugated plates that produce highly turbulent flow in a true counter-current direction. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance.

aluminum heat exchanger

Get Price Quote

A heat exchanger is an ingredient of equipment built for well-organized heat transfer from one medium to another. A solid separation may separate the media, so that they never mix, or they may be in unswerving contact. They are lengthily used in space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, and sewage treatment. The characteristic example of a heat exchanger is found in an interior combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and airflows past the coils, which cools the coolant and heats the incoming air.Rolling sheet ingots shed from molten aluminium, then re-rolling on sheet and foil rolling mills to the preferred thickness, or by continuously casting and cold rolling manufacture aluminum foil. To maintain a steady thickness in aluminum foil production, beta radiation is passed through the foil to a sensor on the other side.

air cooled aftercoolers

Get Price Quote

We are dealing in air cooled after cooler to reduce / cool the compressed air temperature to desired level, so the condensation takes place and vaporized moisture and oil in the air gets converted to liquid droplets which further separated by moisture separator.

Heat Exchangers

Get Price Quote

We are Supplier of this product.

Finned Tube Heat Exchanger

Get Price Quote

JC Finned Tube Heat Exchangers are specially designed and developed by our team and for your applications using Europe Technology ie., with Spiral Wound Finned Tubes and also the heat exchangers are extremely efficient in recovery of heat without an supplementary segment change. The types of FTHE are, Stainless Steel, Copper, Brazed, Finned Coil, Aluminium.

Air Cooled Condenser

Get Price Quote

Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Plate finned type Heat Exchanger

Get Price Quote

We manufacture and export all types of industrial heat exchanger in INDIA. The heat exchangers are commonly useful in industries where the fluids have small chances of fouling. Our heat exchangers can be made in a various of materials. plate fin heat exchanger manufacture are the same for all sizes and all materials. Plate finned type Heat Exchanger Flow Types are Parallel flow, Counter flow and Cross flow. Plate finned type Heat Exchanger Material of Construction : Stainless steel casings, Copper Alloy tubes, Aluminum Fins or Foils, Copper Tubes, Carbon steel Casings Plate Finned Type Heat Exchanger Applications Refrigeration Condensers Air Coolers Air Heaters Natural gas liquefaction Air Separation Steam Condensers Ammonia production Oil refineries Food Industries and Processing Industries Nuclear engineering Syngas production Aluminium Plate Finned Heat Exchangers : The heat exchangers are developed by vacuum brazing technology and the heat exchangers as single units or as manifolded assemblies, isothermal reactors for chemical Plants and Coil wound heat exchangers and petrochemical industry plants. Plate Finned Heat Exchangers Comparison with Shell and Tube Heat Exchanger. A Plate finned heat exchanger with 6 fins/cm provides approximately 1,300 m2 of surface per m3 of volume. This heat exchanger would be approximately 10% of the volume of an equivalen shell and tube heat exchanger with 9 mm tubes.

Plate Heat Exchangers

Get Price Quote

We manufacture and supply highest quality range of plate heat exchanger using the most advanced technology for a wide series of heat transfer applications used in various industries such as chemical industry, offshore, oil and gas, petrochemicals power plants, pulp and paper, steel, zinc and aluminium, sugar, vegetable oil, breweries / distilleries, dairy / beverages and others. The difference lies at plate design, sealing technology, capacity range, product range etc. We always continue to improve our Plate heat exchanger to give total customer's satisfaction. Plate Heat Exchanger Features High heat transfer coefficients Optimized heat recovery Compact constructions No mixing of product Flexibility to change plate arrangement and to add / remove plate Easy maintenance and suitable for CIP, plate pack easily accessible. Plate Heat Exchanger A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat system in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible. Plate Frame Heat Exchanger Application Plate Frame Heat Exchanger Cleaning Plate and Frame Heat Exchangers Animation Plate and Frame Heat Exchanger Approach Plate finned type Heat Exchanger Brazed Plate Heat Exchangers Plate Heat Exchanger Design The concept behind a plate heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger. The plate heat system (PHE) s was invented by Dr Richard Seligman in 1923 and revolutionized methods of indirect heating and cooling of fluids. Plate exchanger one is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat system. Advances in gasket and brazing technology have made the plate type heat system increasingly practical. In HVAC applications, large exchangers of this type are called plate-and-frame; when used in open loops, these heat system are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat system, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat systems also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves. Liquid foods such as milk, fruit juices, beers, wines, and liquid eggs are pasteurized using plate-type. Wine and fruit juices are normally deaerated prior to pasteurization in order to remove oxygen and minimize oxidative deterioration of the products. Plate Type heat exchanger consist of a large number of thin, vertical steel plates that are clamped together in a frame. So it may called as Plate and Frame. We manufacture Plate Heat Exchanger that are used in dairy, pharma and biotechnology, beverages, brewery, chemical and power sectors. PHE plates are available in MOC AISI 304, AISI 316, AISI 316L, Titanium, Hast alloy, Monel in range thickness from 0.5mm to 0.9mm. It is suitable for handling fluid from 100 LPH to 3.5 Million LPH. The plate heat exchanger sare available in herring bone, free flow and semi welded construction and depending on application respective plates are selected. Plate heat exchangers - Bolted design (plate and frame) Heat transfer plates are characterized by optimum embossing resulting in high heat transfer coefficients. This permits low-cost and optimum adoption to the respective application conditions Our product range includes single-pass and multi-pass plate heat exchangers with heat exchange surface up to 1500 m². Plate Heat Exchanger Technical data: heat exchange surface per plate: 0,04 - 2,50 m² max. design pressure: 25 bar max. design temperature: 170°C Plate Heat Exchanger Safety:Our plates are provided with double gaskets at the inlet and outlet which prevent mixing of the two media. If designed as safety heat exchanger, double plates are provided with a special sealing system. Plate material: standard: stainless steel 1.4301/AISI 304, 1.4401/AISI 316 optionally: 1.4539, 254 SMO, titanium Gasket material: NBR (nitrile-rubber) EPDM (ethylene-propylene-rubber) Viton (fluorine-rubber) Further materials on request Special series: Safety heat exchangers (FPSS) Stainless steel design for food and FDA applications Compact double PHE-units including cocks and valves Design with welded cassettes (FPG)

Shell & Tube Heat Exchanger

Get Price Quote

A heat exchanger is a device used to transfer heat between one or more fluids . It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. The simple design of a shell and tube heat exchanger makes it an ideal cooling solution for a wide variety of applications. One of the most common applications is the cooling of hydraulic fluid and oil in engines, transmissions and hydraulic power packs.

Heat Exchanger

Get Price Quote

Dear sirmadam, greetings for the day… we jc equipments pvt ltd take pleasure to introduce ourselves as one of the leading designers, manufacturers & exporting of all kind of cooling towers,heat exchangers pressure vessels columns, storage tanks, air cooled condensers, etc.. In india. Jc equipments pvt ltd started in the year of 1989. We have wide knowledge in this field and we have regular customers throughout the world. We are authorized manufacturers of asme and we have “u, s & r” stamp certification also. We are corporate member of cti, usa. We are a world class manufacturers and we never compromise in quality. We assure our product will be best quality and competitive price. Herewith we have enclosed the product profile for your kind reference. Kindly refer the attachment. Looking forward your valuable enquiry for us to quote our best and competitive offers, with assuring you of our best quality and prompt service at all times.

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger, in its simplest form is just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface. The pipes are usually doubled back multiple times as shown in the diagram at the left, in order to make the overall unit more compact.

Air Cooled Heat Exchanger

Get Price Quote

We are designed and developed the air cooled heat exchanger (ACHE) for various types of application. We are specialized air cooled heat exchanger manufacturer of Thermal Power Plants and also an air cooled heat exchanger is used to cool fluids with ambient air. Air cooled heat Exchangers are same In the Functions of Finned Tube Heat Exchanger. Finned Tubes are most of very significant part of the Heat exchanger which affect the efficiency of the Air Cooled Heat Exchanger. Applications: »Process Coolers / Condensers Cooling Tower Fans Cooling Water Coolers Air Cooler Fans Air Cooled Heat Exchanger for Oil & Gas Production Gas Coolers Gas Compressor Inter / After Coolers Air Cooler Fans Air Cooled Heat Exchanger for Power generation Cooling Tower Fans Steam Condensers Seal / Lube Oil Cooler Closed-Loop Cooling Water Coolers Geothermal Plant Condensers Air Cooler Fans Turbine lube oil coolers Turbine intercoolers Advantages: »The multi-sharp edge fans are statically adjusted to improve vitality effectiveness and have Automatic Variable Pitch for elite and sturdiness. Paharpur’s prestigious apparatus reducers, accessible in numerous choices, are intended to convey superior under requesting mechanical conditions.

Finned Tube Heat Exchanger

Get Price Quote

We are offering Plate-fin heat exchanger is one of the most efficient compact heat exchanger. The gaps between constitute a fluid layer. A core is made of a great number of layers. The exchanger can be made of one or more cores. The number of plate and fin layers, the size of the plates and fin, the height of the fin and the type of fin are engineered for optimum performance. The core is assembled (stacked) and typically held together by tack welding a weld rod to the top and bottom layer of the core. The stacked core is then placed within a fixture that exerts force on the individual pieces to keep them in contact. The part is then vacuum brazed in an environmentally-controlled room to ensure high quality and reliability. After brazing the core is typically heat treated or aged in order to increase its strength. Manifold ducting and mounting brackets are then welded in place as required, and any required paint or coating can be added.

Double Pipe Heat Exchanger

Get Price Quote

A double pipe heat exchanger is one of the simplest form of Shell and Tube Heat Exchangers. Here, just one pipe inside another larger pipe. To make an Unit very Compact, The Arrangement is made Multiple Times and Continues Serial and Parallel flow. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface.This is also called as a hairpin heat exchanger. These are may have only one inside pipe, or it may have multiple inside tubes, but it will always have the doubling back feature shown. In some of the Special Cases the Fins also Used in Tube side.

Timber Cooling Tower

Get Price Quote

We are leading manufacturer of timber type cooling towers.It is mechanical strength, durability and high efficiency. Manpower with vast specialized experience in Timber manufacturing is back bone of the organization. We have with us persons who have been entirely responsible from concept to final product manufacturing. We have major time tested development that has been incorporated in standards. Our CCT timber are atmospheric and mechanical cooling towers. Atmospheric towers are only for smaller capacities and mechanical draft towers are for higher range. Induced draft cooling towers are efficiency and popular due to sucking of air from the tower and exhaust at the top or side. The timbers are made out of pine or chirr wood after properly seasoned and chemically treated with arsenic chromate to with stand its life against biting, fungus and termite etc. Timber Cooling Tower Product Range 1. Wooden Single Flow and Double Flow induced Draft Cross Flow. 2. Direct Drive System. 3. Reduction Gear Box Drive Suystem. 4. Counter Flow Square / Rectangular Induced / Forced Draft Towers. 5. Packaged Wooden Double / Single Flow Induced Draft Cross Flow. 6. Fan-less Induced Draft Wooded Cooling Tower [ Atmospheric Natural Draft Cooling Towers]. 7. Re-Inforced Concrete Cooling Towers. 8. Spares For any Type and Make of Cooling Towers. Timber Cooling Tower Concepts 1.1 Economy in Operation Our Timber Cooling Towers are designed for the highest effieiency at the lowest operating cost. Fans gear boxes, fill and drift eliminators are optimized to deliver maximum cooling with minum applied horsepower for lower operating cost. 1.2 Best Performance Our Timber Cooling Towers are providing more wetted surface area for uniform water distribution and higher heat trasfer rate. 1.3 Architectural Compatability Our Timber Cooling Towers are designed to a low profile. So the appearance and general configuration blends harmoniously with surroundings. Performance and attractive appearnance are demanded. 1.4 Maintenance Free Our Timber Cooling Towers are used maintenance free materials throught the tower. The materials are used in structural and functional components, all steel is hot-dipped galvanized after the fabrication. Timber Cooling Tower Technical Specifications 2.1 Structure Main structural components and other light sections machined with selected preservative timber. And it is designed for operational load and wind pressure of 250 kg/m2 of projected area in any horizontal direction. The structural timbers are made out of pine or chirr wood after properly seasoned and chemically treated to withstand its life against biting, fungus and termilte etc., 2.2 Fills Different types of preservative treated wooden splash bars, PVC bars are used depending on applications. Different types of afill materials with different shapes area available according to suited design of applications. Fill bars are designed to offer maximum splash surface and wetted surface resulting in a high heat transfer rate. 2.3 Water Distribution in Timber Boiler waterproof plywood [marine grade] / treated timber are used for hot water chamber. For uniform distribution box through which the water is equally distributed in the hot water basin. Basins are provide with combination metering orifices / diffusers which distribute water uniformly. 2.4 Fan Cylinder in Timber Fan cylinders designed in aero-dynamically the design allows close tolerance on fan blade tip clearance plus less interference of air passing through the tower. Fan cyclinder made by HDG Steel / Fiberglass reinforced polyester. 2.5 Nozzles in Timber The Target Nozzles used in the hot water chambers are designed to deliver required water evenly. The nozzle eliminates the need for a deck to provide complete water distribution throughout the fill area. It is highly resistant to temperature and weathering damage the water is distributed under gravity. 2.6 Louvers in Timber The standard cladding of profile corrugated asbestos cement sheet, the joints of which are lapped to shed water only inside the cooling tower. Louvers are supported and positioned by combination tower columns and louvers supports. 2.7 Drift Eliminators in Timber Specially designed eliminators from single pass pattern to 4 pass pattern of various materials are provided according to applications to minimize bleed of losses. Two pass herringbone drift eliminators trap entrained moisture causing it to drain into the cooling tower basin. 2.8 Mechanical Equipments in Timber The mechanical equipments are used in our cooling towers are specially designed for long lasting life. Multiblade fans are cast aluminim for smooth quiet operation, Low Noise, high volumes of air High efficiency, and low power consumption adjustable pitch blades are used for maximum utilization of applied horsepower. Fans are driven by an electric motor coupled to a spiral bebel gear box through a dynamically balanced tubular drive shaft. We are using special enclosed motors with weather proof and in IP-55 construction to withstand moist air stream. 2.9 The External Casing in Timber The External Casing is corrugated cement sheets fitted vertically and joints are lapped and sealed for water tightness. Corners are covered by absestos sheets. Also using FRP Sheets for External casing in Timber Cooling Towers. 2.10 Direct Drive Sytem in Timber These are lower and medium capacity cooling towers and upto 10 feet dia fan are supplied with multiblade cast aluminum adjustable pitch fan with M.S. Fabricated HDG Hub and SS Hardware. Motor provided with the system is special low RPM totally enclosed vertical Flange type is supplied with the cooling tower. The motor is totally weather proof in IP-55 construction suitable for heated and humid atmosphere. In the above model fan is directly coupled wiht the slow RPM motors [vertical flange mounted with sealed top and enlarged threaded shaft] 2.11 Reduction Gear Box Drive System in Timber Bigger capacity cooling towers are supplied with fan assembly driven through reduction gear reducer of spiral bevel type with the help of non-lubricated balanced drive shaft with flexible links. Fans are driven by an electric motor coupled to a gear box through a dynamically balanced tubular drive shaft. The compelete equipment will be supported on a single fabricated mild steel frame adequately weather proofed. Counter Flow Towers Packaged Wooden Cross Flow Cooling Tower Fan Less Natural Draft Cooling Towers Timber Cooling towers are usefull for chemical plants, air conditioning plants, induction furnace, injection moulding machine, chilling plants, oxygen plants. diesel generating sets and heat exchangers. And also for steel industries, cement industries, chemical industries, water effuluent treatment industries. Our Timber are designed for the highest efficiency at the lowest operating cost. Fans, gear boxes, fill and drift eliminators are optimized to deliver maximum cooling with minimum applied horse power for operating cost. Our Timber provide more wetted surface area for uniform water distribution and higher heat transfer rate. The structural timbers are made out of pine wood (or) chirr wood after properly seasoned and chemically treated to with stand its life against biting, fungus and termite etc., Different types of preservative treated wooden splash bars, PVC bars are used depending on applications. Different types of fill materials with different shapes are available according to suited design of applications. Fills are designed to offer maximum splash surface and wetted surface resulting in a high heat transfer rate. The wooden fills are supported on FRP/SS grids which assure positive & permanent positioning and to assure uniform water distribution. We export and having many clients at USA UAE Dubai and Abudhabi. Be Sociable, Share!

Round Cooling Tower

1 Per -

Round type cooling tower are designed to resist severe vibration, wind load and to resist corrosion. The cooling system consists of Honey comb PVC fills. https://www.welltechcoolingsystems.in/round-cooling-tower/

Heat Exchangers

Get Price Quote

Heat exchangers are equipment used to transfer the heat from one process fluid to another fluid by either direct contact or indirect contact. Heat exchangers are intended for heating, cooling, condensing , evaporation and boiling of process fluids used in process industries.

Air Cooled Heat Exchanger

Get Price Quote

Air Cooled Heat Exchanger, Air Cooled Condensers, Oil Coolers

Heat Exchangers

Get Price Quote

Heat exchangers are equipment used to transfer the heat from one process fluid to another fluid by either direct contact or indirect contact. Heat exchangers are intended for heating, cooling, condensing , evaporation and boiling of process fluids used in process industries. We offer following in house design and fabricated heat transfer equipments.

Air Cooled Heat Exchanger

Get Price Quote

Air Cooled Heat Exchanger, Plate Type Heat Exchanger

Timber Cooling Tower

Get Price Quote

Timber Cooling Tower, Wooden Cooling Tower, Honeycomb Pvc Fills

fibre cooling tower

Get Price Quote

fibre cooling tower, aluminium fans, aluminium sprinklers, PVC Fill