Water Cooling Tower

100,000 Per Piece

1 Piece (MOQ)

Chemical Treated Wooden Cooling Tower

Get Price Quote

1 Piece (MOQ)

Best Deals from Heat Exchangers

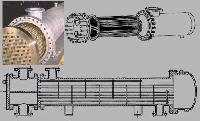

Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchanger

Get Price Quote

PVC Cooling Tower Fills

175 Per No

We are manufacturing all types of cooling towers. FRP cooling tower round and square type, cross-flow cooling tower, wooden cooling tower, dry cooling towers, natural draft cooling tower, Heat exchangers, oil cooler, Chillers, Three Phase Industrial Electrical Motor and supplying all types of Cooling towers spares cooling tower service,

Frp Cooling Tower

130,000 Per Piece

1 Piece (MOQ)

Gasketed Plate Frame Heat Exchanger

30,000 Per Kilogram

the gasketted plate and frame heat exchangers that are made by us are premium in quality which is made using the best variety of raw materials. This plate heat exchanger is corrosion resistant and can easily be installed anywhere. Plate and frame heat exchangers comes in a compact design that assures greater efficiency, low hold-up volume, expandability and flexibility, easy maintenance, and close temperature approaches. high heat transfer coefficients, ensuring the designed surface area is kept to a minimum. compact design, saving on plant room space requirements. ease of maintenance. exchanger outputs can be increased by adding additional plates. exchangers can achieve high cross over temperature profiles. low standing losses in comparison with other exchanger types.

Heat Exchangers

Get Price Quote

Our Heat Exchangers recover the heat without phase change, thus are widely demanded in the global markets. Used for transferring heat amongst different mediums, our Heat Exchangers are offered at competitive prices. The company is the chief Heat Exchangers Manufacturer, Exporter, and Supplier in India. Applications PowerEngineeringAutomotive Used For GasesFluidsSteam

Shell & Tube Heat Exchanger

Get Price Quote

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. We are a dependable Manufacturer, Supplier and Exporter of Shell & Tube Heat Exchanger. Also, these Shell & Tube Heat Exchangers are designed as per the leading-edge technology. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Shell & Tube Heat Exchanger, which we offer, can be operated within a temperature range of -40oC to 150oC on either side. However, differential temperature should not exceed 120oC at any point. All the Shell and Heat exchangers can be use pre-dominantly under full vacuum, provided differential pressure does not exceed 3 bar g. Details Type: Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double PipeCapacity Range : As per Customer requirementShell Diameter : 4� to 125�Tube Length : 3� to 40�Tubes : Plain, Integrally Finned or U-TubeNo of Passes: Single, Double & Four passesM.O.C. Tubes : Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminium, Titanium, Tantalum, Hastolloy, Aluminium Bronze, Monel, Duplex, CupronickleShell : Carbon Steel, Stainless Steel, Copper, Monel. Brass, AluminiumChannels : Carbon Steel, Stainless Steel, Gun Metal, Cast Iron, Brass, Cast Aluminium, Alloy Technical Information : All the Shell & Tube Heat Exchanger are constructed with 12 mm OD, 1.5 mm thick glass tubes. These tubes are arranged in triangular pitch of 21 mm. Baffles are provided with 30% cut at a distance of approximately equal to inner diameter of shell. Generally, PTFE baffles are used in Glass shells and PP baffles in Metal Shells. Our Applications DG set for all capacitySpace heatingRefrigerationAir conditioning Power plantsChemical plantsPetrochemical plantsPetroleum refineriesNatural gas processingSewage treatment

Ductable Panel Coolers

30,000 - 200,000 Per Piece

1 Piece(s) (MOQ)

We are offering ductable panel coolers, ductable air-conditioners are used when the volume of the panel area to be cooled is large and the cooling requirement is high. Here the panel doors may not be able to host large capacity panel mountable coolers as they would weigh more. To offset this disadvantage a ductable air conditioner is recommended. A ductable air-conditioner with double inlet centrifugal blower eliminates hot pockets of air inside the panel there by uniformly cooling the panel components faster. These units are equipped with castors for mobility.

Air Preheater

Get Price Quote

PWO Plate Coolers Brazed

Get Price Quote

10 Piece (MOQ)

PWO – Plate Coolers brazed Unique and maintenance-free – for efficient cooling The PWO Plate cooler is a compact and light-weight oil-water cooler with high cooling capacity despite its small dimensions. It consists of corrugated channel plates enclosed by a back and front cover plate. The channel plates are pressed and vacuum-welded in an automatic procedure subject to very strict quality controls. The unique plate design provides highly turbulent flow conditions throughout the cooler, the key to efficient cooling. Turbulences prevent deposits from forming to such an extent, that the PWO cooler is virtually maintenance free.

Panel Cooler

20,000 - 50,000 Per Piece

1 Piece(s) (MOQ)

Round Cooling Tower

Get Price Quote

Cooling Tower

Get Price Quote

We are one of the widely acclaimed manufacturers and suppliers of Cooling Towers. The offered cooling tower is a versatile heat rejection device, which is used to reject the waste heat to the atmosphere. Our supplied cooling tower employs fresh air for cooling the atmosphere and environment. The offered cooling tower is available at very cost effective and affordable market rates.

Water Cooled Aftercooler

18,000 Per Piece

Heat Exchanger

60,000 Per Piece

Our firm is leading voice for exporting and supplying of Heat Exchanger to our esteemed consumers. W

Inter Cooler

Get Price Quote

Buyers can order our products in bulk, as we maintain year around availability. In addition, we have reliable transportation system to make timely delivery. Safety of the products is the prime concern of the organization. Thus, we store the entire lot in a capacious and well-structured warehouse till the delivery of the orders.

Brazed Plate Heat Exchanger

150 - 5,000 Per kg

Air Cooled Condenser

25,000 Per Piece

JC Fixed Tube Sheet Heat Exchanger

Get Price Quote

We manufacturer of Fixed Tube Sheet heat exchanger in India as per your requirement and as per the market standards. This JC FIxed Tube Sheet heat exchanger is useful for hight pressure and high temperature based applications. Also for chemical industries and all refinery units are using our Fixed Tube shee heat exchanger. This type of heat exchanger is employed where even slightest intermixing of fluids can not be tolerated. The inside tube sheets are fixed as its name implied.

COOLING TOWERS AND HEAT EXCHANGERS

Get Price Quote

We at Unitek Hydraulics offer cooling towers and heat exchangers for industrial processes. The cooling towers are designed to cool industrial recycled process water from 50 degrees to a lower temperature. The inlet water pressure rotates the sprinkler to disperse water uniformly over the media. Once the air passes through the fill media, portion of the water is evaporated and removes heat from the remaining water. Cold water is then collected at the sump and is recirculated at the source. It finds application in many industries such as air compressor, AC plant, diesel and steel factories. We also offer a wide range of heat exchangers that are used to change the status of materials from liquid to gas and from gas to liquid. We cater to a gamut of industries such as chemical, pharmaceutical, paint and coating, power plants, biotech industries and petroleum industries. Our machines are recognised for their sturdy construction and optimum performance. Features Uniformity in water dispersion through rotary sprinkler Sturdy construction Low power consumption Optimum performance Robust

Brazed Plate Heat Exchanger

Get Price Quote

We provide high quality Compact design Three way design for heat pumps Higher Heat Transfer High corrosion resistance Low investment costs for BPHE Simplify maintenance and repair with BPHE Versions for standard and high pressure operation

KETTLE TYPE REBOILER

Get Price Quote

Stripping hydrogen sulfide and ammonia from refinery sour water prior to subsequent reuse or wastewater treatment calls for highly reliable, corrosion-resistant, low-fouling equipment. BCS heat exchangers do the job, minimizing fouling and corrosion problems in refinery sour water strippers in refineries world-wide while maximizing energy efficiency and uptime. Energy is recovered when sour water is preheated before the stripper by means of stripped water. The more energy recovered in this service, the less energy needs to be provided to the stripper reboiler in terms of steam. The stripper reboiler is generally designed as a kettle-type reboiler. These typically require a large temperature difference between the boiling media and the steam. This means that a higher pressure steam is required to run the reboiler. When our exchangers are used as rising film thermosiphon reboilers for the sour water stripper column, a temperature difference of less than 10°C is possible to initiate boiling and create natural circulation through the reboiler. This often means that it is possible to use more readily available low-pressure steam instead of medium-pressure steam. Applications : Chemical Plants Refineries Reboiler Distillation Towers Kettle Reboiler Features: We design Kettle Reboiler as per ASME SEC VIII Div-1 standards and TEMA standards. We analyze and calculated the Mechanical and Thermal Design. Phase Exchanger constructed by us is in accordance to the ASME Sec-II Part A & B We have qualified welders for all types of welding joints for structural work. We have our own facility for POST WELD HEAT TREATMENT, NDE. We also provide Hydro Test, Pneumatic Test facilities.

Modular Cooling Tower

Get Price Quote

We are offering modular cooling tower, gireesh are specialized in manufacturing a wide range of modular cooling tower, which are manufactured using computer based design techniques. In our range of square cooling tower, hot water to be atomized ejected through the nozzle and thoroughly mixed with air and resultant better performance. features • stationery non-clog nozzle for easy maintenance • pvc fills for larger contact surface area • weather proof ip 55 flange motors with extended craft • auto fill float • aerodynamically designed air inlet louvers made of extruded pvc for least water losses maintain ace and spares • fixed pp non clog type virgin quality nozzle atomized (sprays) the hot water broken into smaller particles there itself cooling takes place • no such hassles • no moving parts • nozzles are virgin materials. • drift eliminators made out of pvc honey comp structure in construction packed tightly above the nozzle.

Coil Type Heat Exchanger

Get Price Quote

We are the leading manufacturers of Coil Type Heat Exchanger in India. A Coil Type Heat Exchanger is the most common type of heat exchanger in all Industries. Mostly used in higher-pressure and Higher Temperature applications. The Coil Heat Exchangers can have a methods of structuring theory with module package of heat exchangers. It may be design with gas and liquid flow for the Coil Heat Exchangers. Evaporation is not possible in the Coil Heat Exchangers processing.To guide the flow in the exchanger you can use a cylinder. You can also design a coil type heat exchanger without any displacement body. The coil may consist of a maximum of 5 parallel flown-through tubes.Shell-side flow is always forced flow. Flow direction might be cocurrent or countercurrent.The theory of Coil Heat Exchangers are presented in the VDI Heat Atlas and the HEDH (Heat Exchanger Design Handbook) as well as in special research reports.This product can also set the program parameters so that the program will only calculate with standard tube and shell dimensions (default values). The Process will enables the constructor to optimise times of delivery or to reduce costs for storage by limiting the assortment of goods. Media must be single phase (liquid or gaseous) or condensing pure substances (pure substance con-densation, isothermal condensation). The properties of the used media are provided by LV property modules and are determined for mean temperatures and pressures. Condensation of multi-component mixtures is not possible with COIL.

Air Cooled Condenser

Get Price Quote

Air cooled condenser is a heat-exchange system. Conversely, the vapour can be fed through the tubes with the coolant water or air flowing around the outside. Air cooled condenser, the coolant flows through the tube side and distilled vapor through the shell side with distillate collecting at or flowing out the bottom.Air cooled condenser are also used in industrial-scale distillation processes to cool distilled vapor into liquid distillate.

Air Cooled Condenser

Get Price Quote

Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Air Cooled Condenser

Get Price Quote

The manufacturing of air cooled condenser is made of modules arranged in parallel rows as like air cooled heat exchanger. The air cooled condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. If your air cooled condensers (acc) are not operating at their optimum they are losing money. by using tube tech international’s innovative air cooled condenser cleaning service lower production rates, higher mechanical costs, higher maintenance costs plus lost time in both machinery and manpower will be problems of the past. Air cooled condenser tube cleaning with specialist industrial cleaning will make a huge difference to your operation. You will increase performance, improve safety, reduce your carbon emissions and reduce overall downtime the major benefits of air cooled condenser are: elimination of additional water usage from the condensing power cycle flexibility in power plant site selection decreased time required for plant permitting the fin tube is the core technology of the air cooled condenser. single-row condensers (src) - an elongated, flat tube with brazed aluminum fins. multi-row galvanized (mrc) - an oval tube with hot-dip galvanized steel fins.

heat recovery systems

Get Price Quote

ELGi offers its Heat Recovery System as an additional gadget with its EG Series compressor. Customers can easily plug the Heat Recovery System to the air compressor and use the heat generated in the air compressor to warm water and air for use in showers and boilers