Automatic Coconut Dehusking Machine

125,000 - 250,000 Per piece

1 piece (MOQ)

Coconut dehusking is the process of removing the husk or outer covering of a coconut fruit. Traditionally, this process has been done manually using tools like machetes or spikes, which requires skill and training. However, there is a shortage of skilled workers, leading to lower production rates and safety hazards.

groundnut decorticator machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Husking Machine

Agriculture paddy separator

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering agriculture paddy separator. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

Arecanut De Husking Machine

80,000 - 150,000 Per Piece

1 Piece(s) (MOQ)

We offer arecanut de husking machine. Hi to all , we are the exports and trading engineering and industrial machine and parts , and now the details for the arecanut de-husk machine , this is used for peeling arecanut and this machine peeled the husk and nut seperat with clear good cut , its peeled fresh arecanut 150kg +- and dry arecanut 125 kg+- per hr , with 1hp motor isi standard and there is different type of machine available , with single conveyer ,4 converyer, 8 conveyer , each convery have 12 blades with and without viberator , any many type availabe 1. De-1 basic model , out put - 150kg hr for fresh and dry 125kg +- 2. De-2 ,2 hp motor,350kg weight, out put 200kg+- fresh and 175kg+- dried 3. De-3 , 2 hp motor, 450 kg weight , out put 250kg+- fresh and 225kg+- 4. De-4 , 3hp motor, 600kg weight , out put 400kg+- fresh and 350kg+- dried

Rice Hulling Machine

Get Price Quote

Keeping pace with the latest market demands, we are a trusted Manufacturer, Exporter and Supplier of premium Rice Hulling Machine. With our team of diligent members, we fabricate sturdily constructed Rice Hulling Machine with longer functional life. Our quality assurance team makes sure that Rice Hulling Machine Providing best quality output, Rice Hulling Machine is available at competitive prices. We are known for timely delivery of all orders.

Husk Buster

Get Price Quote

Buster Machines are super-powerful, The fibres in the husks get softened and straightened to certain extent. Due to this process the hardness of the husks gets reduced and will be easy for further processing. The production capacity is around 4500 husk per hour.

Broken Rice Separator

Get Price Quote

We are offering Lab Model Grader

Husk Aspirator Machine

130,000 Per Piece

Coconut Dehusking Machine

630,000 - 650,000 Per Piece

1 Piece (MOQ)

Salient Features: Capacity up to 1200 coconuts per hour Motor capacity 7.5 HP No breakage of husk Superior quality of material At a time two coconuts are de-husked 100% safe & user friendly Easy maintenance

Automatice Coconut Dehusking Machine

125,000 - 150,000 Per

Arecanut Dehusking Machine

Get Price Quote

1 unit (MOQ)

Coconut Dehusking Machine

150,000 Per Piece

1 Piece(s) (MOQ)

Tamarind Dehuller/Skin/Cover/ Husk removal machine

110,000 Per

1 Kilogram (MOQ)

Groundnut Seed Decorticator Machine

147,000 Per Set

1 Piece (MOQ)

groundnut decorticator machine

Get Price Quote

1 Piece (MOQ)

Coconut Husk Baling Machine

Get Price Quote

Groundnut Decorticator

Get Price Quote

Groundnut Decorticator is used to separate the nuts from the groundnut / peanut shell. Nuts and cord are collected at separate outlets. Model: GD 3200 GD 1200 Capacity: 200 kg/h Suitable for: Groundnut

groundnut decorticator machine

Get Price Quote

A Coir decorticator is a machine for stripping the skin, bark, or rind off nuts in coconut and its preparation for further processing.

Coconut Dehusking Machine

Get Price Quote

We have a team of professionals who keep their vigil eyes on the entire lot that is stored in the warehouse. This unit keeps the lot free from the factors like duct, rain, sunlight, etc. Capable of catering to the varied demands of the customers, we are named amidst the respected Suppliers of Coconut Dehusker Machine.

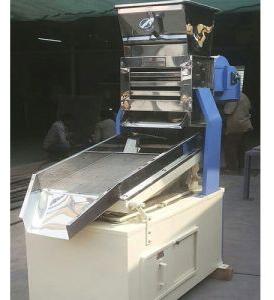

Decorticator Machine

Get Price Quote

The idea of a decordicator is to remove the groundnut from its shells. Our range of Decordicators is engineered at its best function which would give the finest results. The main function of a decordicator is when the groundnut is fed inside the decordicator’s upper chambers, the shell would be immediately removed with the rubber plate which is inside the decordicator and instantly separates the shell and the groundnut. Apart from this, a rubber plate placed inside of a decordicator would separate the fines of groundnut for seed and its crush for oil. The main advantages of having a decordicator in mills is for the extract of the groundnut oil which could then be sent for retail and wholesale. The rubber plates of the decordicator may be worn out after same on usage but it can be replaced from time to time making it even more efficient. The variants of Decordicators available are from 2Hp to 100Hp and the maintenance of these decordicators are quiet simple and is highly user friendly machine.