ductile casting

Get Price Quote

Copper Sand Component Castings

1,760 Per Kilogram

1000 Kilogram (MOQ)

Best Deals from Industrial Casting

Machined castings- Stainless Steel

5,000 Per Kilogram

hs code 73259930.

Sand Casting

Get Price Quote

Sand casting offered by us is well known process that facilitates the less significant batches that is to be made and are compared to enduring mold casting. We offer this process at the market leading prices and also make the fabriSand Mouldion of many products very easy. It benefits sand casting, such as very small size operations and allows many metals to bed casted. Following are the salient features of the process: Mass limit of 2300-2700 kg Minimum part weight ranges from 0.075-0.1 kg Can create the entire bed for one rail carIt is the most popular and most basic of all the casting processes along with being economical. first a cavity in the sane is formed by using a pattern made of wood or metal. The cavity is contained in a flask. Cores are put in the cavity to form holes of the desired shapes. An extra void called Riser is created in the mold to contain excessive molten material. The purpose of this is to prevent voids in the main casting. Generally sand casing consists of a two-part Sand Casting Mold. While the upper part is called the Cope, the lower part is called the Drag. A parting line or surface separates the two. Some portion of the drag is filled with sand. The cores, core print, and the gating system are placed near the parting line. The cope and the drag are assembled then sand is poured in the cope half. That covers the pattern, core and the gating system. The sand gets compacted by vibration and other mechanical processes. After this, the cope is removed from the drag. The pattern is removed. Care is taken so that pattern is removed without breaking the mold cavity. This can be taken care of by designing a draft, which is usually a minimum of 1” or 1.5 mm (0.060 in), more rough the surface of the pattern, the more the draft to be provided.

Industrial Component Die Casting

Get Price Quote

General Engineering Component Castings

Get Price Quote

Backed by a skilled team of professionals, we are offering supreme quality General Engineering Component Castings. For the manufacturing of these General Engineering Component Castings, our dexterous professionals make use of the supreme quality raw materials and sophisticated technology in adherence with industrial set standards and norms of quality and safety.

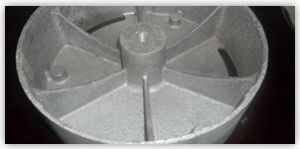

aluminium die casting motor body

Get Price Quote

Aluminium die cast motor body with leg (Horizontal, flexible leg or fix leg type body) / Without leg (vertical) along with terminal box & cover. This motor body are low in weight compare to that of C.I. body, machining friendly – which means fast in production with good painting / coating results. The available frame sizes are from 1063-F, 1071-F, 1080-F, 1090-F, 1100-F in GKW standard design. We also offer body in IEC Standard in 1100-Frame size. All types of spares can be supplied for motor pump

Strainer Body Casting

Get Price Quote

aluminium sand castings

Get Price Quote

In order to gratify the needs of the clients, we engage in providing the finest quality of Aluminium Sand Castings at industry leading prices. We manufacture the Aluminium Sand Castings using the finest raw materials and modern tools under the strict supervision of skilled experts. The Aluminium Sand Castings are famous for having superior strength, majestic shine, and excellent finish. Our unique range of Aluminium Sand Castings is made up of the finest quality, and we guarantee 100% satisfaction to the buyers. Based in Coimbatore, Tamil Nadu, India, we are a leading manufacturer, exporter, and supplier of Aluminium Sand Castings.

aluminium sand castings

Get Price Quote

Stern quality checks, frequent examinations and perfect packaging, we make certain that the range is as per the industrial standards. Located in Coimbatore(India), we have made our distinguished position in the market since our products are qualitative and of utmost standards.

Valve Housing Casting

Get Price Quote

Sand Mold Castings

Get Price Quote

1 Ton (MOQ)

Electric motor body aluminum

1 Per Kilogram

1000 Kgm (MOQ)

Die Casting

Get Price Quote

We also manufacture die casting for machinery parts. Our castings have high operating speed and outstanding corrosion resistance. They are light in weight and possess good strength and hardness.

industrial alloy steel castings

100 - 500 Per Piece

Green Sand Moulding

Get Price Quote

This process derives its name from the presence of moisture in molding sand and is indicator of the unbaked nature of the mould. Raw sand is obtained and processed to provide a consistent distribution of grain sizing. A variety of additives such as pitch, cellulose, and silica flour are used in the process. This process of molding offers a great deal of flexibility in pattern design and consequently in the mould design at very economical costs. At VJP, we have adapted the green sand process to mechanical and automated production methods to ensure speed and efficiency. Features Low material costs Reclaimable mould material. Environmentally friendly. Ensures strong and rigid moulds. Advantages These molds are relatively inexpensive to produce, since the basic material is readily available. Complex patterns can be accommodated in the in the mold design, at affordable costs. Easily adapts to automated production methods.

housing casting

Get Price Quote

Ductile Iron Casting

Get Price Quote

We offer a comprehensive range of ductile iron castings. The weight range of single piece can be up to 2000 kg. These castings can be supplied in both raw casting and fully machined finish. They are durable and ductile in nature. Our provided castings are applied in valves, pumps, general machinery, automotive, locomotive and textile machinery.

Sand Casting

Get Price Quote

Valve Housing Casting

Get Price Quote

shell moulding casting

Get Price Quote

Shell molding, also known as shell-mold casting is an expendable mold casting process that uses a resin covered sand to form the mold. As compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labor requirements. It is used for small to medium parts that require high precision.

low pressure die castings

Get Price Quote

Type of tool : Low Pressure Die castingMould Size :1100X 800 X 550No of Cavities : SingleWeight : 8.6Kg

Safety Valve Casting

Get Price Quote

Sand Casting

Get Price Quote

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed. Sand casting is used to produce a wide variety of metal components with complex geometries like Automotive, Engineering and Other Industries.

aluminium motor body

Get Price Quote

We manufacture different range of aluminium parts which are used for various industrial purposes and they include textile parts, automobile parts, Telecommunications parts, Electrical parts and much more to any field in Engineering.

Permanent Mold Aluminum Castings

Get Price Quote

Iron Ring Casting

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Aluminum Sand Casting

Get Price Quote

We are looked upon as one of the stupendous Aluminum Sand Casting Manufacturers & Exporters from India. The Aluminum Sand Castings, offered by us, are widely appreciated in the market as no alternative is available in terms of quality and performance. Applications : Pump IndustryValves IndustryLift IndustryExcavatorsMaterial Handling EquipmentAutomotive IndustryConveyor IndustryGear BlanksReduction Gear BoxesEngineering Bushes Attributes : Single casting of around 300kg

Ductile Iron Casting

Get Price Quote

MOULD STICK

Get Price Quote

We are the main supplier of this product.