Casting Gents Gold Ring

Get Price Quote

Manish Jewellery is the best manufacturer of Casting Gents Gold rings in Tamil Nadu, India. We are accomplished in making an accessible alluring assortment of Gold rings at the market driving costs. These Gold Rings are well known because of their rich look. We guarantee that these Gold Rings are painstakingly tried in our research centres to deliver a veritable assortment to the clients. Gold Ring, we offer, is liked for making each event exceptional. Features : Exquisite look Sturdy Designing Lustrous sparkle Quality tested We are reliable and the best Men Gold Ring Supplier in the country and we offer our customers the best products. We have a list of brilliant jewellery for our customers to choose from. Order now.

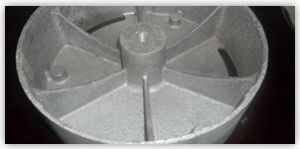

Alloy Housing Body

Get Price Quote

We are well-reckoned as one of the supreme Alloy Housing Body Exporters from India. Customers from all round the globe are placing repeated orders for the Housing Body due to applicability in Machinery Parts. Moreover, customers are eased with the availability of the Cast Aluminium Alloy Housing Body in varied sizes and dimensions as per the specifications provided.

Best Deals from Industrial Die Casting Components

Aluminium Gravity Die Castings

180 - 210 Per kgs

1000 Kilogram (MOQ)

Die Casting

Get Price Quote

We also manufacture die casting for machinery parts. Our castings have high operating speed and outstanding corrosion resistance. They are light in weight and possess good strength and hardness.

Sand Casting

Get Price Quote

Sand casting offered by us is well known process that facilitates the less significant batches that is to be made and are compared to enduring mold casting. We offer this process at the market leading prices and also make the fabriSand Mouldion of many products very easy. It benefits sand casting, such as very small size operations and allows many metals to bed casted. Following are the salient features of the process: Mass limit of 2300-2700 kg Minimum part weight ranges from 0.075-0.1 kg Can create the entire bed for one rail carIt is the most popular and most basic of all the casting processes along with being economical. first a cavity in the sane is formed by using a pattern made of wood or metal. The cavity is contained in a flask. Cores are put in the cavity to form holes of the desired shapes. An extra void called Riser is created in the mold to contain excessive molten material. The purpose of this is to prevent voids in the main casting. Generally sand casing consists of a two-part Sand Casting Mold. While the upper part is called the Cope, the lower part is called the Drag. A parting line or surface separates the two. Some portion of the drag is filled with sand. The cores, core print, and the gating system are placed near the parting line. The cope and the drag are assembled then sand is poured in the cope half. That covers the pattern, core and the gating system. The sand gets compacted by vibration and other mechanical processes. After this, the cope is removed from the drag. The pattern is removed. Care is taken so that pattern is removed without breaking the mold cavity. This can be taken care of by designing a draft, which is usually a minimum of 1” or 1.5 mm (0.060 in), more rough the surface of the pattern, the more the draft to be provided.

Aluminium Die Castings

Get Price Quote

Due to the dedicated support of our well-trained workers, we deliver a diverse range of Aluminium Die Castings at competitive rates. Being a key manufacturer, supplier and exporter of Aluminium Die Castings, we offer dimensionally accurate castings to the clients. Before supplying the castings, we check the quality and other specifications. While the Aluminium Die Castings promises high performance and maximum output, we carefully process these to ensure uniformity in the products. We are based in Coimbatore, Tamil Nadu, India.

Press Tool Dies

Get Price Quote

Press Tool Dies

Get Price Quote

Our company is capable of delivering consignments on time owing to an efficient trading network we have. To pack our products, we have ultramodern machines. The packaging materials are nontoxic, sturdy and reliable. The products remain safe and undamaged in our packaging.

Blanking Dies

Get Price Quote

Features : Quality approved Perfect finish Fine quality

aluminium casting parts

Get Price Quote

Material : Aluminium alloyS ADC12, ADC10, A360, A380, A356, A413, LM0, LM2,LM4,LM6,LM9,LM25 etc. Part Weight: from 350g --- 200kg or Customized Thickness: 0.4mm-20mm or Customized Deep Processing: CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling

Aluminium Pressure Die Casting

80 - 10,000 Per Piece

100 Piece(s) (MOQ)

Aluminium Die Cast Rotors for -Motors -Pumps & Rotational equipments

Pressure Vessels

64,777 Per Piece

1 Piece(s) (MOQ)

We are a company which is well known in the market for the supply, manufacture and the export of anwe are a company which is well known in the market for the supply, manufacture and the export of an.

Press Tool Dies

35,000 - 50,000 Per Piece

1000 Piece (MOQ)

Aluminium Gravity Die Castings

Get Price Quote

We offer Aluminium Gravity Die Castings in different sizes and shapes to meet the varied requirements of the cl;ients. The major concern of our firm is to deliver a quality content, thus, we check the product quality on several counts at all stages. We abide by the strict delivery policies and thus, we ensure that the products are sternly packed and delivered on time.

castings components

Get Price Quote

Aluminium Die Casting Part

Get Price Quote

Blanking Dies

Get Price Quote

We offer q designs & products manufactures blanking dies, piercing dies, punching dies, cutting dies, bending dies, etc. For all sheet metal applications. These dies ensure high accuracy, long working life and consistent quality of output products.

Gravity Die Castings

Get Price Quote

1 Ton (MOQ)

cast iron castings

Get Price Quote

We are dedicatedly engaged in providing a wide array of Cast Iron Castings. Due to features like high durability, low maintenance and fine quality, our Cast Iron Castings are widely demanded in cement, chemical, engineering and automotive industries for various applications. Due to the low melting point, castability, good fluidity, resistance to deformation and wear, Cast Iron Castings are used as engineering material and in machines, pipes, automotive industry parts, etc. Cast Iron Castings are resistant to destruction and oxidation as well. Highlights : Sturdy construction Highly durable Low maintenance Corrosion resistance

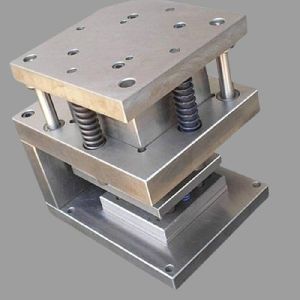

Die Sets and Components

Get Price Quote

MDL Die Sets, Components and Compression Springs have been supplied to the metal stamping industry for more than 40 years, always manufactured to the highest standards of quality, committed lead times and customer service to the ultimate satisfaction of our customers. MDL can supply die set needs in different ways. Standard die sets, as shown in our catalogue, are in stock and ready for assembly and dispatch within 2 working days. We hold a large stock of die plates and guiding components ready for assembly according to our customer’s requirements. The second option is “customised die set” made to your own specifications and measurements. We have the ability and equipment to make die sets of practically any size or complexity according to your requirements. (taped hole, mounting screw holes, slug hole, socket head screw, counter bore /recesses, ramps, pillar and bush bore, clamping pockets etc)

hot chamber die casting

Get Price Quote

Over the past three decades, we are expertise in manufacturing zinc components with hot chamber die casting machines. Out production unit is capable of molding components weighing from 0.5 gms to 2000 gms. We have mastered in molding intricately shaped casting with our expert production team.

Gravity die casting

Get Price Quote

This process is used for casting low melting point material such as aluminium, copper and magnesium. By pouring the metal in tilted position of the die, the feed rate is reduced. This decreases turbulance and foaming of liquid metal. Tilting helps in smooth flow of metal in the die, thus oxidation is reduced considerably. Using sand cores complex geometries can be casted. The resulting cast has high surface finsih and close tolerance.

Iron Ring Casting

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Casting Components

Get Price Quote

We have gained expertise in retailing and wholesaling a wide range of casting components.

Aluminium Die Casting

Get Price Quote

Due to the dedicated support of our well-trained workers, we deliver a diverse range of Aluminium Die Castings at competitive rates. Being a key manufacturer, supplier and exporter of Aluminium Die Castings, we offer dimensionally accurate castings to the clients. Before supplying the castings, we check the quality and other specifications. While the Aluminium Die Castings promises high performance and maximum output, we proudly announce our castings are supplied to Indian army.We are based in Coimbatore, Tamil Nadu, India.

Sand Casting

Get Price Quote

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed. Sand casting is used to produce a wide variety of metal components with complex geometries like Automotive, Engineering and Other Industries.

precision die casting

Get Price Quote

Investment Casting Dies

Get Price Quote

We offer a wide range Dies for investment castings to be used with different industries. These dies are manufactured using advanced technology and by using high quality raw materials to ensure total satisfaction to our customers.

Pressure Vessels

Get Price Quote

Pressure Vessels are used for compressed air storage and are recommended to be in all compressed air systems for pulsation free discharge and to save energy if sized properly. Using pressure vessels of unsound or questionable construction can be very dangerous. Summits adopts stringent manufacturing standards and practices. Features • Pressure Vessels can be supplied according to ASME - U / CE-PED standards • Custom built designs • Statutory third party inspection as option

Pressure Vessels

Get Price Quote

We Heat Transfer Equipments Pvt ltd extend our global services with design and manufacturing of all types of pressure vessels for the Industries with (or) with out U stamp as required. Below are some of pressure vessels up to 250 bar pressure can be manufactured in Heat Transfer Equipments Pvt Ltd. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Generally, a pressure vessel is considered to be thin-walled if its radius is larger than 5 times its wall thickness. There are many types of pressure vessel they are Thin Walled Pressure Vessel, Thick Walled Pressure Vessel, Strong Tanks Pressure Vessel, Transportable Containers, Propane bottles and gas cylinders. Pressure Vessel Application Pressure Vessels for Water Treatment Plants Gas Storage Vessels Pressure Vessels for Refrigeration & Cryogenic Pressure Vessels for Shipping Industry Uses of pressure vessels The pressure vessels are used fluid to store such as liquid vapors and gases under pressure. Major uses of pressure vessels are as follows. Pressure vessels are used in steam boilers Pressure vessels are also used in storage of chemical in chemical plants Use in storage of petroleum products (petrol, diesel etc) It is also used in engine cylinders.